"At ITMA, Stäubli is exhibiting a wide range of machinery equipped with state-of-the-art high-end technologies and software solutions that offer new and expanded benefits to textile mills. Stäubli solutions can boost weaving or sock-knitting performance and overall mill efficiency, besides offering decisive functional advantages. The new generation machines on offer are:"

At ITMA, Stäubli is exhibiting a wide range of machinery equipped with state-of-the-art high-end technologies and software solutions that offer new and expanded benefits to textile mills. Stäubli solutions can boost weaving or sock-knitting performance and overall mill efficiency, besides offering decisive functional advantages. The new generation machines on offer are:

At ITMA, Stäubli is exhibiting a wide range of machinery equipped with state-of-the-art high-end technologies and software solutions that offer new and expanded benefits to textile mills. Stäubli solutions can boost weaving or sock-knitting performance and overall mill efficiency, besides offering decisive functional advantages. The new generation machines on offer are:

SAFIR S60 automatic drawing-in system with ‘Active Warp Control’

The SAFIR series of drawing-in systems offers unique advantages thanks to AWC (Active Warp Control), Stäubli’s exclusive yarn-repeat management system. The precision of this ingenious technology leads to more first-quality output, supports on-time delivery, and boosts the overall productivity of the weaving department. AWC is based on optical, non-contact recognition and measurement of yarn characteristics using two cameras.

Stäubli’s exclusive yarn-repeat management system. The precision of this ingenious technology leads to more first-quality output, supports on-time delivery, and boosts the overall productivity of the weaving department. AWC is based on optical, non-contact recognition and measurement of yarn characteristics using two cameras.

New S1792 cam motion expands the broad range of frame-weaving solutions

Stäubli’s frame-weaving solutions are renowned for reliable high-speed weaving and adaptability to any kind of plain or patterned fabric and any kind of weaving machine. This versatility, in conjunction with robustness and high quality, has made the broad range of 1600/1700 series of cam motions and the S3000/S3200 series of electronic rotary dobbies well known as extremely reliable workhorses

LXXL Jacquard machine with NOEMI electronic system for luxury and technical fabrics

The LXXL machine boasts a large format (up to 25,600 hooks or 51,200 hooks in a tandem installation), for flat, terry, and velvet fabrics. It is dedicated to luxury and high-quality fabrics for clothing, upholstery silk weaving, bed linen, coverings, and technical applications.

Like the LX/LXL, the LXXL features lifting motion that ensures precise shedding geometry and absolutely vibration-free movement even at high speeds. The optimally coordinated kinematics of all moving parts within the machine and the directly mounted components such as the drives enable routine weaving of very heavy fabrics.

New-generation machine for selvedging

The N4L is Stäubli’s latest answer to the challenges of selvedge weaving, allowing the weaving of complicated patterns at the highest speeds using the most delicate and precious yarns for high-fashion fabrics. The machine is available in two formats: 80 or 128 hooks. It features robust construction and dust-proof design.

ALPHA 500 series of Schönherr carpet systems

The ALPHA 500 carpet weaving system adds immense flexibility to any carpet-weaving mill. It weaves the highest-quality applications and allows responding swiftly to rapidly changing market demands. Visitors may observe the high-performance operation up close, including the latest servo-controlled dobby of the UNIVAL 500 series and the unique servo cutting device that produces carpet surfaces of unequalled evenness.

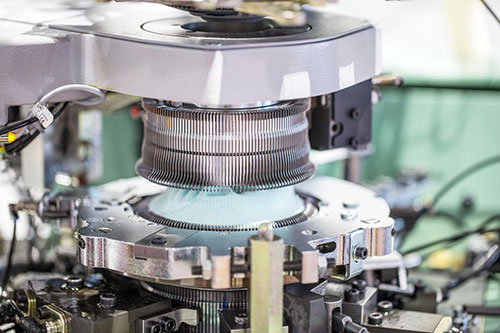

Knitting solutions: D4S toe closing device shortens sock production

Stäubli’s D4S automatic toe closing device rapidly closes the sock on the knitting machine with a smooth seam, significantly shortens sock production, ensures top quality and uniformity of the product, and makes for very short idle times. The automatic sock pick-up and seaming operations are electronically controlled by the 2900SL controller, and this setup will boost the performance of any mill producing socks, woollen stockings, pantyhose, or medium-to-large diameter knitted goods used in various sectors.

Stäubli Robotics presents HelMo, the mobile robot system

HelMo is an autonomously driving and navigating vehicle developed especially for human-robot collaboration. At ITMA, HelMo will be at work replacing bobbins. Thanks to its modular design and robust drive technology, it can be used in virtually any industrial area, including, logistics, assembly, and quality control.

Stäubli has the core competencies in shedding (cam motions, dobbies, and Jacquard machines) and weaving preparation (drawing-in, leasing, and warp-tying machines.