FW

High-performance textile landscape is undergoing a significant geographic and sectoral shift this January as powered by Performance Days, the Functional Fabric Fair launches its first-ever Winter Edition in Orlando, Florida. Strategically co-located with the PGA Show at the Orange County Convention Center on January 21–22, 2026, the event marks a major integration of technical material innovation into the $102 billion global golf industry. With over 90 curated exhibitors, the fair aims to bridge the gap between traditional golf aesthetics and the rigorous technical demands of modern outdoor and activewear.

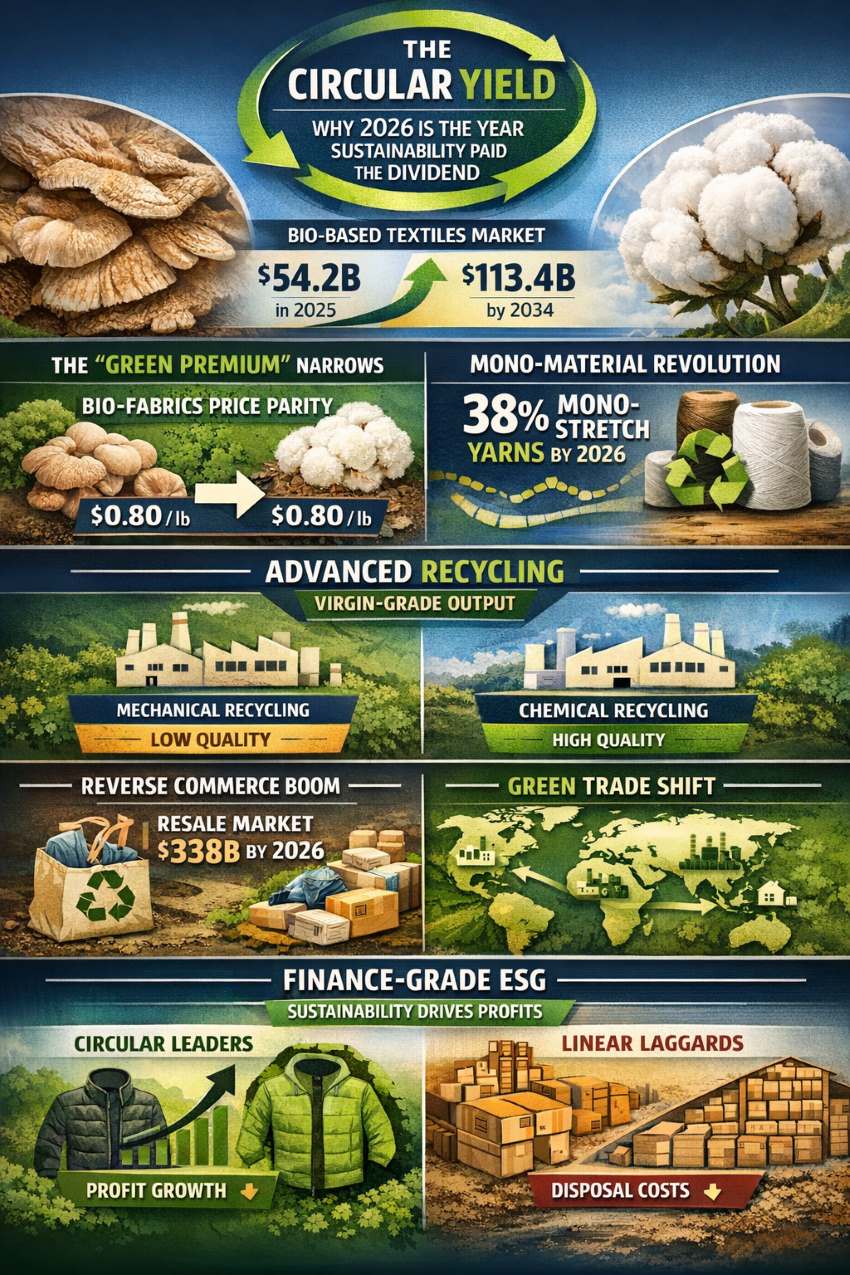

Circularity and the rise of textile-to-textile recycling

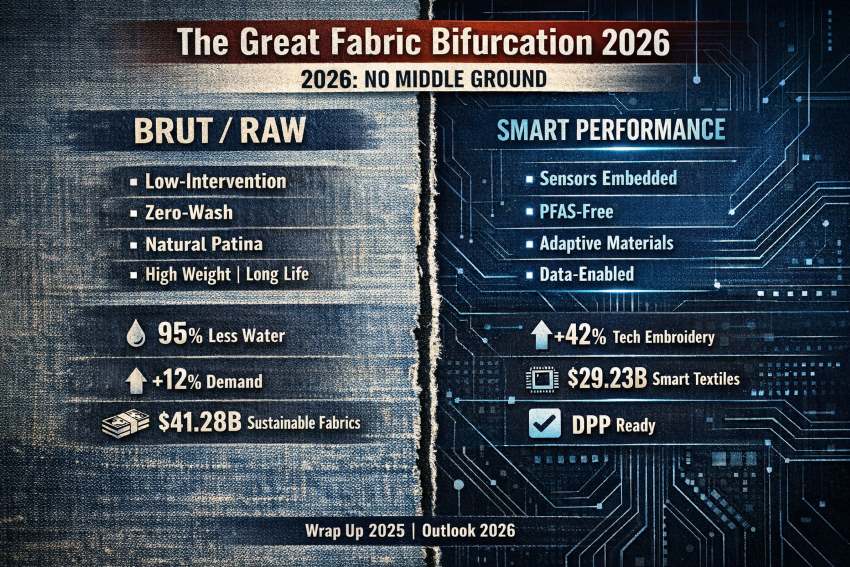

A primary commercial driver for this edition is the rapid maturation of the textile recycling market, which is projected to grow from $1.7 billion in 2026 to $8.5 billion by 2035. The fair’s educational programming focuses heavily on Textile-to-Textile (T2T) recycling, a process essential for brands navigating new sustainability mandggates. Industry leaders are presenting advancements in chemical and enzymatic recycling that allow for high-quality fiber recovery from complex blends - traditionally a major hurdle for performance apparel. The transition to a circular model is no longer optional; it is a prerequisite for Tier-1 global partnerships, noted a sector analyst during the preliminary Trend Forum.

Engineering the future of performance golf wear

The synergy between the Functional Fabric Fair and the PGA Show reflects a broader trend where performance-driven and eco-friendly apparel accounted for 22 per cent of new product launches in 2025. Golf brands are increasingly adopting technologies like UV protection, cooling fibers, and PFC-free water repellency once reserved for extreme mountain sports. With North America dominating 38.5 per cent of the golf apparel market, the Orlando debut provides a critical sourcing node for designers. By placing vetted global suppliers directly in front of the golf industry’s largest buying cohort, the event facilitates a more efficient supply chain, allowing brands to implement sustainable innovations at scale without compromising the "hand-feel" or durability expected by the premium consumer.

Functional Fabric Fair is a trade-exclusive sourcing platform dedicated to high-performance functional fabrics, finishes, and trims. It serves the outdoor, activewear, and lifestyle markets, focusing on curated mills that meet strict sustainability and performance criteria.

In a decisive move to address the challenging economic landscape in the world’s second-largest economy, IKEA China has announced the closure of seven large-format stores effective February 2, 2026. The restructuring targets sites in secondary markets and suburban districts, including Shanghai Baoshan, Guangzhou Panyu, and Harbin, as the retailer grapples with a prolonged property slump that has dampened furniture demand. As home prices declined by nearly 10 per cent in 2025 and new home sales projected to decline by another 15 per cent, the Swedish giant is shifting its capital from expansive warehouses to high-density urban centers and digital flagships.

Precision penetration in Tier-I hubs

Rather than a full-scale withdrawal, IKEA is shifting to ‘precise cultivation,’ committing 160 million yuan in FY26 to enhance affordability through strategic price investments. The company plans to open more than 10 small-format ‘Plan and Order’ points over the next two years, specifically targeting Beijing and Shenzhen. A new urban outlet is slated for Dongguan this February, followed by a launch in Beijing’s Tongzhou district in April. This model aims to reduce logistics overhead while meeting the instant-delivery expectations of Chinese urbanites, a market where IKEA’s online business now accounts for over 25 per cent of total revenue.

Digital synergy and omnichannel integration

Launched in August 2025, the retail giant’s partnership with JD.com has become a cornerstone of its resilience strategy, enabling rapid fulfillment across major metropolitan areas. Despite the store closures, IKEA’s omnichannel visitors rose 4.7 per cent to 477 million in the last fiscal year, signaling that while physical footprints are shrinking, brand engagement is deepening digitally. The retailer now focuses on being closer to the consumer through a mix of curation and rapid logistics, notes a market analyst. By integrating its presence on Tmall and JD.com with physical pickup points, IKEA is navigating a supply-demand mismatch that has seen local online furniture brands erode the market share of traditional blue-box outlets.

As a leading global home furnishing retailer, IKEA provides affordable, functional design across 34 remaining physical outlets in mainland China. The brand is currently focusing on ‘Life at Home’ innovations and sustainable, localized product lines to drive a 7 per cent–9 per cent projected revenue recovery in FY2026. Since entering China in 1998, IKEA has evolved from a suburban destination to an omnichannel lifestyle platform.

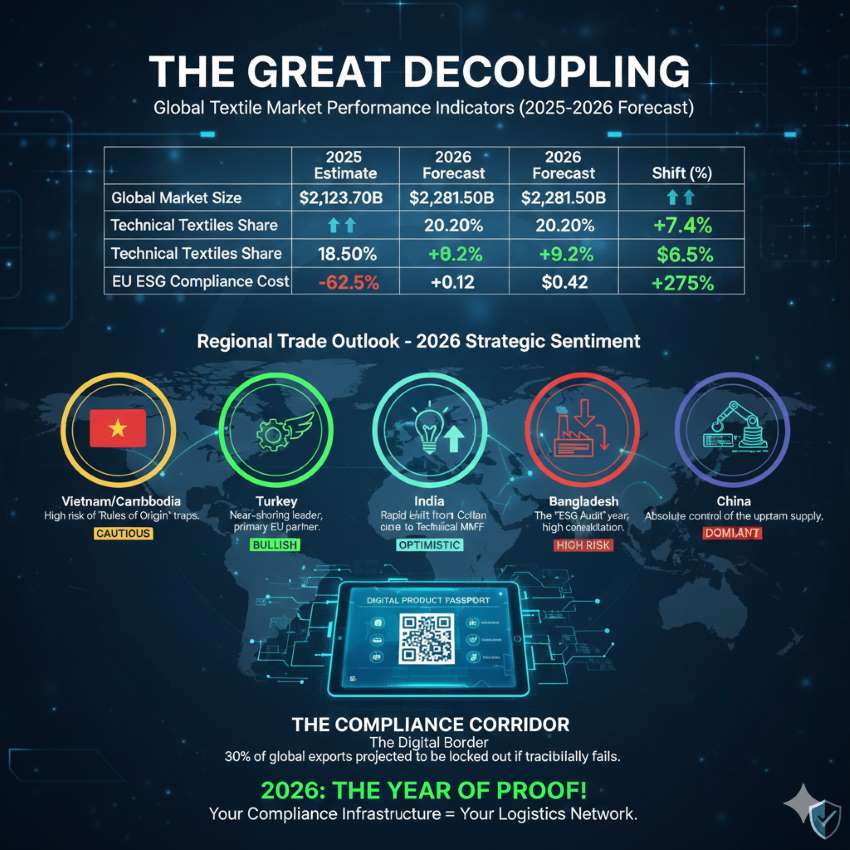

Vietnam’s textile and garment industry concluded 2025 with an export turnover of approximately $46 billion, marking a 5.6 per cent Y-o-Y increase. While this performance solidifies the nation’s status as the world’s third-largest exporter - trailing only China and Bangladesh - the final figures fell slightly short of the initial $48 billion industry target. This marginal shortfall is attributed to significant international policy transitions and a regime of aggressive US tariffs that disrupted seasonal order flows. Despite these macro-volatilities, the sector maintained a robust trade surplus of $21 billion, reaffirming its position as a primary pillar of the national trade balance.

Divergent trends in yarn and apparel

A notable trend in the 2025 data is the divergence between finished goods and raw materials. Apparel shipments dominated earnings, contributing roughly $38 billion to the total. Conversely, the yarn segment faced intense downward pressure; while export volumes rose, the total value of yarn exports declined. This ‘volume-value gap’ reflects a surplus of supply in regional spinning markets and stiff price competition from China and India. The current landscape forces us to shift from a high-volume model to value-driven manufacturing, stated Truong Van Cam, General Secretary, Vietnam Textile and Apparel Association (VITAS). This shift is evident in the 2026 outlook, where many enterprises have secured orders through Q1 by focusing on higher-margin, specialized technical textiles.

Strategic sourcing and the green transition

The industry is proactively preparing for a high-output 2026, evidenced by a sharp year-end increase in cotton and yarn imports. With a domestic localization rate now reaching 52 per cent, manufacturers are still importing nearly 70 per cent of high-grade raw materials to meet stringent rules of origin required by the EVFTA and CPTPP. Opportunities in the coming year are concentrated in ‘green’ manufacturing. To retain Tier-I global clients, Vietnamese firms are investing heavily in water-recycling systems and solar-powered facilities. As 2026 begins, the sector is increasingly moving toward a ‘multi-pillar’ model, diversifying into technical sportswear and medical textiles to hedge against concentrated market risks in the US and EU.

In a strategic move to dominate the high-margin functional accessories sector, Centric Brands announced its acquisition of key assets from Fownes Brothers & Co this January. By absorbing the intellectual property and operational infrastructure of the 249-year-old glove specialist, the New York-based brand collective has secured lucrative licensing rights for Ugg, Timberland, and Cole Haan. Furthermore, Centric assumes critical private-label manufacturing agreements with performance giants Lululemon and The North Face. This consolidation arrives as the global winter wear market is projected to reach $447.8 billion by 2035, with North America alone accounting for over 42 per cent of the sector's current expansion.

Vertical integration and operational efficiency

The acquisition facilitates a direct infusion of technical expertise into Centric’s existing accessories platform. Andrew Gluckman joins as Senior Vice President and Division Head of Cold-Weather, ensuring that Fownes’ centuries-old ‘legacy of the loom’ is maintained within a modern, AI-driven corporate structure. Centric’s proprietary ‘Trend Pulse’ platform - which analyzes over 5 billion real-time data points - will now be applied to the newly acquired licenses to optimize inventory turnover and reduce time-to-market by an estimated 30 per cent. This data-led approach is essential to maintaining Centric's 2024–2027 roadmap, which targets a net sales compound annual growth rate of 6 per cent to 8 per cent, aiming for $3.4 billion in revenue by 2027.

Navigating volatility in a premium segment

Industry analysts suggest, the ‘Fownes Integration’ serves as a strategic hedge against the rising raw material costs currently squeezing the middle-market apparel sector. While domestic fiber availability fluctuates, the premium cold-weather category remains resilient, driven by a 15 per cent increase in consumer spending on high-performance lifestyle gear. Centric is positioning itself to leverage these world-class licenses across mass-market, specialty, and e-commerce channels. By consolidating these high-tenacity brands under one operational umbrella, Centric intends to deliver a 200 basis point annual margin expansion, proving that even in a volatile retail climate, category leadership and technical heritage remain the ultimate commercial currencies.

Centric Brands is a leading lifestyle collective that designs, sources, and distributes apparel and accessories across 100+ owned and licensed brands. Key categories include kids, men's, and women's apparel, with major licenses like Tommy Hilfiger, Calvin Klein, and Michael Kors.

The global textile and apparel industry is undergoing a structural realignment as New York cotton futures maintain an eight-week peak of 65.76 cents per pound as of early 2026. Fueled by supply constraints in the United States and Brazil, this upward trajectory is fundamentally altering procurement logic. Historically, apparel manufacturers migrated toward synthetic fibers to mitigate costs; however, current energy market volatility- linked to geopolitical instability in South America—has inflated polyester production expenses. Consequently, the price delta between natural and man-made fibers is contracting, prompting a strategic return to cotton-rich blends for high-volume retail lines.

Supply deficits drive strategic procurement

The MY 2025/26 is characterized by a ‘flight to quality’ amidst tightening availability. While global production is estimated at 119.8 million bales, the United States has seen harvested areas decline to nearly 1.45 million acre - a decade-level low - as growers prioritize higher-margin commodities like soybeans. This supply-side pressure is exacerbated by intensive short-covering in the futures market. Market analysts indicate that the current rally is less about a surge in consumer demand and more a result of institutional investors liquidating large short positions as they hedge against anticipated acreage reductions in key exporting regions.

Manufacturing localization and sector impact

For the $1.91 trillion global apparel market, these fluctuating input costs necessitate more resilient supply chains. Projected to reach $17.52 billion by 2033, the Indian sportswear segment serves as a primary example of this shift toward vertical integration. Brands are increasingly adopting localized manufacturing models to insulate themselves from currency fluctuations and logistical bottlenecks. This move towards ‘near-shoring’ is paired with a growing investment in regenerative agriculture, as retailers seek to secure long-term raw material supplies while meeting stringent global sustainability mandates.

The global outdoor sports apparel market is undergoing a fundamental transformation as it reaches a projected valuation of $25.9 billion by the end of 2026. Maintaining a steady compound annual growth rate (CAGR) of 6.8 per cent, this growth is no longer merely a byproduct of increased fitness awareness. Instead, it is being propelled by a sophisticated convergence of textile engineering and digital health. Industry data indicates that the adoption of advanced fabric technologies has increased by 15 per cent Y-o-Y, as consumers increasingly demand garments that offer more than basic weather protection.

Smart textiles and thermal regulation systems

A primary catalyst for this expansion is the integration of ‘intelligent’ fibers capable of autonomous thermal regulation. Leading manufacturers are now deploying moisture-wicking microfibers and UV-protective finishes as standard features. Recent market intelligence reveals a 20 per cent increase in demand for sustainable performance wear, forcing brands to optimize their supply chains for recycled polyester and bio-based synthetics. This shift is particularly evident in the ‘Everyday Adventure’ category, where technical apparel is engineered for both high-intensity mountaineering and urban environments, effectively blurring the lines between functional gear and daily fashion.

Regional growth and strategic localization

The Asia-Pacific region is emerging as the fastest-growing geographical segment, fueled by rising middle-class disposable incomes and a 171 per cent increase in hiking participation since 2020. To mitigate global logistical risks, major players are shifting toward localized manufacturing hubs. For instance, contract manufacturers are expanding BIS-certified facilities to serve athletic giants like Adidas and Puma domestically. Despite challenges such as raw material price volatility for nylon and spandex, the sector’s focus on high-margin, multi-functional products - such as 2-in-1 hybrid leggings and convertible modular jackets—continues to secure robust financial performance across global retail channels.

The outdoor performance apparel industry specializes in technical clothing for hiking, cycling, and adventure sports. Focused on North American and Asia-Pacific markets, the sector is currently scaling smart-textile integration and sustainable production lines. Following a record 25 per cent growth in e-commerce sales, the industry outlook remains bullish, supported by a century-long evolution from basic wool layers to high-tech, GPS-integrated wearables.

Asics Corporation is scaling its global R&D footprint, committing $25 million to establish its first-ever American research facility. Based in Ann Arbor, Michigan, the Asics Institute of Sport Science (ISS) America marks a significant shift in the Japanese brand's strategy to localize innovation for its largest growth market. In partnership with the University of Michigan, the center will operate as the ‘Asics-Michigan Sport Innovation Center,’ uniting biomechanics, robotics, and AI-driven textile engineering to engineer the next generation of performance apparel and footwear.

Engineering the future of high-performance retail

This move is a cornerstone of the company’s Mid-Term Plan 2026, which prioritizes a ‘Global x Digital’ approach to reclaim leadership in the premium running category. By embedding researchers within the US sports ecosystem, Asics aims to reduce the product development cycle through rapid prototyping and real-time data from elite North American athletes. The facility will house a dedicated sports lab focused on bioengineering and AI-driven design, moving beyond traditional shoe-making into ‘human-centric science’ that analyzes how specific materials interact with the human nervous system and movement patterns.

Strategic market capture and financial resilience

The investment follows a period of robust fiscal health for the brand. Asics reported a 21.3 per cent global sales increase in late 2025, with North American net sales rising nearly 8 per cent Y-o-Y. As competition intensifies from digital-first entrants and established rivals, the Michigan hub provides a critical competitive moat. ‘Establishing this research entity in the United States—home to a key market for our future growth - is a source of great pride,’ states Mitsuyuki Tominaga, President and COO, Asics Corporation. The move is expected to drive operating margins toward a target of 17 per cent, leveraging high-margin performance lines like the Gel-Nimbus and Metaspeed series.

Asics is a leading designer of performance athletic footwear and apparel, operating across North America, Europe, and Asia. Under its 2026 growth roadmap, the company is targeting record operating income of 130 billion yen ($860 million approx.) by 17 per cent margin optimization. Founded in 1949 as Onitsuka Co, the brand remains synonymous with technical excellence in marathon running and core performance sports.

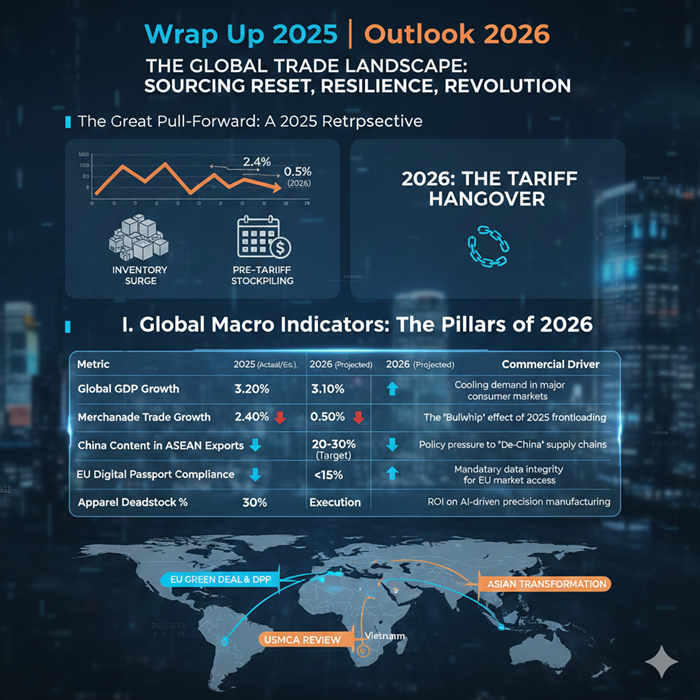

This feature marks the final installment of our special series, Wrap Up 2025 | Outlook 2026, exploring the tectonic shifts in global commerce.

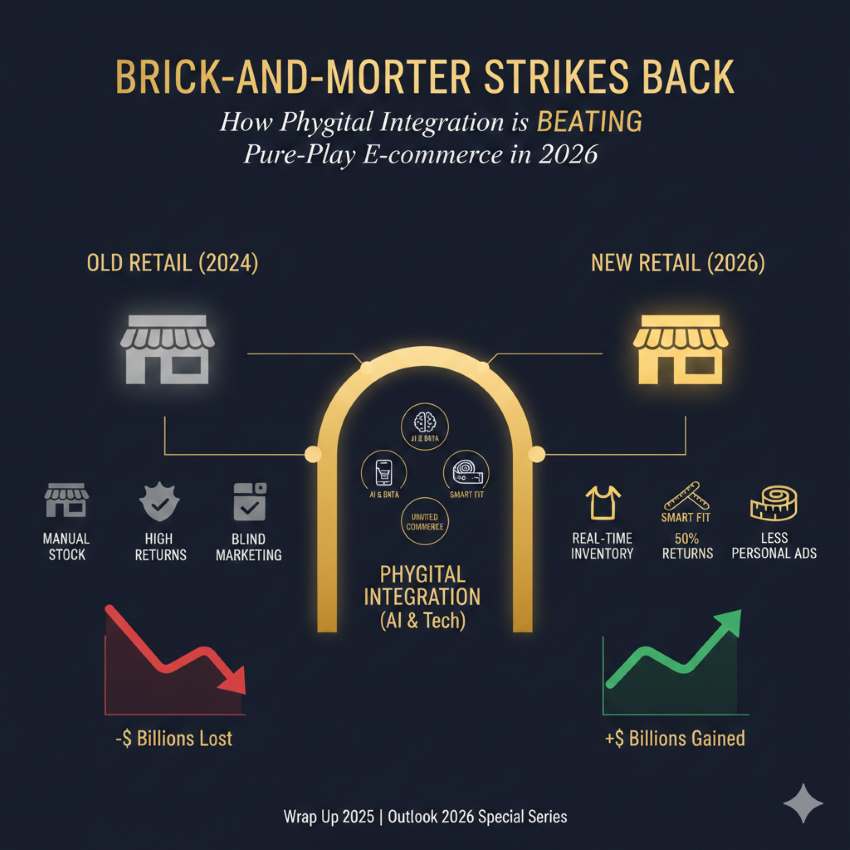

For a decade, the narrative of fashion retail was a eulogy for the physical store. The "Retail Apocalypse" was supposed to be the final chapter for brick-and-mortar, as algorithms and one-click checkouts moved the theater of consumption to the palm of the hand. But as we enter 2026, a surprising plot twist has emerged. Artificial Intelligence, the very force that threatened to digitize fashion out of existence, has become the savior of the storefront through a seamless phygital integration. In the flagship boutiques of Milan, the high-street staples of London, and the sprawling malls of New Jersey, the "Smart Store" is no longer a concept, it is a high-performance engine. By weaving AI into the literal and figurative fabric of the business, retailers are finding that the most potent version of technology isn’t one that replaces the human experience, but one that creates a phygital ecosystem that is hyper-efficient and deeply personal.

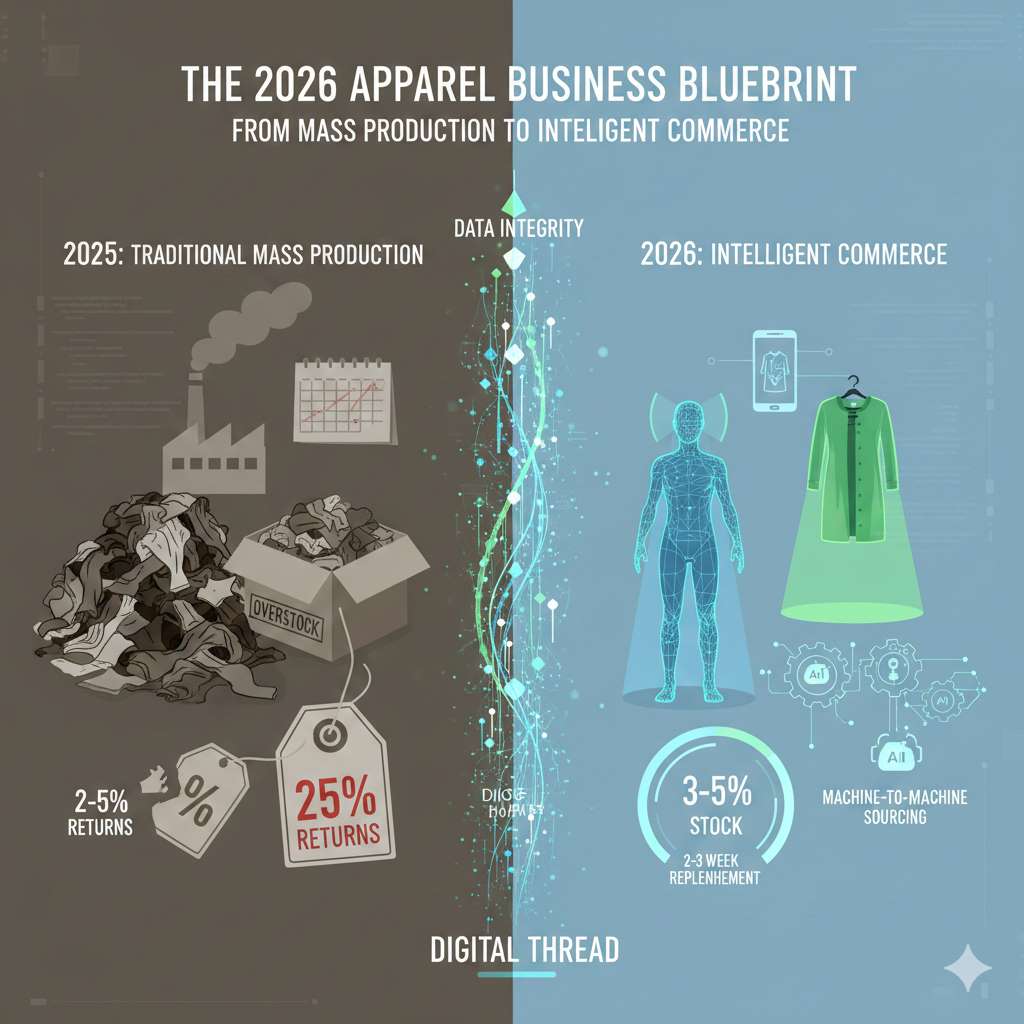

Ending the guesswork in buying and stocking

The most radical transformation is happening where the customer never looks: the warehouse and the back office. Historically, fashion has been a game of "guess and distress", buyers guessed what would be hot, and retailers sold the excess at a loss. Today, AI has replaced the crystal ball with a data-driven compass that synchronizes online trends with physical shelf space. At the sourcing level, high-level logistics systems now monitor global shifts, weather patterns, and shipping bottlenecks to reroute goods before a delay even occurs. In 2026, the gap between a trend appearing on social media and the physical garment arriving on a shelf has shrunk from months to mere weeks. Inside the store, the change is palpable. Sensors paired with computer vision systems mean "out of stock" is becoming an archaic phrase. AI-driven demand forecasting now analyzes local events; a concert across the street or a sudden drop in temperature, to prompt immediate shelf replenishment. For the offline retailer, this means the billions annually lost to overstock and stockouts is finally being reclaimed.

Solving the "Fit Crisis" and slashing return rates

Perhaps the most significant breakthrough in 2026 is the technological conquest of the "Fit Issue" through phygital innovation. For decades, inconsistent sizing across brands was the primary driver of customer frustration and a staggering 30% or more return rate in e-commerce. AI has finally bridged this gap by turning the physical store into a precision-measurement hub for the digital world. High-street retailers have replaced traditional tape measures with 3D Body Scanning booths and AI-powered "Fit Concierges." These systems capture thousands of data points in seconds, creating a "Digital Twin" of the shopper. When a customer stands before an AI-integrated smart mirror, the system doesn't just show them the garment; it calculates the exact drape, tension, and movement of the fabric against their specific body shape. This "True-to-Size" matching has migrated from the shop floor to the user’s mobile app, ensuring that when they later shop online, they are only shown items guaranteed to fit. By solving the fit problem in the physical store, retailers have seen a dramatic 50% drop in returns, protecting margins that were previously eroded by "bracketing", the habit of customers buying three sizes of the same item and returning two.

Knowing the customer better than they know themselves

The power of AI in 2026 lies in its ability to move beyond basic age and gender categories. Traditional marketing focused on broad groups, but AI-driven positioning instead focuses on specific shopping behaviors across the phygital divide. By analyzing billions of data points across social media, search history, and in-store foot traffic, brands can now identify niche audiences and tailor their entire brand identity to resonate with a specific lifestyle. This precision has transformed marketing from an expensive shot in the dark into a surgical strike. In the offline world, this translates to "Hyper-Local Merchandising." An AI analysis of a store’s specific neighborhood might reveal that local shoppers prefer muted tones and structured silhouettes, leading the brand to curate that specific branch’s inventory to match the local style pulse. This level of positioning ensures that the store isn't just a place to buy clothes, but a reflection of the community it serves.

Converting window shoppers into buyers

Walk into a premier fashion outlet today, and the experience is supported by sophisticated systems integrated into smart mirrors and staff tablets. Marketing has moved from shouting at everyone to whispering to the individual, creating a personal phygital journey. Offline stores now use secure, opt-in technology to recognize loyal customers and offer them personalized deals the moment they step through the door. If a shopper browsed a specific suede jacket online but didn't buy it, the in-store smart mirror might suggest a matching silk scarf when they enter the fitting room, offering a real-time bundle discount. This synergy between online data and offline presence has turned the fitting room, once the bottleneck of the retail experience, into a high-conversion discovery zone. Furthermore, tools now allow floor managers to monitor the "emotional temperature" of the shop. By analyzing movement patterns and dwell times, AI can flag if a particular section is causing frustration or if a display is being ignored, allowing for immediate changes to the store layout.

The New Math: Comparing Traditional vs. Intelligent retail

The following data outlines the hard financial shift in operational efficiency across top-tier fashion retailers who have replaced gut-feeling management with AI-driven logic.

|

Financial Indicator |

The Old Way (2024) |

The Intelligent Way (2026) |

Performance Gain |

|

Inventory Turnover (Annual) |

4.2x |

7.1x |

+69% |

|

Cost to Acquire a Customer |

$48.00 |

$31.50 |

-34% |

|

In-Store Sales Conversion |

18.50% |

31.20% |

+68% |

|

Profit Lost to Markdowns |

22% |

9% |

-59% |

|

Product Return Rate (Fit Related) |

30% |

12% |

-60% |

Using the shop floor to win the e-commerce war

One of the most profound shifts in 2026 is the blurring line between the showroom and the delivery hub, defining the true essence of phygital retail. Retailers are now leveraging their physical shops as "Micro-Fulfillment Centers" or "Dark Stores" during off-peak hours. AI algorithms determine which stores have the specific surplus inventory to fulfill online orders for the surrounding neighborhood, drastically reducing shipping costs and delivery times. A flagship store on the main street is no longer just a display case; it is a high-speed node in a delivery network. This integration allows for "Hyper-Speed Local Delivery," where a customer can order online and receive their item from the nearest shop within two hours. This strategy has turned the physical store's high rent from a burden into a massive competitive advantage against online-only giants who lack a local presence.

Real-World Proof: The ‘Tech-Led’ turnaround

The benefits of these tools are being proven daily by industry veterans. A major global sportswear brand recently implemented sensors in its New York flagship to track how customers interacted with a new display. The AI identified that while people were looking at the shoes, they weren't trying them on because the price and technical details were hard to find. The brand adjusted the digital signs in real-time, resulting in a 14% jump in sales that same weekend. In another case, a mid-tier fashion chain used AI to adjust stock between its city and suburban branches. The system recognized a 22% higher demand for work blazers in city centers compared to the suburbs, allowing the brand to move the stock where it was actually wanted before it had to be sold at a discount. This single move saved the company nearly $2 million in just three months.

The Outlook: A new playbook for the C-Suite

For the leadership team, the mandate for 2026 has shifted from simple cost-cutting to a total digital overhaul. CEOs are no longer debating whether this technology works; they are restructuring their entire companies around it. The strategic focus is now on systems capable of making autonomous decisions in the supply chain without waiting for a committee. Chief Operating Officers are breaking down the walls between their "Online" and "In-Store" departments, creating one single team that shares the same data and goals. The focus is squarely on "Margin Recovery"—using technology to stop the waste caused by high returns and unnecessary sales. Leaders are now being judged not just on total sales, but on how much profit they can squeeze out of every square foot of shop floor through smart phygital optimization.

Editor Concludes: Putting the soul back in the sale

The fashion industry has always been about the "New," but for years, its business model was dangerously out of date. The 2026 Pivot proves that the physical store is not a relic; it is an asset that has been rediscovered through the lens of science. By leveraging AI to handle the boring parts; counting stock, predicting demand, and managing delivery, retailers have finally freed their staff to do what they do best: talk to people and help them look their best. The winner in this new era isn't the brand with the most complex computer code, but the one that uses that code to make the physical act of shopping feel personal again. We are witnessing a phygital renaissance where the precision of the computer meets the personal touch of the shopkeeper. The store of the future is not a place where machines replace people, but a place where machines make people more successful.

The global apparel sector is navigating a volatile transition as the traditional digital storefront loses its dominance to third-party conversational interfaces and a revived physical retail landscape. Industry forecasts for 2026 indicate, over 50 per cent of consumers now initiate and complete textile purchases through external applications rather than brand-owned websites. This fragmentation of the buyer journey necessitates a sophisticated approach to Product Information Management (PIM). According to Romain Fouache, CEO, Akeneo, the accuracy and transparency of material specifications have become a brand’s primary competitive advantage in a market where shoppers may never interact with a primary website.

Navigating the AI trust deficit in apparel

Despite the rapid deployment of automated retail tools, the textile industry faces a significant hurdle in consumer confidence. Recent research reveals, only 27 per cent of shoppers who utilized AI-enhanced checkout experiences expressed an intent to repeat the process. This ‘trust phase’ requires manufacturers and retailers to move beyond speculative AI investments, which currently include over 1,300 high-value startups, and focus on practical utility. For the apparel sector, this means leveraging technology to provide granular details on fabric composition, sizing accuracy, and supply chain ethics, as 2025 holiday data confirms that consumer trust is the only sustainable driver of high-value textile sales.

Strategic reversion to physical showrooms

A notable counter-trend in 2026 is the robust return to brick-and-mortar environments, particularly among Gen Z demographics. This resurgence serves as a corrective measure against the high return rates plaguing online-only textile ventures, where products frequently fail to meet physical expectations. By integrating enriched product data within physical stores, formerly digital-native brands are stabilizing their margins and reducing the logistical burden of returns. As the infrastructure of ‘circular shopping’ matures, the successful textile brands of 2026 are those ensuring that every digital data point - whether on ChatGPT or a store shelf—reflects a consistent and verifiable product reality.

Akeneo is a global leader in Product Experience (PX) and product information management, serving major apparel and textile manufacturers across Europe and North America. Originally established in France to solve complex data silos, the firm is currently executing a 2026 growth strategy focused on AI-driven data enrichment. With a strong financial position supported by recent venture rounds, Akeneo continues to scale its platform to help retailers synchronize diverse product catalogs across global, multi-channel ecosystems.

North India’s cotton yarn hubs are witnessing a decisive pricing shift as spinning mills struggle to absorb a 3 per cent M-o-M rise in raw cotton costs. In Ludhiana, mills have implemented price hikes of approximately Rs 2–Rs 5 per kg to maintain viability, though downstream demand from garment manufacturers remains cautious. While the benchmark 30-count combed yarn has seen firmer asking rates, the Delhi market remains largely static, reflecting a disconnect between surging input costs and sluggish retail offtake.

Production realities and margin compression

The domestic spinning sector is grappling with a projected 1.7 per cent decline in cotton output for the 2026 season, which is expected to reach a decadal low of 29.2 million bales. Spinning margins are currently under significant pressure as the cost-to-yarn spread narrows to approximately Rs 96–Rs 100 per kg, notes a senior analyst at ICRA. Despite these headwinds, larger mills are prioritizing export markets to China and Bangladesh to offset weak local demand, which has been dampened by recent 50 per cent US tariff impositions on Indian apparel exports.

Panipat’s recycled ecosystem and oversupply hurdles

Global hub for circular textiles, Panipat presents a polarized landscape. While recycled cotton yarn prices have firmed due to the scarcity of textile waste imports from Bangladesh, the recycled Polyester-Cotton (PC) segment is battling chronic oversupply. Analysts observe, that high-tech recycled fibers are gaining traction in the home textiles sector, yet the abundance of coarse-count PC yarn has prevented price parity with virgin cotton. The sector’s future increasingly hinges on ‘digital passports’ for fiber tracking, ensuring that Panipat’s Rs 60,000 crore turnover can withstand evolving global sustainability mandates.

Ludhiana and Panipat serve as India's primary centers for knitwear and recycled home textiles, respectively. These markets specialize in high-volume cotton spinning and sustainable PC blends for global retail chains. With a 2026 growth strategy focused on automated spinning and circular fashion, the region is adapting to a 1.7 per cent domestic cotton shortfall through increased U.S. imports.