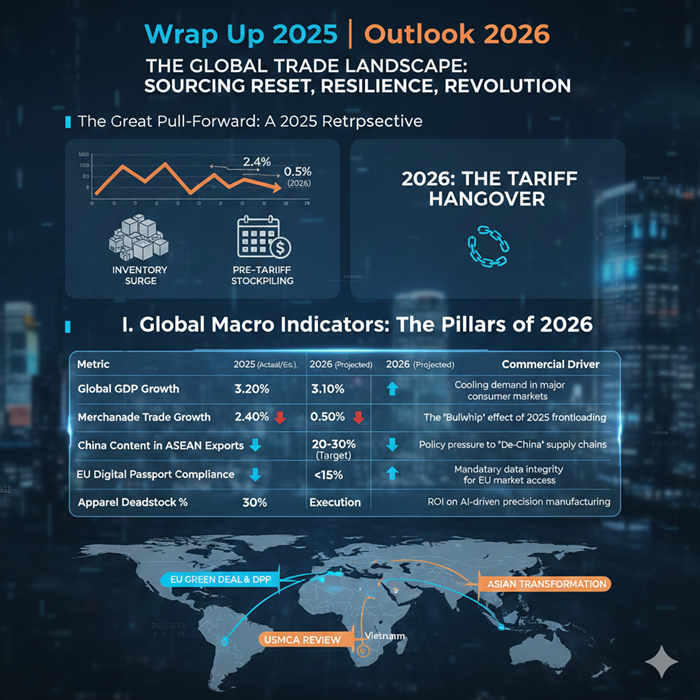

This feature is part of our dedicated series, "Wrap Up 2025 | Outlook 2026," investigating the structural shifts defining the next era of garment commerce.

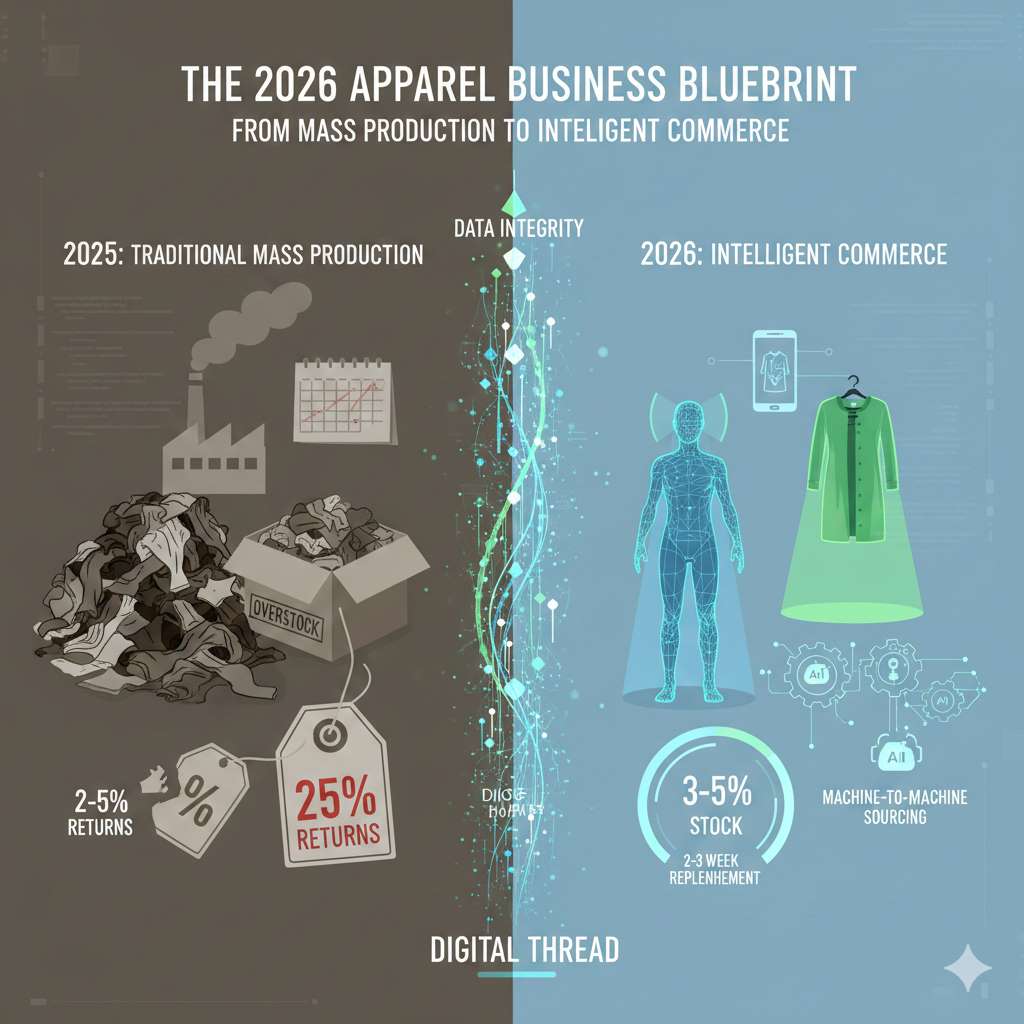

The transition from 2025 into 2026 marks the end of the "trial era" for digital tools in the textile world. For decades, the industry operated on guesswork, over-ordering, and massive end-of-season markdowns. As we enter 2026, the narrative has shifted toward a total integration of technology into the core business of making and selling clothes. We are moving away from traditional "Just-in-Time" manufacturing toward a model defined by Intelligent Commerce. This is a landscape where Artificial Intelligence is no longer a futuristic concept but the primary operating system for sourcing, planning, and manufacturing.

Fixing the Inventory Leak: The move to "Just-Tight-Enough" stock

The most significant financial drain on the apparel industry has always been the self-inflicted wound of over-production. In 2025, the standard practice for most retailers was to order 20% more stock than needed to buffer against shipping delays or sudden spikes in demand. This "Just-in-Case" mentality led to the $60 billion returns crisis and deep margin cuts. However, the 2026 "Inventory Manifesto" focuses on a shift toward Just-Tight-Enough stock levels.

By using AI to analyze real-time sales data and social trends, leaders are now adopting Micro-Batching. Instead of committing to massive production runs months in advance, brands are holding back 70% of their production capacity and only scaling the "winning" products in rapid 2-to-3-week replenishment cycles. This protects cash flow and ensures that capital is never locked in products that will eventually end up in a landfill.

Table 1: The New Economics of Inventory (2025 vs. 2026)

|

Performance Metric |

2025 Traditional Model |

2026 Intelligent Model |

|

Inventory Buffer |

15–20% (Over-stocking) |

3–5% (Precision Stock) |

|

Replenishment Speed |

8–12 Weeks |

2–3 Weeks |

|

Average Return Rate |

25% (Standard Sizing) |

8% (Made-for-Me Scaling) |

|

Deadstock Liquidation |

12% of Total Volume |

Under 4% of Total Volume |

Scaling Custom Clothes: The $65 bn "Made-for-Me" market

One of the most visible changes in 2026 is the industrialization of custom-fit clothing. In the past, "made-to-measure" was a slow, expensive service for luxury buyers. Today, technology has turned it into a $65 billion powerhouse. This shift is driven by the marriage of 3D body scanning and automated pattern-cutting. When a customer scans themselves using a smartphone, that data is sent directly to the factory floor.

The Industrialization of Fit: How 3D scanning and automated cutting scaled from "Made-to-Measure" to "Made-for-Me"

In the past, "made-to-measure" was a slow, manual process reserved for the luxury elite, requiring multiple in-person fittings and weeks of lead time. Today, 2026 has transformed custom apparel into a $65 billion powerhouse by moving personalization from the tailor’s table to the automated assembly line. This shift is driven by the marriage of 3D body scanning and automated pattern-cutting (APC).

The slow, error-prone tape measure has been replaced by smartphone LiDAR scans and in-store 3D booths that capture 100,000 data points in seconds. This digital avatar is then instantly synced with AI-driven pattern-making software. Instead of a human grader manually adjusting a "Size Large" template (the old "Made-to-Measure" way), the AI generates a unique, one-off cutting marker designed specifically for the customer's unique proportions—a true "Made-for-Me" model. This marker is sent directly to laser-cutting machines that slice fabric with sub-millimeter precision. By industrializing what was once a craft, factories in global hubs can now process "lot-size-one" orders with the speed of mass production, finally solving the $60 billion returns crisis by ensuring the garment fits perfectly before the first cut is even made.

The New Way of Buying and Sourcing, Agentic Commerce: When machines talk to factories

The B2B sourcing landscape is undergoing a radical change as we move into 2026. The traditional method of "relationship-based" sourcing—where buyers and suppliers spent months negotiating over catalogs—is being replaced by Agentic Commerce. Major retailers like Zara and Walmart are now deploying AI Agents that act as autonomous buyers. These digital agents "talk" directly to factory ERP systems to check fabric availability, machine capacity, and even real-time shipping costs.

In this new environment, if a supplier's digital system cannot communicate via high-speed APIs, that supplier becomes invisible to the world’s largest buyers. The industry is moving from "who you know" to "how clean is your data." This shift is so profound that legal experts expect 2026 to see the first landmark "AI-sues-Supplier" lawsuit, likely centered on a factory feeding misleading capacity or sustainability data into a retailer's autonomous procurement system.

Table 2: The 2026 Apparel Tech Pulse – Sectoral growth & operational data

|

Sector / Technology |

2025 Adoption Level |

2026 Market Impact |

Primary Value Driver |

|

|

Custom Apparel (POD) |

$48 Billion |

$65 Billion |

Scalable Personalization & Zero Deadstock |

|

|

AI in Fashion (Overall) |

$2.92 Billion |

$3.99 Billion |

40% CAGR; Design to Retail Integration |

|

|

Technical Embroidery |

12% Adoption |

42% Growth |

Smart Fabrics & Integrated Biometrics |

|

|

Machine-to-Machine (M2M) |

Experimental |

20% of B2B Quotes |

Automated Procurement & Replenishment |

|

|

Active Governance (GRC) |

Compliance-led |

Board-level Risk |

Real-time Supply Chain Ethical Audits |

|

Active Governance: Managing risk in Real-Time

Geopolitical instability and supply chain ethics have become the top risks for apparel boards in 2026. The old model of "passive governance", waiting for a yearly audit report to see if a factory is compliant, is no longer enough. The industry has moved to Active Governance, where digital agents monitor every tier of the supply chain in real-time.

These AI-augmented systems track everything from a factory’s carbon footprint to labor law compliance and local political disruptions. This allows companies to build Operational Resilience by automatically rerouting orders or switching suppliers the moment a risk is detected. For the C-Suite, this means moving away from "managing crises" to "preventing disruptions" through a live, digital view of the entire global network.

C-Suite Outlook: The CEO’s strategy for an autonomous era

As we look toward the rest of 2026, the leadership mandate for the apparel industry is clear: the focus must be on Digital Infrastructure. Strategic leaders are no longer just buying machines; they are investing in the "Integrity of the Thread," which now refers to the data that follows a garment from the cotton field to the consumer's closet.

C-Suite priorities have shifted toward ensuring that all company systems, from design to logistics, are fully interoperable. This requires a massive effort in reskilling the workforce, moving employees away from manual tasks like order chasing and toward managing the AI systems that handle the heavy lifting. The goal for 2026 is to create a business that is "data-fluid," where information moves faster than the fabric itself. This reallocation of capital toward Agentic Commerce is creating a massive market impact, as seen in the jump from experimental M2M pilots to a world where 20% of B2B quotes are generated and processed entirely by machines.

Editor’s Conclusion: The integrity of the ‘Digital Thread’

The takeaway for 2026 is that the apparel business is no longer just about fashion; it is about the precision of information. The "Wrap Up of 2025" has shown us that the old ways of mass-producing and hoping for sales are leading to financial ruin. The "Outlook for 2026" offers a much brighter path for those who embrace Intelligent Commerce.

By using AI to eliminate inventory waste, scaling "Made-for-Me" production to end the returns crisis, and adopting "Active Governance" to protect brand reputation, the industry is becoming leaner and more profitable. However, this progress depends entirely on Data Integrity. In a world where machines are doing the buying and factories are running on autonomous schedules, a single piece of bad data can be more costly than a thousand yards of wasted silk. The digital thread is now the most important part of the garment.