Ludhiana’s apparel manufacturing industry is tilting toward technology and investing in automation, be it knitting or stitching. Manufacturers are aiming to increase productivity, efficiency and reduce labour dependency. Flat knitting (multi-gauge) machines that start from five or six gauges and go up to 14 gauges have the option of jointless knitting. This helps users save money and produce more value-added products. Fleece jacquard machines help in this regard. Brother’s DigiFlex series of machines has received a very good response in Ludhiana. These help monitor workers’ efficiency, factory efficiency, no matter where they are. Sewing machine leader Jack is also getting a good response in Ludhiana for its new and different machines. The technology leader recently launched its automatic placket-making machine for tees which can make 1,200 pieces a day in eight hours and help reduce dependence on labor. The company has also introduced automatic button feeders and pattern sewing machines.

Ludhiana accounts for over 90 per cent of the total winter wear production in the country. Knitwear constitutes around 50 per cent of the domestic apparel market in India. There are around 12,000 units in Ludhiana, a majority of them in the micro, small and medium category who are engaged in the production of winter wear. The winter wear category comprises sweaters, hoodies, sweat shirts, jackets, shawls, cardigans and trousers.

Ludhiana apparel industry investing on high tech solutions

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Dubai emerges as the playground for global fashion

Dubai is fast evolving from a regional shopping hub into the central testing ground for global fashion expansion. The Emirate’s... Read more

AEPC petitions Vice President for urgent intervention amid U.S. trade crisis

In a high-stakes appeal for the survival of India’s garment sector, the Apparel Export Promotion Council (AEPC) has formally approached... Read more

A Sector at Crossroads: Why India’s textile sector needs more than relief in Bud…

As Finance Minister Nirmala Sitharaman prepares to table the Union Budget 2026 on February 1, few sectors are watching the... Read more

From Fibre to Power: China’s total takeover of Bangladesh’s textile inputs resha…

The restructuring of the Bangladesh textile sector, long one of the world’s most influential garment manufacturing ecosystems has moved far... Read more

India: A tale of two supply chains, apparel exports grow while textiles struggle

India’s textile and apparel export performance in the first nine months of FY26 tells a story of quiet tension rather... Read more

CMAI integrates precision sourcing with new digital navigation at 82nd NGF 2026 …

The 82nd National Garment Fair (NGF) is set to transform Mumbai’s Bombay Exhibition Centre into the nerve center of the... Read more

From tariff shocks to AI shopping, lessons from a year of two halves in fashion

As 2025 drew to a close, the global fashion and apparel industry gave a reminder that recovery is rarely uniform.... Read more

Touch vs. Tech: How human expertise outperforms AI in fabric evaluation

In a world increasingly shaped by digital design, virtual sampling and AI-powered trend forecasting engines, the most reliable measure of... Read more

From Shanghai to Paris: China’s GREENEXT Expo 2026 launches as a cross-industry …

Amid an accelerating global shift toward low-carbon economies and systemic industrial change, the official launch of GREENEXT Expo 2026 has... Read more

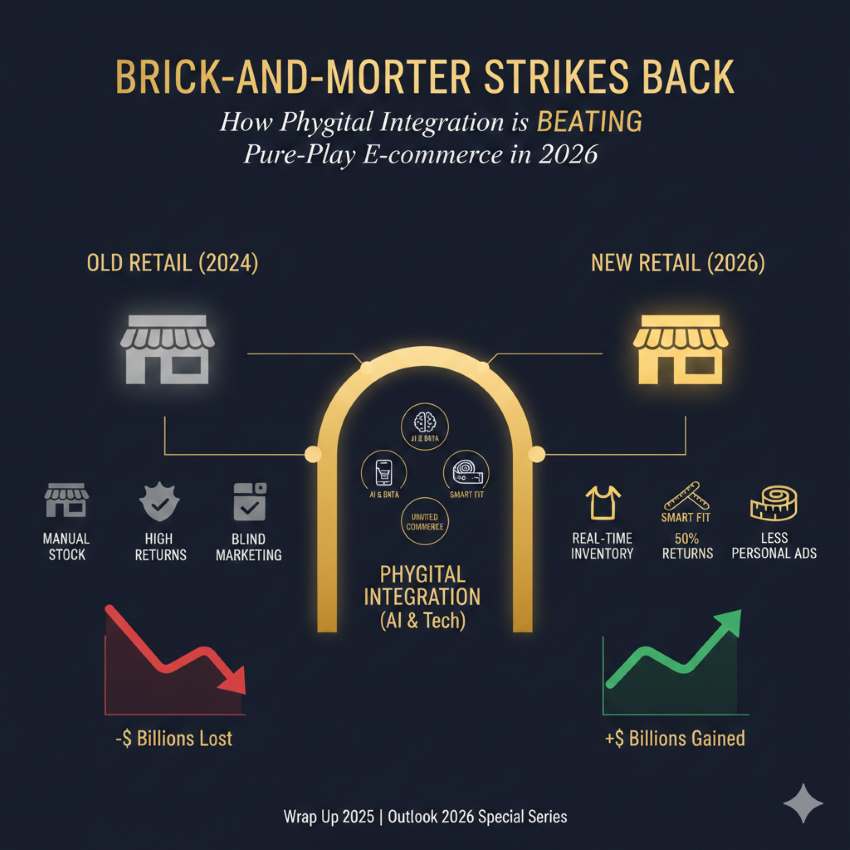

Brick-and-Mortar Strikes Back: How ‘Phygital Integration’ is beating ‘Pure-Play …

This feature marks the final installment of our special series, Wrap Up 2025 | Outlook 2026, exploring the tectonic shifts... Read more