Freudenberg Performance Materials Apparel Europe achieves a significant sustainability milestone with its Sant’Omero, Italy, facility completing the 4sustainability Chemical Management protocol (4s CHEM) at the Advanced Level. The protocol aims to eliminate toxic chemicals and related risks from production processes, aligning with Freudenberg's commitment to environmental and human well-being.

Established as a competence center for interlinings, the Sant’Omero site coats and finishes nonwoven, woven, and weft interlinings for European apparel customers. Taking a proactive approach, Freudenberg enlisted Process Factory, a sustainability consultancy, to implement ZDHC guidelines, leading to the attainment of the Advanced level in the 4s CHEM protocol. This achievement underscores Freudenberg's dedication to meeting stringent sustainability standards in the fashion industry.

By adhering to ZDHC's Roadmap to Zero Program and the ZDHC Manufacturing Restricted Substances List (MRSL), the Apparel Competence Center emphasizes its rejection of harmful chemicals, signaling a strong commitment to environmental stewardship.

Christian Cavaletti, Director of Operations Apparel Europe, affirms Freudenberg's dedication to premium quality and sustainability, stating, "The 4s CHEM implementation proves once again that we not only stand for premium quality but also for products that meet the highest sustainability standards."

Sustainability is ingrained in Freudenberg's corporate ethos, with continuous investments in advanced technologies and the establishment of the Freudenberg Apparel House of Sustainability. This holistic approach defines measures to ensure a sustainable future, with the implementation of the 4s CHEM protocol representing another stride toward this goal at the Sant’Omero facility.

From April 23 to 26, the forefront of textile innovation converges at Techtextil in Frankfurt, Germany, as the Trutzschler Group unveils its latest advancements in nonwoven technology. Positioned at hall 12.0, booth C61, Trutzschler Nonwovens takes center stage, showcasing innovative solutions for the production of premium fiber-based nonwovens.

A focal point of the exhibition is the spotlight on T-Suprema needle-punching lines, representing a leap forward in achieving high-quality fiber-based nonwovens. Emphasizing sustainability, Trutzschler presents eco-friendly solutions for cellulose-based nonwovens, underscoring its commitment to environmentally conscious manufacturing.

Building on the success of Techtextil 2022, which marked the collaboration between Trützschler Nonwovens and Texnology, this year's event sees the inauguration of the T-Suprema needle-punching line at the technical center in Egelsbach, marking a significant milestone in the partnership.

Visitors with an interest in textile recycling are encouraged to explore Trutzschler Spinning's booth, in collaboration with Balkan at booth C68 in hall 12.0. Here, innovative solutions for mechanical recycling and spinning preparation of textile waste are showcased, highlighting Trutzschler's pioneering role in sustainable spinning practices.

At the shared booth with Italian company Texnology S.l.r., attendees can delve into the intricacies of T-Suprema, designed to elevate product quality and system efficiency in premium needle-punched nonwovens. The T-One digital working environment takes center stage, offering insights into sustained high nonwoven quality and process efficiency.

Furthermore, Trutzschler Nonwovens spotlights wet-laid/spunlace (WLS) and carded/pulp (CP) lines for cellulose-based biodegradable wipes, in collaboration with Voith, aiming to drive innovation in eco-friendly nonwoven products.

With a comprehensive range of solutions and services, including high-performance card clothings, Trutzschler reaffirms its commitment to delivering optimum nonwoven quality and process stability, setting new benchmarks in the industry.

In summary, Techtextil 2024 serves as a platform for Trutzschler Group to showcase its pioneering nonwoven solutions, underlining its dedication to innovation, sustainability, and excellence in textile manufacturing.

Fueled by a burgeoning middle class and a growing preference for minimalistic, high-quality goods, Japanese brands are making significant strides in India.

While Japanese cars, watches, and electronics have long enjoyed popularity among affluent Indians due to their craftsmanship, a new wave of mid-range retailers is tapping into this reputation for quality. Currently, around 1,400 Japanese firms operate in India, drawn by the country's vast manufacturing base and favorable foreign investment policies.

Household names like Muji, KAI, and Wacoal have entered the Indian market in recent years, offering everything from fast fashion to kitchenware. With over two-thirds of India's population under 35, brands like Uniqlo are resonating with millennials and Gen Z consumers seeking simplicity and functionality over flashy designs.

A top fashion brand, Uniqlo expanded into India in 2019, quickly opening multiple stores across major cities. Its revenue surged by 69 per cent last year, heating up competition in a market that also includes global giants like H&M.

A key factor behind Uniqlo's popularity in India is its focus on localising products. The brand caters to the tastes of Indian consumers by collaborating with Indian designers and using local materials,

Another Japanese brand that has success through partnerships with Indian companies includes Wacoal which is known for its durable innerwear. The brand entered India in 2015 through a joint venture and has since achieved impressive growth. Renowned for its minimalist aesthetic, Muji partnered with Reliance Brands to open several stores across India.

Japanese retailers have been effective in conveying their distinctive qualities to Indian consumers. For instance, Uniqlo's ‘Arigato Festivals’ during seasonal sales resonate with urban Indians familiar with Japanese culture through media like anime and manga.

Price sensitivity has historically been a challenge for Japanese retailers in India, but experts believe they are focused on building a loyal customer base first before adjusting pricing strategies.

The just concluded Yarn Expo 2024, held in Shanghai from March 6th to 8th, offered a vibrant showcase of latest trends and innovations in the world of fibers and yarns. While cotton remains a mainstay, the focus this year was firmly on sustainable, functional, and high-performance alternatives.

A wave of sustainable solutions

Lenzing Group, a leading sustainable fiber producer, showcased their eco-friendly offerings like Tencel Luxe and Refibra. As per their representative, "Consumers are increasingly demanding sustainable options, and we're seeing a strong shift towards these types of fibers.”

Another key player, Aditya Birla Group, presented their Birla Cellulose Liva Reviva, a nature-based viscose fiber made from recycled materials. Liva Reviva addresses the growing need for responsible fashion," said a company spokesperson.

The trend towards recycled materials was echoed by Patagonia, the outdoor apparel giant who showcased their collection of yarns made from plastic bottles and discarded fishing nets. Ryan Gellert, Patagonia's Director of Materials Innovation underlined their commitment to minimizing environmental footprint throughout the supply chain.

Beyond Cotton: A material menagerie

The expo wasn't just about sustainability. Several participants unveiled exciting new materials pushing the boundaries of yarn technology. Invista, makers of the popular Coolmax fiber, presented their latest advancements in moisture-wicking and temperature regulation technologies. “Our new developments will ensure athletes stay cooler and drier during intense workouts,” said Mike Sanders, Global Product Manager for Performance Yarns.Also on display were specialty yarns by ShanghaiTex who showcased their flame-retardant and anti-bacterial yarns, catering to specific apparel needs.

The ever-growing athleisure market was well-represented, with exhibitors showcasing yarns designed for breathability and comfort during physical activity. Shanghai-based Jinlong Group presented their new line of moisture-wicking polyester yarns, specifically targeted at sportswear manufacturers.

Emerging trends shape apparel design

The Expo also highlighted emerging trends that are shaping the future of apparel design. Liva Regenesis, a new bio-based fiber by Aditya Birla Group, generated significant interest for its soft, cashmere-like feel and biodegradable properties. “Liva Regenesis represents a significant step forward in sustainable luxury,” said Ishan Avachat, COO, Aditya Birla Group’s Cellulose Fibers Business.

Overall, Yarn Expo 2024 provided a glimpse into a future where fabrics are not just beautiful, but also sustainable, functional, and cater to the evolving needs of a conscious consumer. The focus on recycled materials, performance enhancements, and bio-based solutions paves the way for an exciting new era in the world of textiles.

In fact, the Expo provided a concentrated look at the latest developments, other industry events throughout the year are expected to reinforce these trends. The upcoming Première Vision Paris, a leading textile trade show, is likely to showcase how these innovative yarns are being incorporated into finished garments.

With over 800 global visitors and brands, the 35th edition of the Garment Technology Expo (GTE) 2024 met with resounding success. The exhibition was held from Mar 08-11, 2024 at the NSIC Exhibition Complex in Okhla, New Delhi.

Hosted by NSIC Okhla, the expo firmly established itself as the premier garment technology event in Southeast Asia, showcasing the latest innovations and advancements in the garment and textile industry.

Supported by esteemed associations such as the Garment Exports Association of Rajasthan, Gujarat Garment Manufacturers Association, Noida Apparel Export Cluster, and the Association of Apparel Manufacturers and Exporters of Gujarat, GTE 2024 highlighted significant advancements in garment and weaving technologies.

Spanning across 100,000 sq ft of exhibition space, the expo was attended by approximately 20,000 businesses, thus underscoring its significance as a crucial platform for stakeholders in the garment industry.

GTE 2024 showcased displays of innovative technologies and advancements from over 20 countries, enticing visitors with its diverse range of garment manufacturing solutions. The exhibition encompassed all aspects of garment production, including CAD/CAM, sewing machines, fabric washing machines, garment dyeing machines, digital printing, and more.

Ricky Sahni, Joint Managing Director, Garment Technology Expo, hailed the overwhelming support received over the years, emphasising the collaborative efforts contributed to the expo's success.

Ambareesh Chopra, Director Garment Technology Expo highlighted the expo's role in showcasing the latest innovations in the garment industry. The expo provided a platform for major technological brands to showcase their latest offerings and foster industry growth.

The next edition of GTE is scheduled from September 20- 22, 2024 in Bengaluru.

In Q2 of fiscal year 2024, Pakistan's Textile Composite sector witnessed a steep 57.8 per cent Q-o-Q in net profits, falling to Rs5.14 billion compared to Rs12.17 billion in the previous quarter. Textile industry in the country faced significant challenges due to soaring energy costs, leading to a downturn in profitability and partial shutdowns across the sector.

Global economic uncertainties, including rising production costs and frequent energy shortages, further compounded the industry's difficulties.

One major issue affecting the sector is the burden of cross subsidies on energy costs imposed by the regulator. While regional competitors have seen their exports flourish, Pakistan has struggled to increase its exports during fiscal year 2024.

According to Mettis Global's analysis of income statements from four Textile Composite companies, the sector experienced a 7.2 per cent Q-o-Q decrease in sales revenue, amounting to Rs119.3 billion compared to Rs128.6 billion in the previous quarter.

Cost of sales decreased by 5 per cent Q-o-Q but did not proportionally align with the decline in sales, resulting in a 16.7 per cent Q-o-Q decrease in gross profit to Rs 20.4 billion. Selling and distribution expenses decreased by 5.7 per cent Q-o-Q, while other operating expenses dropped by 40.9 per cent. However, administrative expenses rose by 5.5 per cent, reaching Rs 4.1 billion.

During the review quarter, the sector's other income decreased by 50.5 per cent Q-o-Q to Rs3.1 billion, while finance costs increased by 11 per cent to Rs 7.7 billion, primarily due to high borrowing costs. The Export Refinance Facility rate rose to 19 per cent, and the average rate for KIBOR-based financing increased to 22 per cent.

Despite global economic improvements, Pakistan's macroeconomic indicators continue to present challenges, including geopolitical uncertainties and supply chain disruptions.

According to Gul Ahmed Textile Mills, some of these challenges include ongoing conflicts, geopolitical uncertainties, recent hikes in gas prices that have made export sectors less competitive and a shortfall in the domestic cotton crop, that has necessitates the import of cotton bales to meet industry demands.

Adhering to the terms of the IMF's Stand-by Facility, the government has implemented significant hikes in gas prices, leading to a marked increase in the cost of conducting business. These conditions are likely to result in a notable economic deceleration and contraction in export volumes.

L’Catterton’s offer to delist the company led to Italian luxury group Tod's operating profit rising to €94.7 million ($103.3 million) in 2023 from €58.2million a year earlier.

The shoemaker's earnings before interest and taxes (EBIT) surged above the analysts' forecast of €88-million, according to a company-provided consensus.

Its sales rose by 11.9 per cent to €1.13 billion last year, boosted by China and despite slower growth in the last quarter, as per preliminary data released in January.

In the next few years, Tod aims to focus on consolidating its individual brands. L Catterton, the private equity group backed by France's LVMH offered to buy 36 per cent of the Italian luxury shoemaker last month and delist it, in agreement with the Della Valle family which created the company.

Abercrombie & Fitch Co. has decided to venture into the bridal market with a new collection comprising over 100 pieces for brides, bridesmaids, and wedding guests, ranging from $80 to $180.

Recognising the importance of evolving alongside its customer base, Abercrombie sees the bridal collection as a natural extension of its portfolio, targeting individuals in their twenties through forties, particularly those embracing more casual styles for long weekends and special occasions.

Through its entry into the bridal market, Aberchrombie & Fitch aims to cater to a range of wedding-related events from showers to honeymoons. However, the market poses several challenges for the brand including an established presence of competitors who have already carved out their niches. To survive this competition, Abercrombie needs distinguish its bridal line from the rest through innovative design and quality craftsmanship.

Furthermore, shifting wedding trends, such as couples financing their own ceremonies and the decline of traditional bridal retailers like David’s Bridal, have created opportunities for new entrants. The rise of online and affordable options, including those offered by Amazon and other fashion retailers, has intensified competition.

To capture market share, the company must offer unique features and impeccable quality that resonate with brides seeking affordable yet distinctive attire. While investing in design and quality may incur additional costs, it presents an opportunity to attract budget-conscious shoppers looking for value beyond the traditional bridal spectrum.

Despite the overall decline in weddings and changing consumer behaviors, there remains a sizable market segment willing to invest in moderately priced bridal attire. Abercrombie can leverage its expertise in brand revitalization and product quality to establish its presence in this space under the leadership of CEO Fran Horowitz.

In essence, Abercrombie's foray into bridal wear represents a strategic move to diversify its offerings and capture a share of the evolving wedding market. By focusing on differentiation and quality, Abercrombie aims to carve out its niche and build upon its success in redefining its brand image.

As Monforts marks its 140th anniversary, the company remains at the forefront of finishing and coating technologies for technical textiles. Ahead of the Techtextil show in Frankfurt from April 23-26, Monforts anticipates engaging discussions on both existing processes and innovative applications.

Monforts' European-built Montex stenters have established themselves as leaders in fabric finishing within the technical textiles sector. Renowned for their robustness, longevity, versatility, and ecological considerations, these stenters cater to a diverse range of industries including geotextiles, automotive fabrics, and functional materials.

Recent installations highlight Monforts' commitment to serving evolving industry needs. From specialized nonwovens treatment for filter media in Canada to bespoke solutions for sun protection fabrics in France, Monforts' technologies adapt to various production demands.

In Germany, GTA's utilization of wide-width Montex lines underscores the country's prominence in European technical textiles production. Andreas Niess, Managing Director of GTA, praises Monforts' exemplary after-service and quality, affirming their pivotal role in achieving fault-free substrates for digital printing.

Knopf's Sohn, a key player in contract finishing for automotive, aerospace, and home furnishings markets, attests to the efficiency of a newly installed Montex stenter at their facility in Helmbrechts.

Furthermore, Dolinschek, a manufacturer of diverse technical products, relies on Monforts for finishing technology. Their utilization of Montex stenters and Montex Coat coating units underscores Monforts' versatility in meeting varied industry demands.

Looking ahead, Monforts Marketing Manager Nicole Croonenbroek emphasizes the anticipation surrounding Techtextil 2024. The exhibition promises to showcase future advancements in technical fabrics, including Monforts' latest development in advanced coating technologies.

Monforts invites attendees to visit their stand at Techtextil 2024, where they will unveil further details on their latest innovations. As the industry continues to evolve, Monforts remains steadfast in its commitment to driving progress and meeting the ever-changing needs of the technical textiles sector.

In a bid to accelerate the transition to a net positive fashion industry, Global Fashion Agenda (GFA), a non-profit organization, has teamed up with PDS ventures, the innovation and investment arm of PDS Limited, to unveil the Trailblazer Programme. This initiative aims to identify and nurture early-stage innovators in the fashion sector and propel them towards scalable success.

In a bid to accelerate the transition to a net positive fashion industry, Global Fashion Agenda (GFA), a non-profit organization, has teamed up with PDS ventures, the innovation and investment arm of PDS Limited, to unveil the Trailblazer Programme. This initiative aims to identify and nurture early-stage innovators in the fashion sector and propel them towards scalable success.

Investment and support

Central to the Trailblazer Program is the provision of significant financial backing, with PDS Ventures offering a substantial investment of up to $ 200,000 to one standout innovator. This injection of capital is designed to fuel the growth and positive impact of the selected company within the fashion industry. Additionally, the winning innovator will receive invaluable commercial and operational assistance from PDS Group’s Positive Materials, a textile company dedicated to fostering low-impact textile innovation through strategic collaborations with startups, supply chain partners, and brands. Moreover, access to PDS Limited’s expansive global supply chain promises further avenues for growth and scalability.

Open call for innovators

GFA and PDS ventures have issued an open call inviting solution providers tackling diverse challenges across the fashion value chain to participate in the program. An esteemed jury, featuring representatives from GFA, PDS ventures, Massachusetts Institute of Technology (MIT), Ralph Lauren Corporation, Fashion For Good, and H&M Group, will evaluate and shortlist applicants. From this pool, eight promising innovations will be selected as Trailblazers, gaining access to expert feedback and investment pitch training from industry stalwarts and PDS representatives.

Pitching for investment

Following comprehensive preparation, each shortlisted innovator will pitch their solution for potential investment. The ultimate Trailblazer will be unveiled at GFA’s Global Fashion Summit: Copenhagen Edition 2024, a premier international forum for sustainability in fashion. Set to take place on May 22-23 at the Copenhagen Concert Hall, the summit offers a platform for Trailblazers to showcase their businesses and forge vital connections with key industry stakeholders and potential investors.

Aligning with the Summit theme

The Trailblazer Program aligns seamlessly with the theme of the upcoming Global Fashion Summit: ‘Unlocking The Next Level.’ As 2024 marks 15 years since the inaugural summit in 2009, this milestone presents a unique opportunity to reflect on the evolution of the fashion sector and the strides made in sustainability. More crucially, it serves as a call to action, urging stakeholders to identify and address pressing gaps to expedite industry transformation.

Voices of endorsement

Federica Marchionni, CEO of Global Fashion Agenda, emphasizes the critical role of innovation and investment in reshaping the fashion landscape. She stresses the importance of supporting early-stage solutions to drive lasting impact, particularly amid economic challenges. Pallak Seth, Founder and Executive Vice Chairman of PDS Limited, echoes this sentiment, underscoring the urgency of backing climate-first innovators with not only financial resources but also mentorship and guidance.

The collaboration between GFA and PDS ventures through the Trailblazer Program represents a significant stride towards fostering innovation and sustainability within the fashion industry. By providing crucial support and investment to budding entrepreneurs, the initiative aims to catalyze positive change and propel the sector towards a more sustainable future.

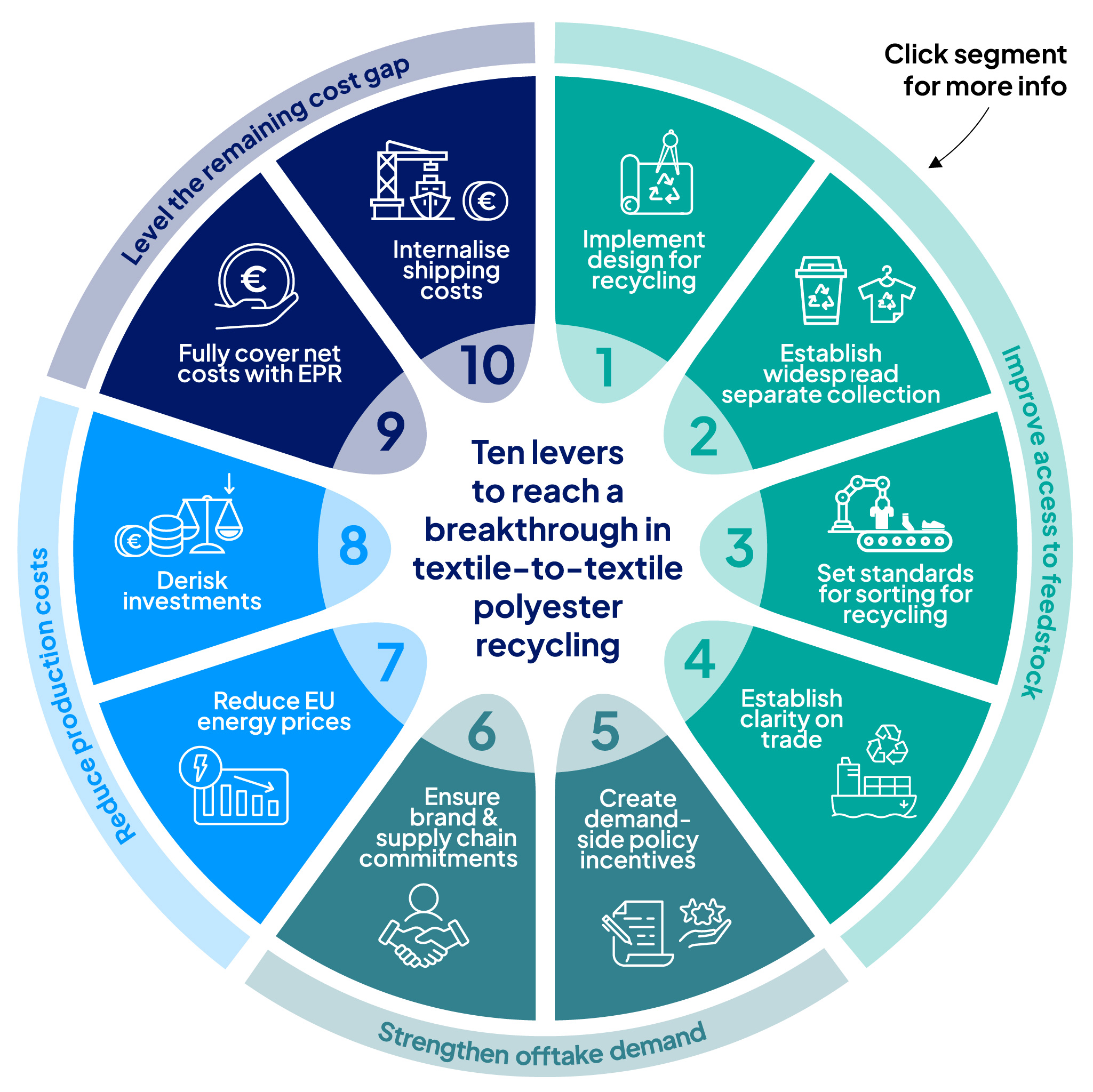

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Europe's Textile Waste Mountain: New report reveals 10-Point plan, sparking deba…

Europe is grappling with a colossal textile waste problem. Over 125 million tonnes of raw materials are devoured by the... Read more

China Weaponizes Subsidies: A strategic play for textile dominance amidst global…

Despite the narrative of a global apparel pivot away from China, the reality on the ground paints a different picture.... Read more

Shift in fashion's value proposition, can speed and sustainability coexist?

Expanding on the recent LinkedIn post by Lubomila Jordanova, CEO & Founder of Plan A and Co-Founder of Greentech Alliance,... Read more

Gartex Texprocess India 2025 kicks off in Mumbai with global focus

The 2025 Mumbai edition of Gartex Texprocess India opened its doors at the Jio World Convention Centre on May 22,... Read more

EU Horizon T-REX project data reveals challenges for textile-to-textile recyclin…

A new report from the EU Horizon T-REX (Textile Recycling Excellence) Project, while focused on piloting a data model to... Read more

Source Fashion to showcase global ethical sourcing solutions in July 2025 editio…

Source Fashion, the UK’s leading responsible sourcing show, is set to return from 8-10 July 2025 at The Grand Hall,... Read more

CHIC September 2025 to return in Shanghai with ‘Fashion Picnic’ theme

China’s leading fashion trade event, CHIC 2025 (September), will return to the National Exhibition and Convention Center in Shanghai from... Read more

US consumer confidence dips amidst economic uncertainty

In April 2025, the US consumer sentiment recorded a shift as confidence levels dipped, indicating potential headwinds for the economy.... Read more

Secondhand on the rise in Europe as it readies for a €26 bn fashion revolution b…

Across Europe, pre-owned garments are shedding their ‘used’ label and stepping into the spotlight as a mainstream force. A new... Read more

India-Bangladesh Trade in Turmoil: Retaliatory measures threaten regional commer…

The burgeoning trade relationship between India and Bangladesh has hit a turbulent patch, marked by a series of retaliatory trade... Read more