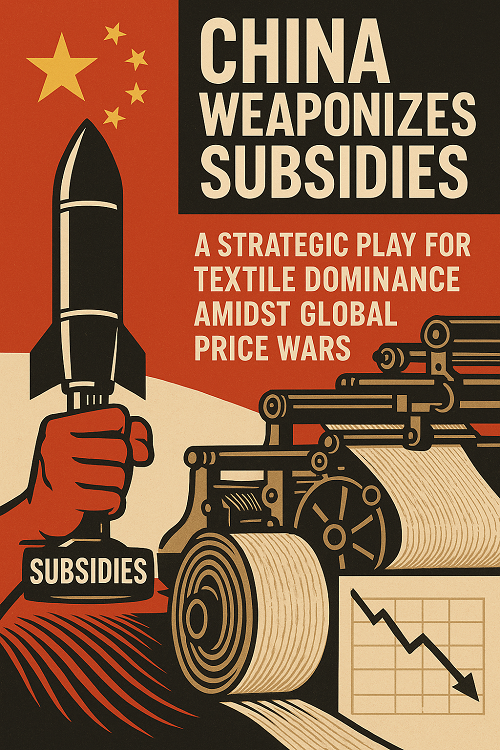

Despite the narrative of a global apparel pivot away from China, the reality on the ground paints a different picture. Far from retreating, China is strategically leveraging a sophisticated web of state support to maintain and even enhance its formidable position in the global textile and apparel industry. This isn't merely about cheap labor; it's a calculated long-term strategy involving substantial financial steroids, upstream supply chain dominance, and a controversial yet integral role for regions like Xinjiang. The underlying goal is clear: to ensure the world continues to play on China's terms.

The Anatomy of Chinese Textile Subsidies: Breaking down the financial steroids

China's textile industry benefits from a multi-faceted approach to state support, effectively creating an environment where domestic producers can consistently undercut global competitors on price. These subsidies are not always direct cash handouts; they often manifest as a complex interplay of financial incentives and preferential policies.

Key forms of subsidies and their impact:

● VAT Export rebates: A significant portion of value-added tax (VAT) paid by Chinese textile manufacturers is rebated upon export. While the exact rebate percentages vary by product and policy, they serve as a substantial cost reduction mechanism for exporters.

● Subsidized energy and utilities: Chinese textile manufacturers often enjoy preferential rates for electricity, water, and other essential utilities. This lowers operational costs significantly, particularly for energy-intensive processes like dyeing and finishing.

● Free or heavily subsidized land: Local governments frequently offer free or extremely low-cost land leases to textile companies, especially in industrial zones designated for development.

● Cash grants and preferential loans: Direct cash grants are provided for technological upgrades, environmental compliance, and capacity expansion. State-owned banks offer preferential loans with lower interest rates and longer repayment periods.

● Infrastructure investment: The government invests heavily in infrastructure, including transportation networks, ports, and logistics hubs, further driving down supply chain costs for Chinese textile producers.

● Tax incentives: Beyond VAT rebates, various tax holidays, reduced corporate income tax rates, and other tax breaks are often extended to textile enterprises.

Case Study: Breaking the pricing inputs

Consider a scenario where a textile manufacturer in Bangladesh is calculating the cost of producing a cotton T-shirt. They must factor in the full market price for raw cotton, energy, land, and standard commercial loan rates. A Chinese competitor, however, benefits from:

● Raw material (Cotton): While China is a major cotton producer, the industry also imports. However, even domestically, cotton production in Xinjiang benefits from significant subsidies, including direct payments to farmers and incentives for cotton planting. This can depress the effective domestic price for mills.

● Energy costs: If the Bangladeshi manufacturer pays $0.12/kWh for electricity, the Chinese manufacturer might pay an effectively subsidized rate of $0.07/kWh. Over high-volume production, this translates into significant savings.

● Land costs: The Bangladeshi firm might incur a significant upfront cost for land acquisition or high rental fees. The Chinese firm might have acquired land for free or at a nominal cost, freeing up capital for other investments.

● Financing: A loan at 8% annual interest for the Bangladeshi firm could be a 3% or 4% loan for the Chinese firm, thanks to state-backed lending.

The table below provides a simplified and estimated breakdown for illustrative purposes.

|

Cost Component |

Estimated Cost for a Non-Chinese Manufacturer (USD/Unit) |

Estimated Cost Reduction/Benefit for a Chinese Manufacturer (USD/Unit) |

Estimated Effective Cost for a Chinese Manufacturer (USD/Unit) |

Explanation of Reduction/Benefit |

|

Raw Material (Cotton) |

0.8 |

-0.10 to -0.20 |

0.60 - 0.70 |

Subsidies for cotton farmers in China, particularly in Xinjiang |

|

Energy Costs (Electricity) |

0.15 |

-0.03 to -0.05 |

0.10 - 0.12 |

Preferential electricity rates,potential subsidies |

|

Land/Factory Rent |

0.1 |

-0.05 to -0.08 |

0.02 - 0.05 |

Free or heavily subsidized land lease, lower rental costs in government-designated industrial zones. |

|

Labor Costs |

0.3 |

(Relatively similar in some regions, but potential indirect benefits) |

0.28 - 0.30 (Note: Not a direct subsidy but part of overall cost structure) |

The overall lower cost of living and social welfare contributions can contribute to slightly lower effective labor costs in some areas. |

|

Financing Costs (Loan Interest) |

0.05 |

-0.01 to -0.02 |

0.03 - 0.04 |

Access to state-backed loans with lower interest rates |

|

VAT Export Rebate |

0.00 (not applicable) |

-0.10 to -0.13 (reduction upon export) |

-0.10 to -0.13 (net benefit) |

Rebate on theVAT paid during production |

|

Other Subsidies/Grants |

0.00 (not applicable) |

-0.02 to -0.05 |

-0.02 to -0.05 (net benefit) |

Direct cash grants for technological upgrades, environmental compliance, R&D, and operating in specific economic zones. |

|

Logistics & Infrastructure |

0.08 |

-0.01 to -0.02 (indirect benefit) |

0.06 - 0.07 |

Ports, transportation partly funded by the state |

|

Estimated Total Cost |

1.53 |

-0.32 to -0.55 (Net Reduction) |

0.98 - 1.21 |

This illustrative table demonstrates reduced/effective production cost for a Chinese textile manufacturer |

These combined advantages allow Chinese manufacturers to offer prices that are simply unsustainable for their global counterparts.

Upstream Dominance: The invisible hand of the supply chain

China's strategic genius extends beyond direct manufacturing subsidies to its formidable control of the upstream textile supply chain. Even if brands try to diversify their apparel production to countries like Vietnam or Bangladesh, they often remain reliant on Chinese-made yarns, fabrics, and specialized components.

This upstream dominance creates a dependency, allowing China to exert continued influence over global textile pricing, even for garments assembled elsewhere.

Xinjiang: A controversial locus of state-funded growth

The role of Xinjiang in China's textile strategy is particularly contentious. Despite international condemnation and bans due to allegations of forced labor, the region remains a cornerstone of China's cotton and textile production.

The U.S. Uyghur Forced Labor Prevention Act (UFLPA) aims to block imports made with forced labor from Xinjiang. However, the pervasive nature of state-supported production in the region, coupled with the difficulty of auditing supply chains in such an environment, makes enforcement challenging.

Data Insights and trends:

We can observe overarching trends and historical patterns that underscore China's strategic approach.

Table 1: China's Textile & Garment Export Performance (Q1 2025 vs. Q1 2024)

|

Category |

Q1 2025 Export Value (Billion USD) |

Q1 2024 Export Value (Billion USD) |

YoY Growth (%) |

|

Total T&G Exports |

66.281 |

65.651 |

+0.95% |

|

Textile Exports |

33.269 |

32 |

+4.0% |

|

Garment Exports |

33.012 (estimated) |

33.651 (estimated) |

-1.90% |

Source: General Administration of Customs, China

This data for early 2025 indicates a slight overall increase in textile and garment exports, driven primarily by textile exports (yarn, fabric, etc.), while garment exports show a slight decline. This further supports the notion of China's focus on upstream dominance.

China's Broader Economic Strategy: Beyond textiles

China's textile strategy is an integral part of its larger economic game plan to maintain global competitiveness. The approach is multifaceted that includes initiatives such as "Made in China 2025" , "Industrial Foundation" and "Manufacturing Powerhouse" initiatives, Focus on Specialised SMEs ("Little Giants"), Export Diversification and Belt and Road Initiative (BRI), Strengthening State-Owned Enterprises (SOEs) and Resilient Cities and Infrastructure Investment

A game of enduring influence

China's strategy to keep its textile industry afloat, and indeed dominant, is a sophisticated and multi-pronged approach that goes far beyond mere competitive pricing. It's a testament to deep state involvement, strategic investment in the entire value chain, and a willingness to leverage controversial regions like Xinjiang for economic gain. While Western nations grapple with tariffs, incentive programs, and human rights concerns, China continues to solidify its position as the undisputed powerhouse of the global textile industry.

The question isn't whether China plays fair, but whether the rest of the world can afford to keep playing by rules that are increasingly skewed.