At the upcoming Techtextil 2024 exhibition in Frankfurt, Germany, the British Textile Machinery Association (BTMA) is set to unveil sophisticated systems for testing fibres and advanced materials. Key exhibitors, including James Heal, VeriVide, Shelton Vision, Airbond, and Fibre Extrusion Technologies (FET), will showcase innovative technologies tailored to meet the evolving demands of various industries.

James Heal, renowned for its longstanding partnerships with major technical textile producers, will spotlight its latest Performance Testing collection, emphasizing simplicity, speed, and intuitiveness in testing procedures. The company's AirPro air permeability tester and HydroView hydrostatic head tester promise enhanced efficiency in assessing textile properties, crucial for applications ranging from medical to outdoor gear.

VeriVide's focus on color precision is evident in its DigiEye system, facilitating non-contact color measurement and digital imaging for streamlined quality control across diverse sectors, including automotive, aerospace, and medical industries.

Shelton Vision introduces WebSpector, an automated fabric inspection system equipped with advanced image processing techniques, capable of flawlessly detecting faults even in fabrics with intricate patterns and distortion.

Airbond's latest splicing technologies offer resource efficiency, particularly beneficial for handling expensive materials like carbon and aramid. With 3D-printed patented splicers, Airbond enables seamless yarn splicing, significantly surpassing traditional machines in handling capacity.

FET's collaboration with clients in developing customized fibres and advanced extrusion systems underscores its commitment to meeting niche market demands. With expanded facilities enhancing capacity and efficiency, FET is well-positioned to accelerate technical trials and drive innovation.

BTMA CEO Jason Kent anticipates fruitful discussions at Techtextil 2024, recognizing the event's significance in shaping the trajectory of the technical textiles market. As BTMA continues to champion British textile machinery on the global stage, Techtextil remains a vital platform for industry leaders to showcase innovations and explore emerging opportunities.

Popular fast fashion giant Shein is a global phenomenon however, it is facing a wave of challenges that threaten its breakneck growth. Indeed, these challenges are a hurdle to its growth but help is in hand in the form of Chinese government which helping it to navigate the challenges.

The road full of challenges

Sustainability concerns: Shein has been criticized for its environmental impact. France is proposing a ban on fast-fashion advertising, potentially including influencer marketing, and fines for companies based on their environmental footprint. The EU's Digital Services Act (DSA) will require Shein to tackle illegal and harmful content, potentially including misleading environmental claims. This is a significant blow as France is a major fashion hub. The legislation aims to curb excessive consumption and highlight the environmental impact of the industry. Shein has been criticized for its use of unsustainable materials and high production volume. This contributes to pollution and textile waste.

Regulation: The aforementioned French proposal and the DSA highlight a growing trend of governments regulating fast fashion. This could increase Shein's compliance costs and limit its marketing strategies. The EU's Digital Services Act (DSA) classifies Shein as a ‘Very Large Online Platform’ subjecting it to stricter content moderation rules. This could impact the way Shein markets its products and potentially limit the spread of misinformation.

De Minimis Exception Scrutiny: The de minimis rule allows parcels under $800 to enter the US duty-free. This rule is being questioned as it allows Shein to offer lower prices, potentially harming American businesses and bypassing regulations. A repeal of the rule could significantly impact Shein's US sales.

Growing competition: Other Chinese e-commerce giants like Temu are competing fiercely with Shein. This competition could put pressure on Shein's pricing and force them to innovate.

Shein and China’s response

While details are limited, Shein might be shifting its focus to transparency and eco-friendly practices to comply with regulations and changing consumer preferences. While there's no official statement on the French ban, but China, a major player in fast fashion, is likely to push back against such regulations. Shein may need to invest in more sustainable practices like using recycled materials or offering repair services. Shein will also need to increase its content moderation efforts to comply with the DSA.

Meanwhile, Chinese government too is doing its bit. China is actively promoting its e-commerce sector globally. This can help Shein and other Chinese brands expand their reach. China may challenge regulations like the French ban or the DSA, arguing they hinder fair trade. China is also revamping its e-commerce infrastructure to maintain fast delivery times despite potential changes to the de minimis rule. Shein's strategic location in South China's garment manufacturing hub helps with this goal. Perhaps what works for Shein is its online-only model and focus on digital platforms that allow for quick decision-making and adaptation to changing regulations and consumer demands.

However, the bottomline is Shein's future success depends on its ability to adapt to a changing landscape. Sustainability efforts, navigating regulations, and potentially adjusting pricing strategies will all be crucial factors. China, meanwhile, is working on streamlining e-commerce logistics to support its fast-fashion giants.

Revising its projections for the current cotton season, the Committee on Cotton Production and Consumption (CCPC) has forecasted a significant rise in production and exports, bolstering optimism in the Indian cotton industry. With a revised estimate of 323.11 lakh bales for the current season, compared to the earlier 316.57 lakh bales, the industry is poised for growth amidst favorable market conditions.

Last season's production has been adjusted downward to 336.60 lakh bales, highlighting the importance of proactive management in response to market dynamics. Despite this adjustment, the CCPC maintains a positive outlook, projecting exports to surge to 27 lakh bales, up from 15.89 lakh bales in the previous season.

The increase in exports comes amid heightened international demand fueled by rising prices on the Intercontinental Exchange (ICE), New York. Indian cotton prices, quoted at Rs 61,500 per candy for the Shankar-6 variety, maintain a competitive edge against ICE May futures, which stand at approximately 93.33 US cents per pound.

With opening stocks projected at 61.16 lakh bales and reduced carryover stocks estimated at 52.27 lakh bales, the industry anticipates stability and growth in the coming months. This reduction in carryover stocks reflects a proactive approach to supply management, aligning with market demands.

The CCPC's projections underscore the industry's resilience and ability to capitalise on favorable international market conditions. With increased production and exports, coupled with competitive pricing strategies, the Indian cotton industry is well-positioned for expansion and revenue generation.

Garments and textiles led Vietnam’s exports of 27 key products to Cambodia during the first two months of this year, shows data from the General Department of Vietnam Customs.

Vietnam exported garments and textiles worth $123 million during the period with exports of textile fibers and footwear totaling $17.9 million. Overall exports of garment, textile, and footwear from Vietnam to Cambodia reached $56 million.

Among ASEAN nations, Cambodia stands as the fifth largest export market for Vietnamese goods, trailing behind Thailand, Indonesia, the Philippines, and Myanmar. Cambodia's share corresponds to 13.6 per cent of the total trade turnover between Vietnam and the ASEAN bloc during the first two months of the year.

Recognising the growing importance of sustainability in the textile and clothing industry, industry events Techtextil and Texprocess plan to focus on this forward-looking theme. A key feature of these events will be the Nature Performance area within the Fibers & Yarns product segment.

This area showcases cutting-edge sustainable materials with impressive functional properties, ranging from bio-based to recycled or degradable options. The development of this area is being driven not only by ecological benefits but also by their performance and profitability.

Sabine Scharrer, Director - Brand Management (Technical Textiles & Textile Processing), Messe Frankfurt, says, the objective of this new program is to create platforms for innovative solutions and facilitate networking among industry players.

Among the exhibitors in the Nature Performance Area will be OceanSafe, a Swiss startup presenting its innovative ‘naNea’ solution. Manuel Schweizer, CEO, explains the superiority of their Cradle to Cradle certified fibers and yarns, which are not only biodegradable but also flame-retardant and hydrophilic, making them attractive across various applications.

Another participant, Vegeto, sees Techtextil as an opportunity to introduce its plant-based thermal insulation made from milkweed fibers to new markets. Ghyslain Bouchard, General Manager, stresses the importance of making performance eco-friendly solutions widely accessible.

In addition to showcasing innovative materials, Techtextil features FranklinTill, a renowned trend and future agency, presenting regenerative design under the title Future Materials. This exhibition offers insights into visionary designers and producers contributing to sustainable practices.

The Nature Performance area is a part of Messe Frankfurt's Econogy program, which aims to consolidate sustainability initiatives across their textile events. The program includes the Econogy Finder, an online directory listing certified sustainable exhibitors, Econogy Talks featuring high-profile discussions, and Econogy Tours led by experts to selected sustainable companies.

To be held from April 23 to 26, 2024, Techtextil and Texprocess aim to provide a crucial platform for promoting sustainability in the textile industry and fostering collaboration among stakeholders committed to eco-friendly solutions.

In a innovative collaboration with Vanguard Pailung, Groz-Beckert unveils a game-changing innovation in knitting machine technology. The introduction of an innovative slider needle marks a significant leap forward in the realm of ultra-high-speed knitting machines for body-sized products. This revolutionary needle technology, unveiled for the first time at the prestigious ITMA event in June 2023, promises to redefine productivity standards in the industry.

The partnership between Groz-Beckert and Vanguard Pailung exemplifies a strategic approach to innovation, with a focus on co-development projects. Leveraging Groz-Beckert's Technology and Development Center (TEZ), both companies collaborated closely to bring this cutting-edge solution to fruition. The result is a new generation of circular knitting machines equipped with the advanced slider needle technology, poised to outperform conventional systems in speed and productivity.

Unlike traditional latch needles, the slide needles operate without a needle latch, utilizing a controlled slide mechanism within its channel. This innovative design enables the needles to withstand high speeds without the hindrance of latch impact, thereby significantly enhancing productivity.

The adoption of slide needles in ultra-high-speed machines ensures unparalleled process reliability. By guiding the closer safely and precisely within the needle shank groove while maintaining maximum stability, the slider needle eliminates the risk of latch impact, guaranteeing a uniform and speed-independent loop structure even at maximum speeds.

The success of this collaborative endeavor can be attributed to transparent communication and shared utilization of data and design specifications from the project's inception. This achievement underscores the transformative potential of industry partnerships in driving innovation and advancing technological frontiers.

Held in early February, the 38th edition of Milano Unica ended on a successful note with international brands expressing their interest in Made-in-Italy fabrics and accessories.

The opening ceremony was graced by Adolfo Urso, Italian Minister of Businesses and Made-in-Italy Manufacturing. During the event, Alessandro Barberis Canonico, Outgoing President, ceremoniously passed the baton to his successor, Simone Canclini.

Simone Canclini, President, Fondazione del Tessile Italiano and CEO, eponymous company established in 1925 in the silk district of Como, is renowned for producing luxury fabrics. For Milano Unica, Canclini produced an excellent product through a seamless continuation of efforts to cultivate growth, particularly within the premium and luxury segments.

During his inaugural address, President Canclini highlighted the two critical factors that contribute to Milano Unica's ongoing success:

The first factor pertains to the exhibitors. Exhibitors at the event represented a diverse array of small, medium, and large enterprises, meticulously selected for their unwavering passion and ability to navigate challenges through innovation.

The second factor revolves around the esteemed visitors, the discerning clients of the industry's finest companies. They attend Milano Unica with confidence, knowing they will encounter collections of exceptional quality.

The central government has announced the extension of the 'Samarth' scheme, a flagship initiative aimed at bolstering capacity building in the textiles sector, for an additional year. The Ministry of Textiles disclosed that the scheme, which was slated to conclude on March 31, 2024, will now continue within the original budget of Rs 390 crore. Approved by the Department of Expenditure under the Ministry of Finance, this decision underscores a dedicated effort to enhance skill development and employment prospects within the textile industry.

Structured as a demand-driven and placement-oriented skilling scheme, Samarth was crafted under the comprehensive skilling policy framework of the Ministry of Skill Development & Entrepreneurship. Its primary goal is to stimulate job creation within the organised textile and related sectors. The scheme encompasses the entire textile value chain, excluding spinning and weaving, and prioritises aligning training programs with dynamic technological and market demands, both domestically and internationally.

Furthermore, the scheme introduces a specialised provision for upskilling and reskilling programs to augment the productivity of existing workers in the apparel and garment segments. This reflects the government's commitment to fostering continuous learning and development in the workforce. Notably, Samarth extends its support to traditional textile sectors such as handloom, handicraft, silk, and jute, addressing their upskilling and reskilling requirements.

Implemented through various partners including textile industry associations, state government agencies, and sectoral organisations of the Ministry of Textiles.

Samarth incorporates advanced features such as a Biometric Attendance System, Training of Trainers, CCTV recording of training sessions, dedicated helpline numbers, mobile apps, Web-based Management Information Systems (MIS), and online monitoring mechanisms. These technological interventions ensure transparency, accountability, and accessibility in the skilling process, making information readily available to stakeholders and the public.

Renowned Swedish furniture giant, IKEA is planning to relocate more of its production operations to Turkey in response to challenges in global supply chains and rising shipping costs. Kerim Nisel, Chief Financial Officer- Turkey, highlights the brand’s intention to manufacture various products locally, such as armchairs, bookcases, wardrobes, and kitchen cabinets, which are currently shipped over long distances from East Asia to markets in the Middle East and Europe.

Nisel emphasises the lessons learned during the COVID-19 pandemic, stressing the importance of diversification in production locations. He underlines the inefficiency of relying solely on manufacturing in one country and then transporting goods worldwide, particularly in light of shipment disruptions experienced during the pandemic.

IKEA already operates seven stores in Turkey and has a robust export business, with exports exceeding imports threefold. The company currently manufactures textile, glass, ceramic, and metal products in Turkey for global distribution.

The decision to shift more production to Turkey aligns with similar moves by other European brands, such as Benetton, which are increasingly decentralising production by expanding manufacturing in regions closer to their main markets.

Turkey's strategic geographic position straddling Europe and the Middle East makes it an attractive location for manufacturing, particularly amid shifts in global supply chains.

However, despite the advantages of Turkey's location and manufacturing capabilities, challenges persist, notably currency fluctuations. It is difficult to hedge against fluctuations in the Turkish lira, particularly with interest rates exceeding 20 per cent, says Nisel. To mitigate currency risks, IKEA employs short-term hedging contracts ranging from 3 to 6 months, he adds.

For the upcoming spring 2024 season, Paradised is expanding into the menswear category. The brand is launching new collection featuring T-shirts, cardigans, sweaters, dress shirts, and trousers, priced between $90 and $500.

Sinje Lesemann, Creative Director, says, she had a longstanding interest in venturing into menswear. A rise in the number of male customers purchasing items from the women’s collection gave the brand an opportunity to explore this avenue further.

The collection stays true to Paradised's resortwear aesthetic, incorporating core design elements from its existing line. Lesemann utilised the brand's distinctive Turkish towel fabric for several pieces, such as the Wylie dress shirt adorned with fringe. Additionally, the brand remains committed to sustainability by offering T-shirts dyed with botanical extracts, all of which are crafted in Brooklyn.

Drawing inspiration from workwear, Lesemann introduced structured trousers made from faded gauze fabric. By incorporating workwear influences into its signs but imbuing them with its signature faded gauze, the brand blends functionality and style suitable for both resort and city settings.

Since rebranding from Koza to Paradised in 2018, the brand has experienced steady growth. Lesemann attributes some of this success to strategic collaborations during the COVID-19 pandemic, including partnerships with SoulCycle and Bandier. Looking ahead, the brand is preparing to launch a home collection.

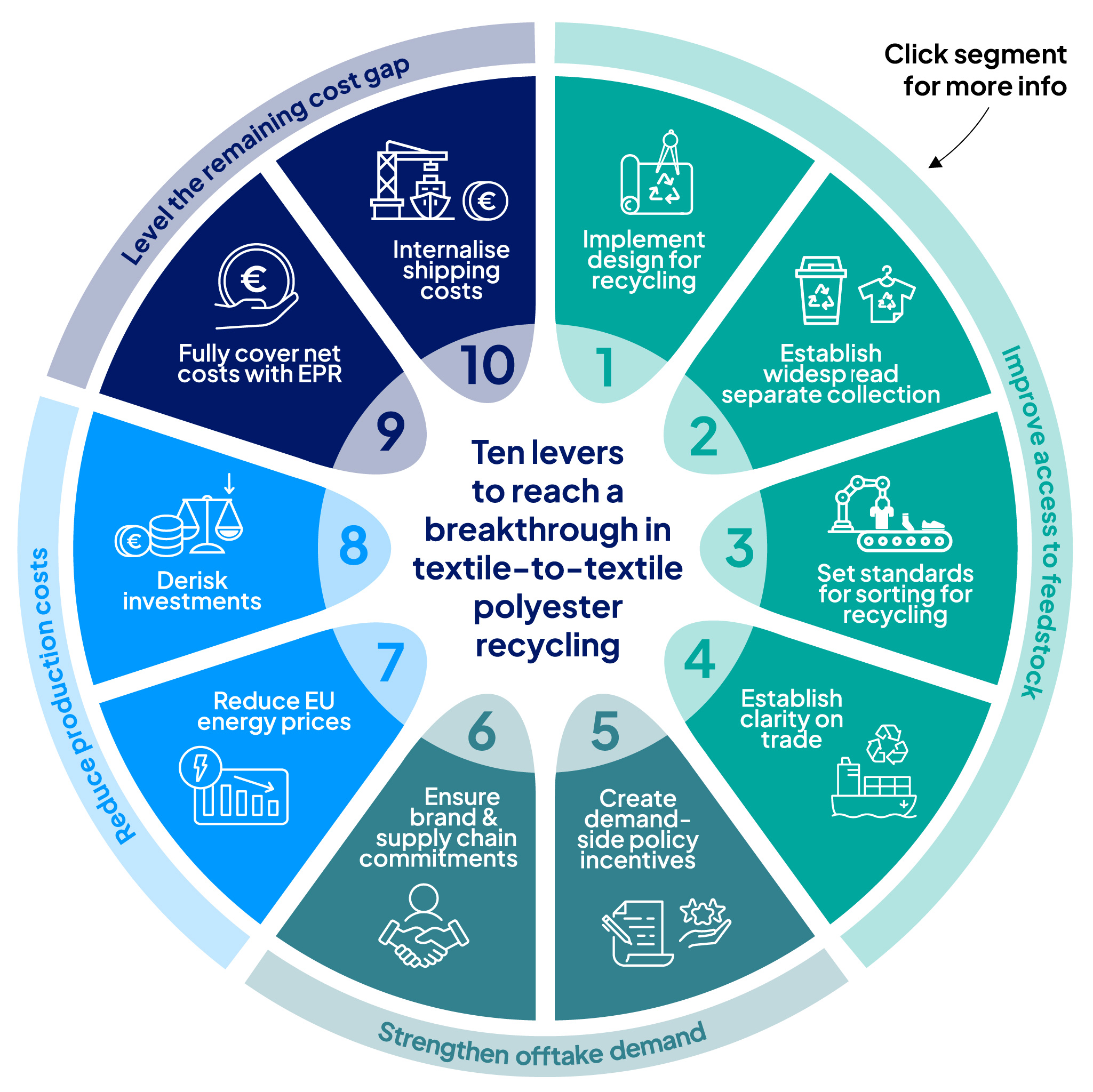

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Europe's Textile Waste Mountain: New report reveals 10-Point plan, sparking deba…

Europe is grappling with a colossal textile waste problem. Over 125 million tonnes of raw materials are devoured by the... Read more

China Weaponizes Subsidies: A strategic play for textile dominance amidst global…

Despite the narrative of a global apparel pivot away from China, the reality on the ground paints a different picture.... Read more

Shift in fashion's value proposition, can speed and sustainability coexist?

Expanding on the recent LinkedIn post by Lubomila Jordanova, CEO & Founder of Plan A and Co-Founder of Greentech Alliance,... Read more

Gartex Texprocess India 2025 kicks off in Mumbai with global focus

The 2025 Mumbai edition of Gartex Texprocess India opened its doors at the Jio World Convention Centre on May 22,... Read more

EU Horizon T-REX project data reveals challenges for textile-to-textile recyclin…

A new report from the EU Horizon T-REX (Textile Recycling Excellence) Project, while focused on piloting a data model to... Read more

Source Fashion to showcase global ethical sourcing solutions in July 2025 editio…

Source Fashion, the UK’s leading responsible sourcing show, is set to return from 8-10 July 2025 at The Grand Hall,... Read more

CHIC September 2025 to return in Shanghai with ‘Fashion Picnic’ theme

China’s leading fashion trade event, CHIC 2025 (September), will return to the National Exhibition and Convention Center in Shanghai from... Read more

US consumer confidence dips amidst economic uncertainty

In April 2025, the US consumer sentiment recorded a shift as confidence levels dipped, indicating potential headwinds for the economy.... Read more

Secondhand on the rise in Europe as it readies for a €26 bn fashion revolution b…

Across Europe, pre-owned garments are shedding their ‘used’ label and stepping into the spotlight as a mainstream force. A new... Read more

India-Bangladesh Trade in Turmoil: Retaliatory measures threaten regional commer…

The burgeoning trade relationship between India and Bangladesh has hit a turbulent patch, marked by a series of retaliatory trade... Read more