A new collaborated study by YCP Solidiance and Brother Machinery Asia highlights the importance of digital transformation in the global apparel manufacturing sector. It states, the transformation must start from the beginning in some cases with the setting up of factory machinery. The study charts the course towards an efficient, digitalised supply chain in the industry.

A new collaborated study by YCP Solidiance and Brother Machinery Asia highlights the importance of digital transformation in the global apparel manufacturing sector. It states, the transformation must start from the beginning in some cases with the setting up of factory machinery. The study charts the course towards an efficient, digitalised supply chain in the industry.

Importance of digitalization

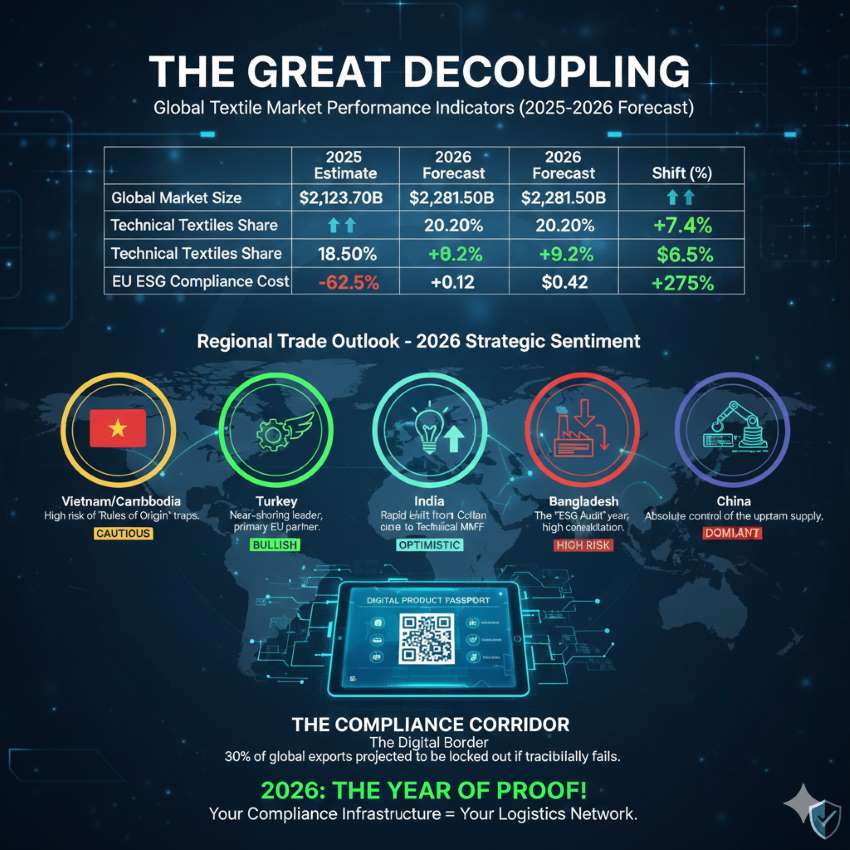

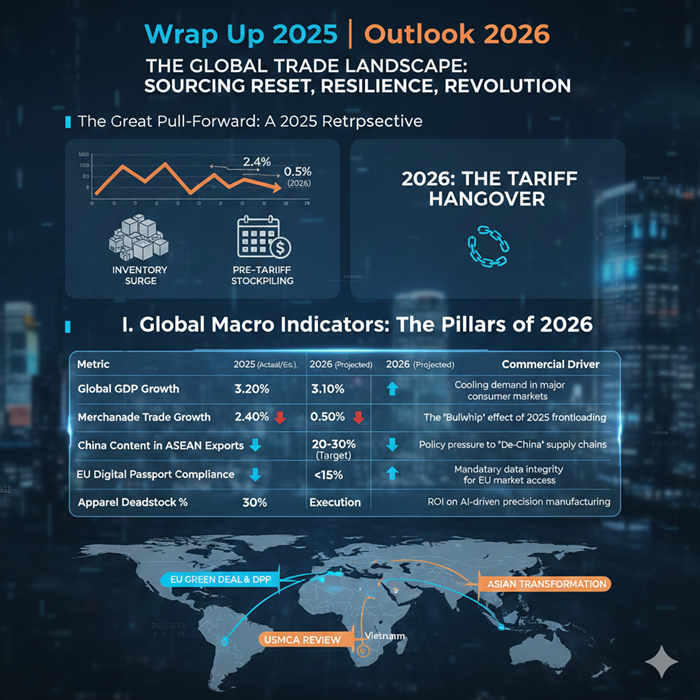

The study mainly focuses on the Asia Pacific region -- the hub of global apparel manufacturing -- with key players like China, India, Bangladesh, Vietnam who have emerged as the sourcing centres for top apparel brands. China in fact, is the apparel manufacturing leader “with expertise, experience, modern infrastructure, efficient supply chain management and high productivity.” India on the other hand has come up as a strong competitor. Vietnam and Indonesia are emerging with their governments focusing on the segment. Sri Lanka, Pakistan, Bangladesh offer even cheaper alternatives.

The study states, these markets together hold the giant share of global apparel manufacturing industry worth $9.5 billion. With strong CAGR of around 5 per cent since 2016, the sector is expected to be worth $10 billion in 2021.

per cent since 2016, the sector is expected to be worth $10 billion in 2021.

However, even though the numbers indicate growth, a closer look throws up an industry in crisis. “Low labour costs that make Asian markets so dominant in apparel manufacturing are rapidly on the rise – in China particularly and across ASEAN markets. At a more fundamental level, the sector remains primitive from a technology perspective, riddling it with inefficiency and subjecting it to all manner of risks,” says the study.

While factories are still labour-intensive, supply chains are fragmented this, at a time when efficiency at lower costs is being given precedence everywhere. Hence, the way forward is ‘digital transformation’. As Satoshi Kuriga, Partner, YCP Solidiance points out with business strategies becoming tougher and the high-cost of Asian labour markets, digitization is perhaps the only long term solution. He says, implementing advanced technology, such as integrated IoT systems, has increased apparel production by 5 per cent and cut cost and time by 88 per cent.

What’s more, the pandemic has made the situation worse with lockdowns across Asia, the apparel industry lost over 70 per cent of its functions and “decreased the total sewing machine operating hours in Bangladesh, India, Indonesia, and Vietnam to 27 per cent.” Therefore, digital transformation is the immediate necessity for factories in the region reflected in the marked increase in digital investments. The study states, with many starting their digital journey from scratch, a step-by-step approach will unfold.

Way forward with digitization

Digitization should begin with a few steps. First is to set up the hardware to automate basic functions in the production process. The hardware then needs to be backed up with advanced robotic and artificial intelligence technology, to efficiently coordinate the machines through data and training. Step three is to integrate the hardware and software function and implement Internet of Things (IoT) technology.

“Once these steps are complete, manufacturers can move on to the final stage of coordinating the entire supply chain ecosystem – from sourcing to retail – using technology such as blockchain to transparently record and monitor information as well as AI and data analytics to make the process more efficient.”

All this will add up to a digitized supply chain that improves efficiency and productivity, while minimising both costs and risks. “Such a setup would be a gold standard for fashion brands, and the race is on.”And with many brands wanting to move away from China in a post-pandemic market to mitigate risks will be looking at safer alternatives. And other countries in the region investing in digital transformation can fill this gap.