FW

On December 13, 2025, Bottega Veneta officially inaugurated its new 3,358-sq-ft boutique at 58 Gansevoort Street, signaling a decisive shift in Manhattan’s luxury retail geography. Strategic proximity to New York’s fashion-forward cluster defines this expansion, as the Italian house joins prestigious neighbors like Hermès, Gucci, and Loro Piana in the Meatpacking District. This move reflects a broader trend identified in the 2025 JLL Luxury Retail Report, which noted a 65.1 per cent growth in new luxury square footage in New York during the first half of the year, with prime street-level locations commanding asking rents as high as $550 per sq ft.

Amidst a challenging climate for global conglomerates, Bottega Veneta remains a resilient outlier in Kering’s financial portfolio. While parent group Kering faced a 16 per cent revenue decline in H1 2025, Bottega Veneta emerged as a ‘rare bright spot,’ delivering a 3 per cent increase in comparable retail sales and double-digit growth in the North American market. "The house continues to assert its unique positioning through craftsmanship and retail exclusivity, even as the wider sector navigates structural headwinds," stated a Kering executive during the Q3 earnings call. As a case study in experiential and sustainable luxury, the Gansevoort boutique eschews traditional digital marketing in favor of a curated in-store library and the ‘Certificate of Craft’ program, which offers lifetime repairs. By prioritizing longevity and artistic dialogue over logo-centric trends, the brand successfully targets a discerning consumer base that is increasingly immune to ‘luxury fatigue.’

A premier Italian luxury house specializing in leather goods, ready-to-wear, and accessories. Bottega Veneta was founded in 1966 in Vicenza. The brand is the pioneer of the ‘When your own initials are enough’ philosophy, centered on its iconic Intrecciato leather-weaving technique. The house operates as a core subsidiary of the French group Kering, which acquired the brand in 2001.

While the ‘Made in Sweden’ tag has long been synonymous with sustainability, 2025 has brought a sharp realignment in consumer priorities. A landmark December 2025 study from the University of Gothenburg, involving over 1,700 respondents, reveals that Swedes now prioritize health safety and labor ethics over broad environmental claims. Consumers are increasingly wary of the ‘toxic’ side of fast fashion, specifically targeting the elimination of hazardous chemicals in textiles as their primary concern.

The sustainability paradox: Willingness to pay hits a ceiling

The data highlights a significant ‘green premium’ cap in the Swedish market. While shoppers are willing to pay an additional 60–85 SEK ($5.50–$8.00) per garment to avoid the ‘worst-in-class’ production standards - such as poor working conditions or high chemical risks- their appetite for paying extra for ‘best-in-class’ sustainability remains low. This shift suggests that Swedish consumers increasingly view basic sustainability as a non-negotiable regulatory minimum rather than a premium add-on. There is a substantial willingness to pay to reach minimum ethical standards, but very few will fund further improvements, noted Daniel Slunge, Researcjer. University of Gothenburg,

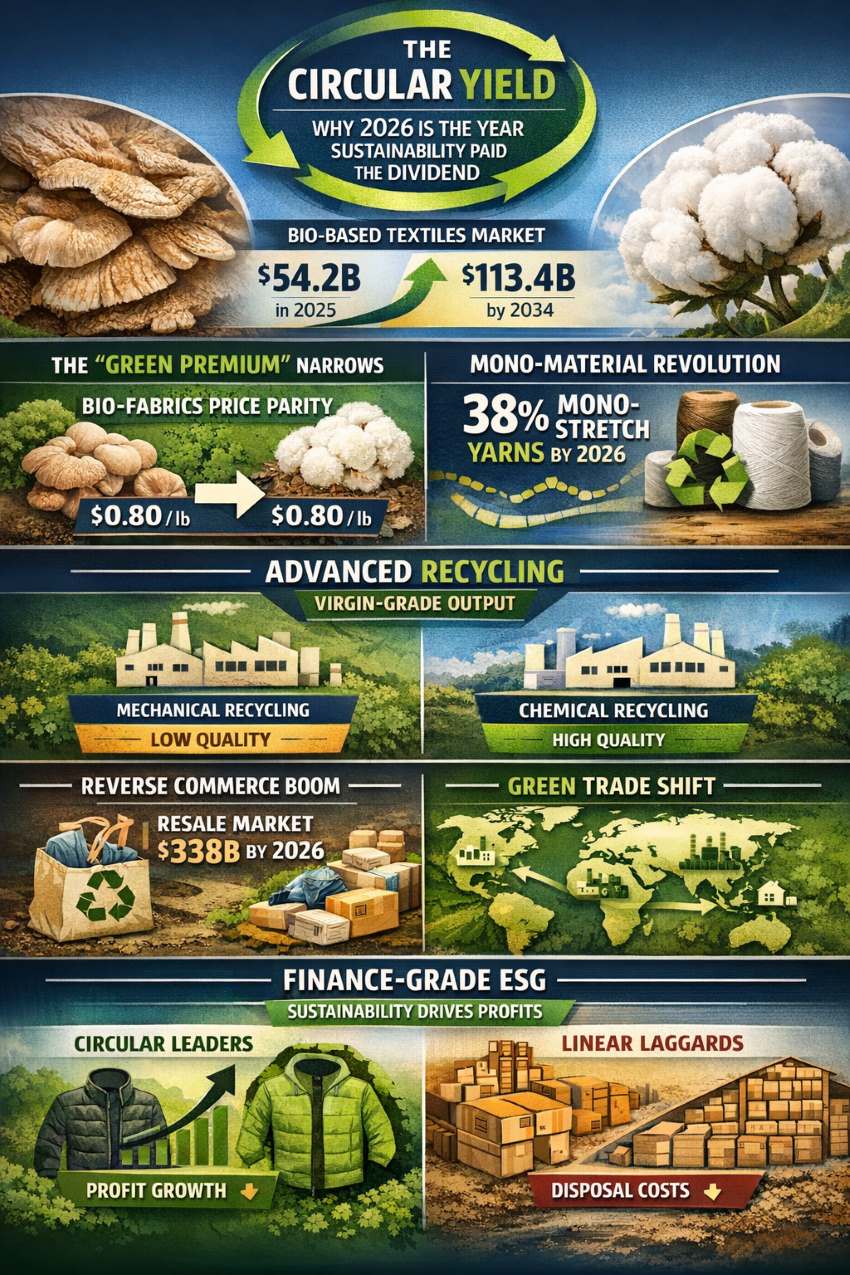

Second-hand and circularity bridge the price gap

As economic pressures persist, the Swedish second-hand market has emerged as the industry's growth engine. In August 2025 alone, fashion resale turnover reached a record SEK 496 million, as consumers hunt for durable, pre-loved items to bypass the high costs of new sustainable apparel. The challenge for 2026 remains infrastructure: while the EU’s new Ecodesign Regulation mandates better traceability, Sweden’s recycling centers are currently overwhelmed, with textile waste collection in Stockholm jumping 60 per cent early this year. Retailers are now under immense pressure to fund the very collection systems they helped fill.

Saks Global enters the final week of 2025 under immense fiscal pressure as it faces a critical $100 million debt payment due on December 30. Despite a high-profile $2.7 billion merger with Neiman Marcus and Bergdorf Goodman exactly one year ago, the conglomerate is now weighing a Chapter 11 bankruptcy filing as a ‘last resort.’ The move highlights a dramatic stumble for the newly formed entity, which was intended to consolidate luxury power but has instead struggled with high-interest debt and severe inventory shortages that dampened Q4 performance.

Inventory crisis fuels market share shift

While Saks grapples with liquidity, rivals Nordstrom and Bloomingdale’s have aggressively captured the displaced luxury spend. Recent data reveals, Nordstrom’s foot traffic grew by 3.3 per cent in early 2025, contrasting sharply with a 6.0 per cent decline for Saks Fifth Avenue. The primary catalyst for this shift has been Saks' ongoing struggle to settle accounts with vendors, many of whom have halted shipments. This lack of fresh merchandise has directly impacted the ‘high-performance, experience-led’ promise of the Saks Global transformation, forcing loyal shoppers to seek available designer collections elsewhere.

Strategic rightsizing amid regional overlap

Analysts suggest, a bankruptcy filing might offer a strategic ‘reset’ button. Currently, nearly 40 per cent of the Saks and Neiman Marcus fleets are located in the same malls or high-street corridors, creating internal cannibalization. A court-supervised restructuring would allow the group to shutter underperforming locations and shed burdensome leases. Opportunities in the luxury market remain strong, and we are exploring all potential paths to secure a stable future, a company spokesperson confirmed. The industry now watches to see if emergency asset sales, such as the rumored 49 per cent stake in Bergdorf Goodman, can provide the 11th-hour liquidity needed to avoid a formal filing.

Luxury menswear landscape has witnessed a significant shift as Middle West Partners (MWP) officially completed its acquisition of Paul Stuart from Mitsui & Co. This transition marks a pivot from five decades of Japanese corporate stewardship to private equity agility. Partnering with North America's largest tailored clothing manufacturer, Peerless Clothing Inc, MWP is signaling an aggressive move to modernize the ‘Ivy League’ aesthetic for a younger, global demographic. By prioritizing a ‘digital-first, heritage-second’ strategy, the new owners aim to bridge the gap between traditional tailoring and the booming luxury lifestyle market.

Strategic modernization and the Asian market opportunity

Under the new leadership of John Hutchison, former CEO, Bonobos and a veteran of modern menswear - Paul Stuart is set to overhaul its retail footprint. The strategy focuses on high-growth regions like India and Southeast Asia, where the demand for ‘quiet luxury’ is surging. The acquisition comes as premium menswear outperforms general apparel, driven by a 12 per cent rise in demand for artisanal, made-to-measure garments. The Paul Stuart name continues to resonate with a discerning client 87 years later, states Kevin Kelleher, Managing Partner, Middle West Partners. The company aims to protect its unmatched quality and amplify its unique attributes on a global scale.

Navigating supply chain resilience and artisanal scaling

A primary challenge for the new owners will be scaling the brand's bespoke quality without compromising its exclusivity. With raw material costs for premium wool and silk rising by 8 per cent Y-o-Y, the group is leveraging Peerless Clothing’s manufacturing expertise to secure supply chain transparency and direct-to-mill partnerships. This acquisition is viewed as a case study in ‘heritage revitalization,’ intended to optimize digital sales channels and reduce reliance on traditional wholesale while capturing a larger share of the $52 billion global luxury menswear sector.

Paul Stuart is a quintessential American luxury clothier renowned for its sophisticated blend of Anglo-American style and superior craftsmanship. The brand specializes in high-end men’s and women’s tailored clothing, furnishings, and footwear, with a heavy emphasis on proprietary fabrics and unique color palettes.

As 2025 draws to a close, the Intercontinental Exchange (ICE) cotton market has witnessed a strategic reversal, with prices rebounding from a multi-week low of 63.1 cents per pound. This late-December surge is primarily driven by aggressive speculative short covering and a depreciating US dollar, which has fallen by 0.3 per cent against major currencies despite robust domestic growth data. By December 24, the most active March 2026 futures settled at 64.24 cents, signaling a cautious but clear shift in sentiment as the textile supply chain prepares for 2026.

Export surge as Asia capitalizes on lower basis

The dip in prices towards the 63-cent mark acted as a ‘buy’ signal for major Asian textile hubs, particularly Vietnam and Bangladesh. US export sales for the week ending December 11 skyrocketed to 304,700 bales, a staggering 99 per cent increase over the previous week. This influx of orders is providing much-needed liquidity to the apparel sector, where manufacturers are balancing rising energy costs against more affordable raw fiber. We are seeing a 'flight to affordability' where cheaper US cotton is being locked in to hedge against projected supply tightness in early 2026, noted a senior analyst at Fibre2Fashion.

Supply constraints loom over 2026 production

While short-term technicals favor the bulls, the broader sector faces a tightening supply outlook. The USDA’s December WASDE report slashed global production estimates by 300,000 bales, bringing the total to 119.79 million bales. Furthermore, certified ICE stocks have dwindled to 11,600 bales, down from over 12,000 earlier in the month. For apparel brands, the challenge in 2026 will be navigating this supply-demand imbalance, as a projected 10-11 million sq ft expansion in retail leasing globally continues to drive the underlying need for finished cotton goods.

Pakistan’s textile industry is bracing for a tectonic shift in its sourcing strategy as domestic cotton production is projected to plummet nearly 46 per cent below official targets. By mid-December 2025, national arrivals at ginning factories reached a stagnant 5.3 million bales, a stark contrast to the Federal Committee on Agriculture’s (FCA) ambitious goal of 10.2 million bales. This supply chasm is forcing stakeholders to forecast a massive import requirement of 7 million bales - a move that ensures factory operationality but threatens to drain over $1.2 billion in foreign exchange reserves.

Climate shocks and policy gaps cripple domestic yields

The precipitous decline is being fueled by a ‘perfect storm’ of climatic and structural failures. While Sindh has surprisingly outpaced Punjab in early arrivals, the national crop has been decimated by climate-induced heatwaves and water shortages during critical planting windows. The repeated issuance of unrealistic national production targets complicates decision-making for exporters who must now lock in more expensive global contracts, notes Kamran Arshad, Chairman, All Pakistan Textile Mills Association (APTMA). Furthermore, the lack of enforcement in crop zoning - where sugar mills continue to encroach upon traditional cotton belts - has systematically eroded the acreage dedicated to the ‘white gold.’

Trade imbalance threatens apparel export competitiveness

While overall T&A exports showed a modest 2.8 per cent growth earlier this fiscal year, the rising import bill for raw materials is compressing margins. The industry is currently battling an 18 per cent sales tax on imported cotton, which, despite being refundable for exporters, has severely constricted liquidity. With November 2025 exports already showing a 2.7 per cent Y-o-Y decline, the sector risks a ‘permanent loss of orders’ as uncompetitive energy tariffs and raw material costs drive global buyers toward regional rivals. The challenge for 2026 will be balancing this import dependency against a fragile trade deficit that has already widened by 16 per cent.

As of December 2025, the Italian fashion landscape is undergoing a massive structural realignment. While the ‘Made in Italy’ label remains a global gold standard for craftsmanship, the sector is currently dominated by strategic mergers and foreign capital inflows as brands seek the scale necessary to survive a volatile luxury market.

The 2025 Christmas season has become a historic window for M&A activity, headlined by the Chinese investment firm HSG’s acquisition of a majority stake in Golden Goose. Supported by Singapore’s Temasek as a minority partner, this move aims to catapult the brand’s presence in Asia while maintaining its Venetian manufacturing roots. Analysts note, this transition marks a broader trend: Italian ‘lifestyle’ luxury is becoming a high-yield target for Asian private equity seeking stable, heritage-backed assets.

Prada and Versace rewrite the high-end playbook

Simultaneously, the domestic landscape has shifted with Prada Group’s integration of Versace, a deal that closed in the final quarter of 2025. This €1.25 billion landmark transaction successfully repatriated one of Italy's most storied houses from American ownership. By appointing Lorenzo Bertelli as Executive Chairman, Versace, Prada is signaling a focus on ‘generational agility,’ leveraging the same digital-first strategies that pushed Miu Miu to record heights this year. The combined group now boasts a formidable turnover of €6.3 billion, creating a domestic powerhouse capable of rivaling French conglomerates LVMH and Kering.

Beyond pure financials, the ‘green’ premium is now a central driver of M&A math. Investors are specifically targeting firms like Usha Yarns and circular-tech innovators who can verify their supply chains. With Italian luxury consumers reportedly willing to pay 64 per cent to 128 per cent more for certified bio-based products, the M&A focus has shifted toward ‘supply chain security.’ The challenge remains ‘slowbalization’- global trade friction that is forcing Italian brands to diversify their manufacturing hubs even as they fiercely protect the artisanal ‘Made in Italy’ credential.

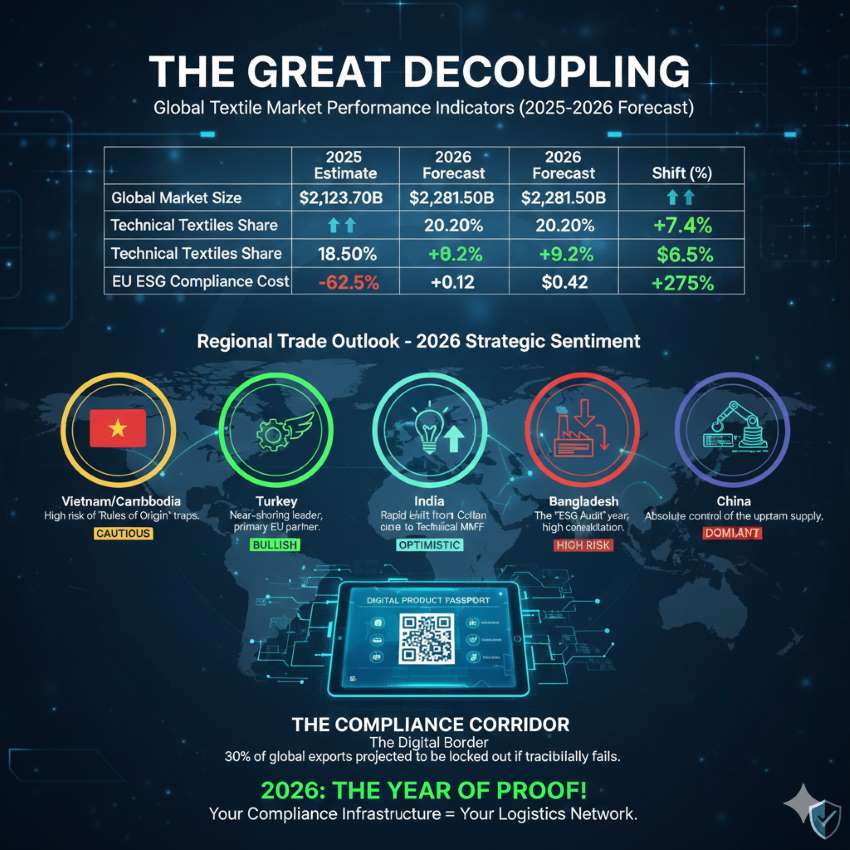

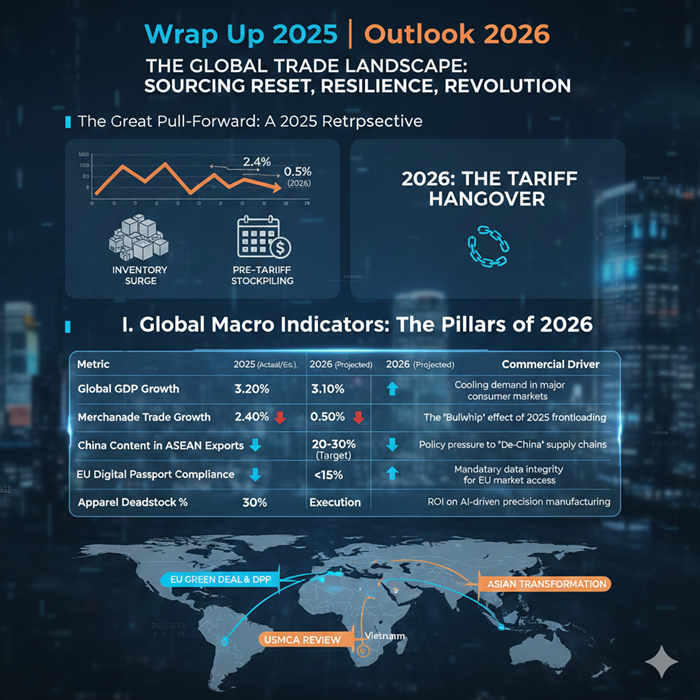

The Great Pull-Forward: A 2025 retrospective

The global textile and apparel industry spent much of 2025 in a state of hyper-vigilance. Driven by a frantic response to geopolitical volatility, importers in North America and the European Union engaged in a massive inventory "pull-forward" to insulate their bottom lines from anticipated 2026 tariff spikes and regulatory shifts. This frantic activity temporarily pushed global merchandise trade growth to a revised 2.4% in late 2025.

However, as the industry enters 2026, it faces a stark "Tariff Hangover." The World Trade Organization (WTO) has sharply downgraded the 2026 trade growth projection to just 0.5%, signaling a period of digestion where the market must work through a massive bullwhip effect of surplus stock.

I. Global Macro Indicators: The pillars of 2026

The macroeconomic backdrop for 2026 is defined by cooling global GDP growth—projected to slow to 3.1%—and a trade environment increasingly dictated by regional blocs rather than global integration. The industry has moved beyond the "China Plus One" era into a complex web of "Regional Resilience," where the winner is not the one with the lowest unit cost, but the one with the highest data integrity and landed cost predictability.

2026 Global Strategic Scorecard

II. Regional Resilience: Rewriting the global sourcing map

The 2026 trade map is being redrawn by the twin forces of protectionism and speed. While North America focuses on the high-stakes USMCA (United States-Mexico-Canada Agreement) review, the first formal six-year assessment since the pact's inception;Europe is tightening its borders through environmental mandates, and Asia is forced to innovate beyond the "China-centric" model.

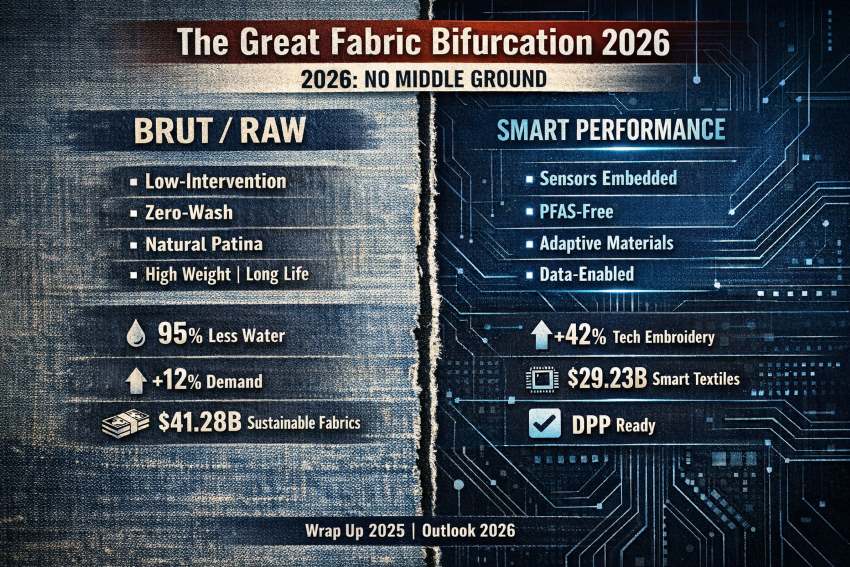

Europe’s Border Control: The green deal and DPP

For the global exporter, the European Union is now a regulatory fortress. The EU Strategy for Sustainable and Circular Textiles and the Digital Product Passport (DPP) have turned data into the industry’s most valuable currency. Any product entering the EU must now carry a digital record of its environmental footprint.

"In 2026, transparency is no longer a marketing claim; it is a license to trade," notes a Brussels-based trade analyst. Suppliers in Turkey and Eastern Europe are leveraging their proximity to meet the EU's "Speed-to-Market" demands, delivering goods to hubs in just 72 hours.

Global trade corridor analysis (Turkey vs. Vietnam)

To understand the 2026 shift, one must look at the divergence between the Turkey-to-EU and Vietnam-to-EU corridors. Under the 2026 regulatory framework, the European Union's Carbon Border Adjustment Mechanism (CBAM) and DPP requirements have created a "compliance tax" on long-haul shipping.

For a standard shipment of denim jeans destined for Rotterdam, the Turkey corridor offers a total lead time of 3 to 7 days via road freight, with a landed cost that benefits from 0% customs duties under the EU-Turkey Customs Union. In contrast, the Vietnam corridor, despite the benefits of the EVFTA, faces a sea-freight lead time of 35 to 40 days. When 2026 ocean carrier emissions surcharges and the mandatory costs of RFID-enabled DPP traceability are factored in, the "unit price" advantage of Southeast Asia is often eroded by the cost of capital tied up in transit. Recent data suggests that near-shoring to Turkey or Morocco now provides 12% landed-cost savings over traditional Asian routes when accounting for these new regulatory and speed-to-market premiums.

The Asian Transformation: Beyond "China-Content"

Asia remains the engine of production, but regulators are increasingly scrutinizing the "China-content" in exports. In response, 2026 sees a massive shift toward vertical integration within Vietnam and India. India is moving into an overdrive of technical textile manufacturing, positioning itself as a high-value alternative to the volume-heavy models of the past. "The goal for 2026 is moving away from being a low-cost needle to becoming a high-tech material partner," says a lead director at the Apparel Export Promotion Council.

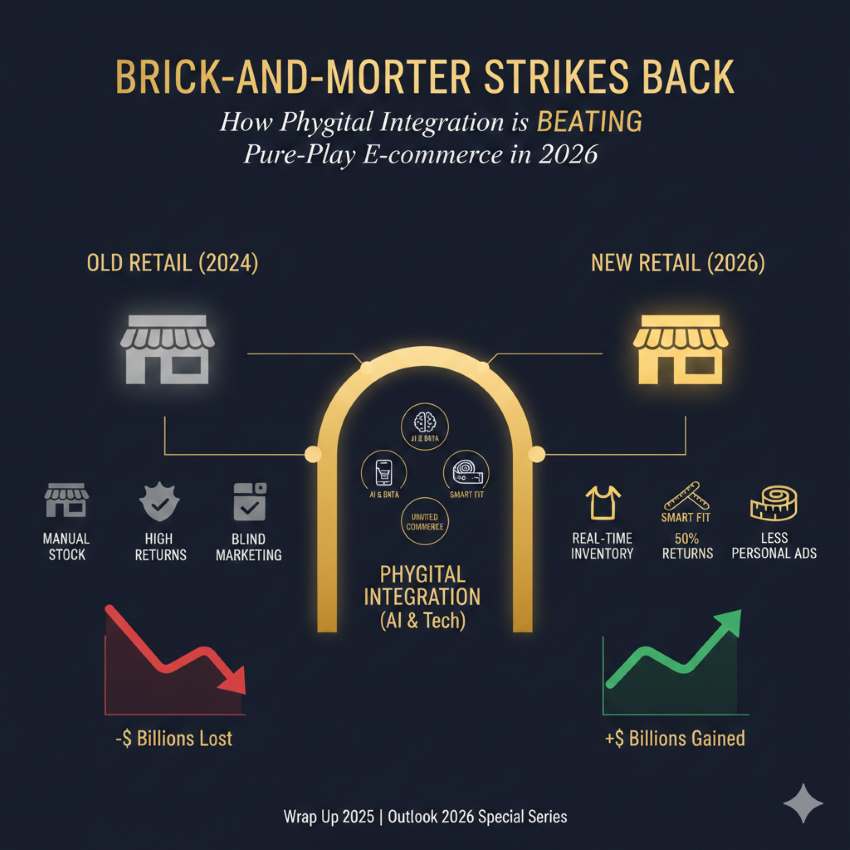

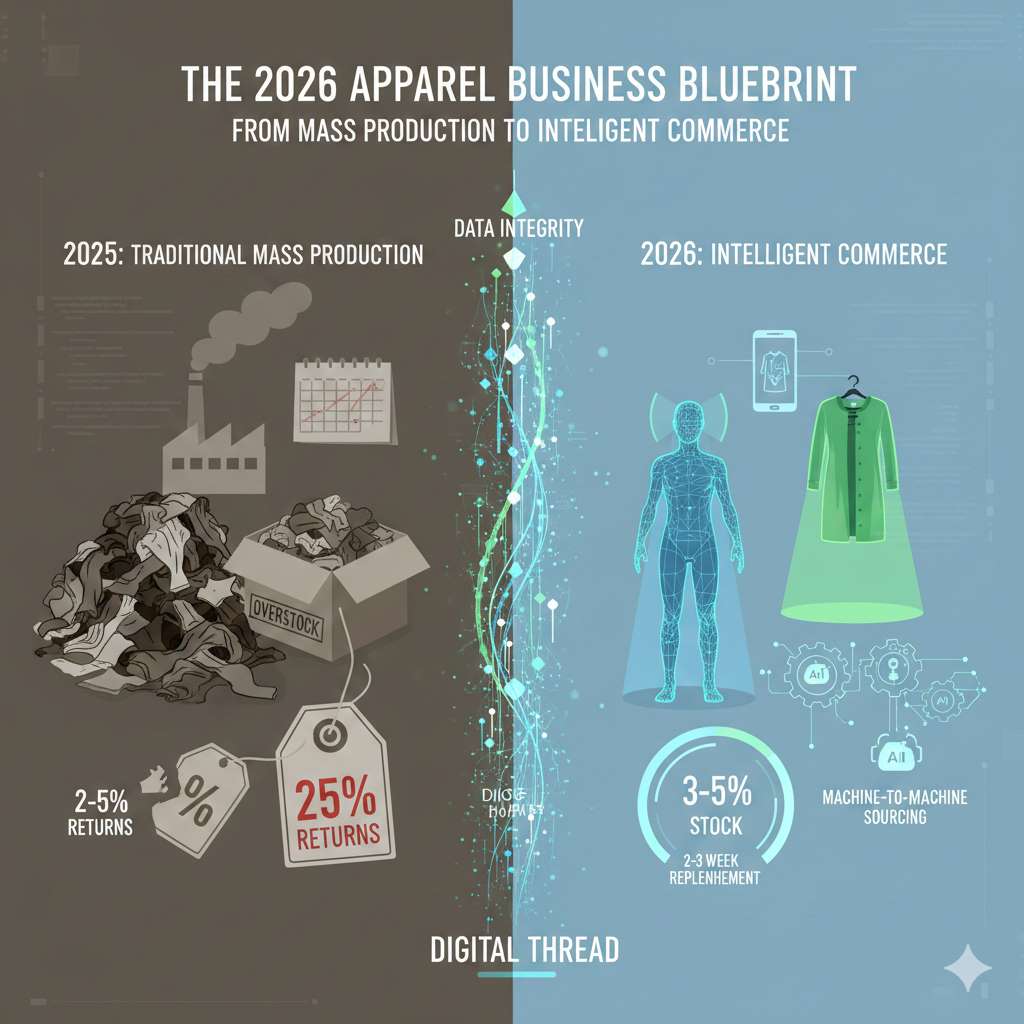

III. The death of the "Just-in-Case" model

The inventory glut of 2025 proved that massive stockpiles are a liability. 2026 marks the definitive end of the "Push" model in favor of "Micro-Batching." Brands are now using AI-driven demand signals to hold production back until a trend is verified, then replenishing winners in weeks rather than months.

The localized "Nano-Factory"

Localized, automated micro-hubs, or Nano-Factories;are now being deployed near major consumption centers. Startups using zero-waste algorithms to turn simple fabric rectangles into high-fashion garments. By reducing the complexity of traditional sewing, they have made local, automated production cost-competitive with offshore labor. This "On-Shoring 2.0" is about building a distributed web of high-tech hubs that can respond to the "Emotion Economy" of the modern consumer.

IV. The C-Suite Outlook: Leadership in the "Poly-Crisis"

For the modern CEO, 2026 demands a shift in identity. The "Poly-Crisis"—characterized by sticky inflation, 3.1% global GDP growth, and shifting trade alliances—requires a leader who is as much a data scientist as a creative director. The "2026 Strategic Scorecard" shows a clear bifurcation: companies that fail to specialize in either "Ultra-Fast/Ultra-Low-Cost" or "Ultra-Transparent/High-Value" are being hollowed out.

The modern CEO must recognize that the industry has hollowed out the middle; there is no longer a safe space for the "undecided" brand. Leadership is now a choice between two distinct commercial identities. On one side, the high-velocity cost leaders are doubling down on logistical efficiency and massive scale to serve a value-conscious public. On the opposite end, high-value specialists are securing their margins through radical transparency, material innovation, and circularity.

This strategic bifurcation is driven by the "Emotion Economy," where brand loyalty is earned through authenticity rather than volume. Executives are moving away from the "Attention Economy" of the 2010s to a "Loyalty Economy" that monetizes brand purpose. "In 2025, we survived the volatility by stockpiling," notes one retail executive, "but in 2026, we will survive by specializing. We are no longer just buying clothes; we are buying certainty and data-backed resilience." This shift is reflected in the massive adoption of AI; by integrating machine learning into demand forecasting, top-performing C-suites have already reported reducing their forecast errors by nearly 40%, directly translating to leaner inventories and protected margins in a stagnant growth environment.

Editor’s Conclusion: The year of verifiable precision

In 2026, a factory’s most valuable asset is no longer its sewing capacity; it is its data infrastructure. Brands are no longer just selling clothes; they are selling "Data Packages" that prove origin, ethics, and circular potential. The "Great Sourcing Reset" is complete. The industry has moved from a world of "Push" to a world of "Respond." For those leaders who have embraced AI-demand forecasting—which early data suggests has already slashed deadstock by 30%—the 2026 outlook is not one of stagnation, but of lean, profitable precision.

For over a decade, Amazon has reigned over American fashion with a formula built on convenience, scale, and aggressive pricing. Today, that era of effortless growth is giving way to a new chapter, one that requires deeper brand-building, high-touch experiences, and a more sophisticated understanding of fashion consumers. Amazon no longer needs to win market share; it needs to win the right kind of share, the profitable pockets of the market where loyalty, curation, and brand equity matter as much as price and delivery speed.

A market leader encounters its next wall

Amazon’s dominance is both massive and measurable. In 2024, the company claimed an estimated 16.2 per cent of all US apparel sales, surpassing Walmart and strengthening its position as the country’s largest clothing retailer. This is reflected clearly in the core table tracking the business.

Table: Amazon US apparel sales, 2024

|

Segment |

Amazon US sales forecast (2024) |

YoY growth rate (category) |

Strategic focus |

|

Clothing, Shoes & Jewelry (Total) |

$79.2 bn |

+12.4% |

Logistics & Volume |

|

Women's Apparel |

$39.6 bn |

+9.0% |

Quality & Private Brands |

|

Luxury Stores |

N/A |

High Priority (Investment) |

Brand Trust & Experience |

The data reveals several important dynamics. The total apparel category, at $79.2 billion, still grows at 12.4 per cent, but this expansion is beginning to trail the broader platform’s growth rate of nearly 20 per cent. In practical terms, Amazon’s apparel business is beginning to mature. The women’s apparel subcategory, generating about $39.6 billion, grows even more slowly at 9 per cent, showing how the basics-driven engine viz. T-shirts, leggings, underwear, loungewear has reached saturation. Meanwhile, the luxury stores segment does not have disclosed revenue but is flagged internally as a high-priority area, indicating Amazon’s shift toward higher-margin zones rather than pure volume.

This is the clearest sign that Amazon’s future in fashion cannot rely on the same levers that led to its rise. It must transition from selling ‘everything for everyone’ to shaping a more curated, brand-forward identity.

The luxury gamble and the battle for brand perception

Amazon’s push into luxury indicates both aspiration and necessity. The company understands that premium shoppers spend more, return less, and create better margins. But it also recognizes that this customer expects something fundamentally different from what Amazon has traditionally offered.

The Luxury Stores at Amazon initiative aims to raise experience introducing controlled online storefronts, high-resolution product visuals, and brand-specific environments that mirror the digital flagships of top-tier designers. Yet the gap Amazon must bridge remains significant. Experts articulate this gap clearly. Ethan Vance, Global Head of Retail Innovation at the Fashion Institute, describes the shaping challenge as “contextualized convenience”, a blend of editorial guidance, emotional storytelling, curation, and style authority layered atop Amazon’s unmatched logistics. The question is not whether Amazon can deliver the goods; it is whether it can deliver the feeling.

Department store incumbents have responded with experiences Amazon cannot easily replicate. Nordstrom’s localized service model, stylist-led personalization, and strong omnichannel integration still resonate with high-intent shoppers. Macy’s continues to emphasize experiential merchandising and physical presence. Amazon’s countermeasures, AI-powered virtual try-ons, fit-recommendation engines, and machine-learning curation are advancing quickly, but they remain digital proxies for in-person engagement.

The luxury focus is thus both a branding challenge and a strategic wager: Amazon must prove it can be a fashion destination rather than simply a fulfillment powerhouse.

Sustainability knot tightening around supply chain

The apparel category is inherently complex, but Amazon’s scale increases the challenges. As the largest seller in the US, the company sits at the center of an industry responsible for 92 million tons of global textile waste annually. With around 65 million US consumers increasingly prioritizing environmentally responsible brands, Amazon finds itself under pressure to modernize every aspect of its supply chain.

The biggest pain point is returns. Apparel return rates are notoriously high compared to other retail categories, and for Amazon, processing a returned garment can cost three to four times more than shipping it out. These are costs that compound rapidly inside a $79 billion fashion engine. The company’s response includes initiatives around circularity, resale, refurbished apparel programs, and improved packaging efficiencies. More importantly, Amazon is investing heavily in AI-driven sizing tools, body data mapping, and design-stage accuracy enhancements to reduce returns before they happen. For a company handling hundreds of millions of fashion units annually, even small efficiency gains translate into major financial and environmental impact.

How the apparel platform actually works

Amazon’s fashion business is not a single monolithic operation. It is a layered marketplace composed of millions of third-party sellers blended with the company’s expanding roster of private labels. Brands like Amazon Essentials and The Drop anchor its mass-market apparel offering, offering seasonless basics and trend-driven capsule collections that consistently rank among its top-selling lines. Its core market remains the US, contributing over $56 billion in clothing, footwear, and accessories sales in recent years. Women’s apparel leads, forming the backbone of the nearly $40 billion that category contributes to 2024’s projected total.

Amazon’s long-term strategy is shaped around three pillars: hyper-personalization powered by artificial intelligence, significant investment in its Luxury Stores venture, and a sweeping redesign of its supply chain to embed sustainability into its cost structure. Each of these pillars is designed to move Amazon from being merely the biggest to being strategically indispensable in fashion’s next decade.

A new era taking shape

When Amazon began its serious push into apparel around 2012, the industry did not view it as a fashion authority. It was a marketplace with logistical advantages, known more for socks and basics than for style. But as the years progressed, the combination of fast shipping, selection depth, competitive pricing, and sheer convenience reshaped consumer behavior and pushed Amazon to become the largest apparel retailer in the US.

Now, as market saturation and consumer expectations evolve, Amazon faces a more complex challenge. The company must demonstrate not only operational excellence but aesthetic credibility, not only scale but storytelling. The brand that conquered basics must now build a new identity one that can speak to value-conscious shoppers and luxury consumers without diluting either experience. Amazon has proven it can dominate. What it must prove now is that it can curate, inspire, and lead.

Myanmar’s garment sector is on track to generate $5 billion in foreign revenue this year. The Chinese Textile and Garment Association in Myanmar (CTGA) warns, a ‘raw material vacuum’ is draining the country’s foreign reserves. Currently, a staggering 95 per cent of factories operate on a restricted Cutting-Making-Packaging (CMP) basis, requiring the costly import of every component from zippers to high-grade fabrics. To counteract this dollar outflow, the industry is aggressively courting Chinese investment to transition toward a high-value Free on Board (FOB) model.

The regional export split and workforce targets

The strategic Free on Board (FOB)95 per cent urgency is backed by a shift in global demand. Recent data confirms, 60 per cent of Myanmar’s garment exports are now absorbed by the European market, followed by 20 per cent to Japan. To sustain this momentum, the Myanmar Garment Manufacturers Association (MGMA) has unveiled a ten-year roadmap (2025–2034) aiming to grow the industry into a $15 billion powerhouse. This expansion is projected to create a massive employment surge, targeting a workforce of 1.2 to 1.6 million people - up from roughly 500,000 today.

Infrastructure barriers and the energy challenge

The transition to FOB is not merely a financial shift but a technical one. At the 2025 Myanmar International Textile and Machinery Fair held in Yangon this month, over 100 exhibitors highlighted that ‘stable energy’ remains the primary hurdle for localized raw material processing.

To mitigate this, Chinese investors are introducing solar-powered textile machinery and advanced generators. Successfully localizing just 20 per cent of input production could stabilize the volatile kyat and transform Myanmar from a simple assembly hub into a vertically integrated apparel giant by 2030.

Representing 523 member factories, MGMA is the primary regulatory and advocacy body for Myanmar's textile, footwear, and apparel sectors. The association oversees the production of knitwear, woven garments, footwear, and accessories, primarily serving high-street European and Japanese retailers.