FW

This report is the eighth installment of the "Wrap Up 2025, Outlook 2026" series, providing a definitive roadmap for the industry’s high-growth categories and regional shifts.

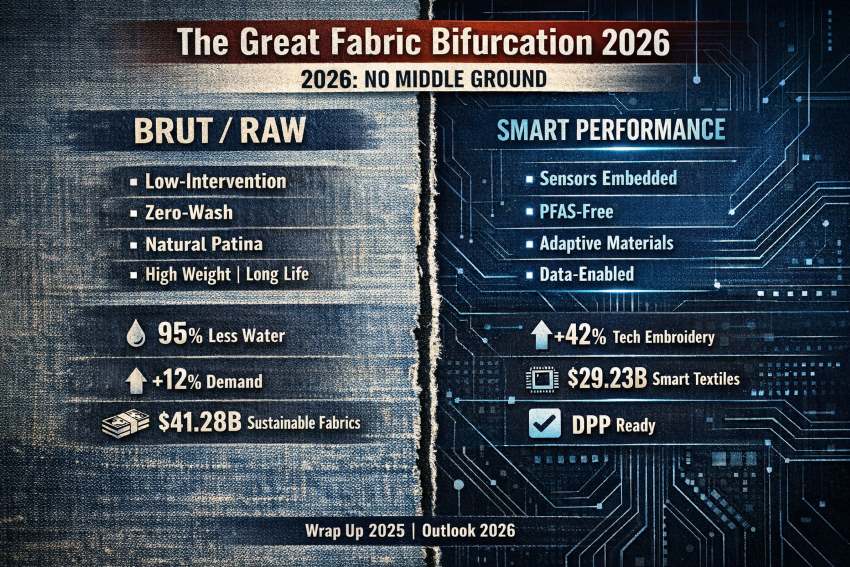

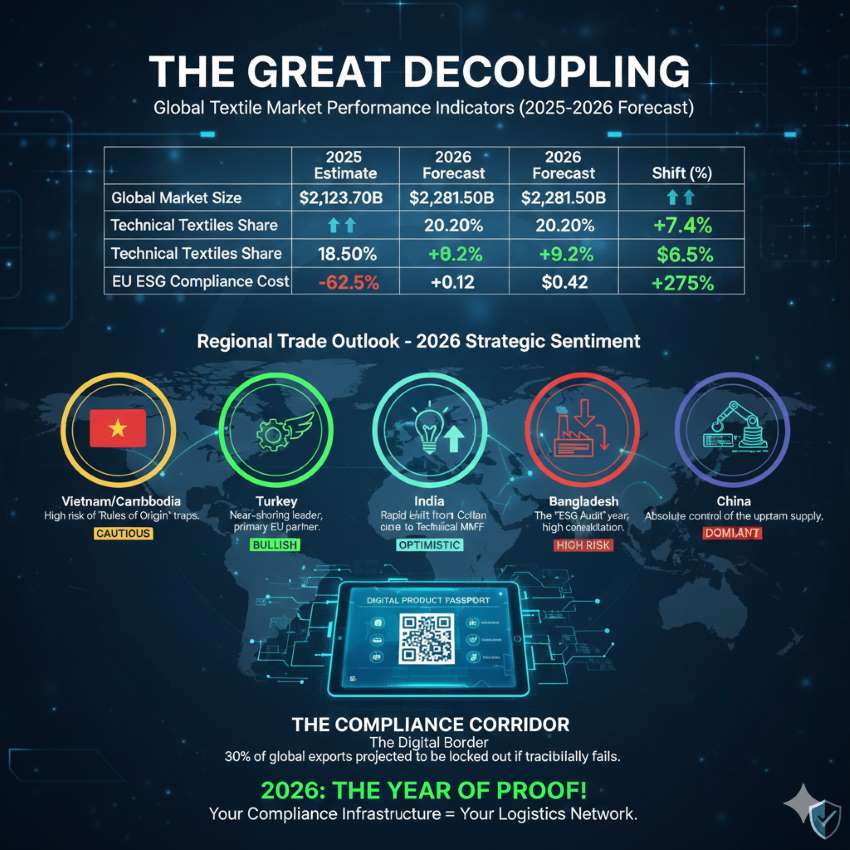

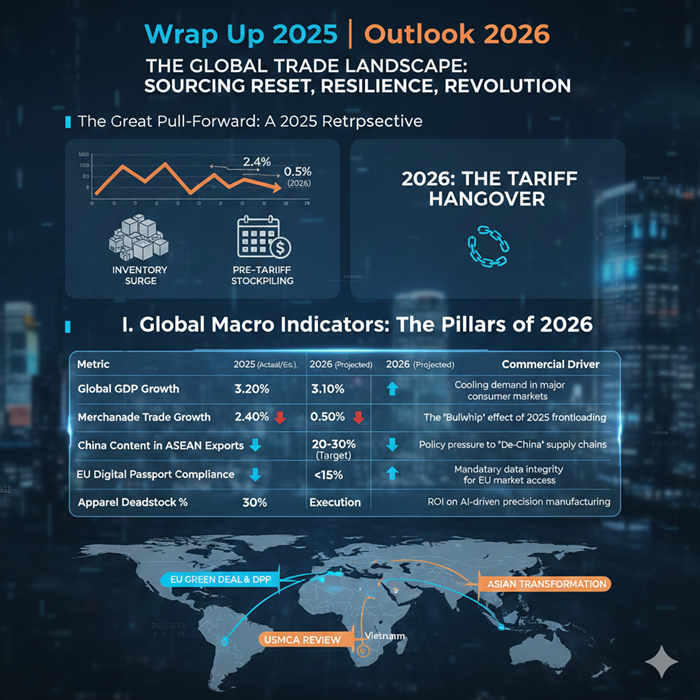

The 2026 global textile landscape is defined by a decisive move away from general-purpose manufacturing toward specialized, high-performance materials. As we move through the year, capital expenditure in the industry is being redirected into the "Double Agenda", fabrics that meet stringent performance requirements while remaining fully compliant with new global trade mandates. The total global textile market is valued at approximately $2,281.51 billion for 2026, maintaining a compound annual growth rate (CAGR) of 7.35%. This growth is increasingly concentrated in segments that offer measurable functional value over basic aesthetics.

2026 sector performance and growth projections

The following data outlines the market valuation and growth trajectories for the dominant industry segments as they stand in the current 2025–2026 cycle.

|

Sector/Segment |

2025 Market Size (Est) |

2026 Projected Size |

CAGR (2025-26) |

Key Growth Catalyst |

|

Apparel (Overall) |

$1.84 Trillion |

$1.91 Trillion |

3.80% |

Casualization & E-commerce |

|

Performance Textiles |

$105.40 Billion |

$113.72 Billion |

7.90% |

Biometric & Smart Sensing |

|

Knits & Sportswear |

$325.40 Billion |

$348.18 Billion |

7.00% |

Tech-Performance Blends |

|

Technical Textiles |

$255.12 Billion |

$271.83 Billion |

6.55% |

Med-Tech & Mobil-Tech |

|

Home Textiles |

$149.09 Billion |

$158.16 Billion |

6.08% |

Smart Bedding & Wellness |

|

Denim Apparel |

$78.90 Billion |

$84.11 Billion |

6.61% |

Waterless Dyeing & Circularity |

|

Bedroom Linen |

$67.09 Billion |

$71.16 Billion |

6.07% |

Functional Finishes |

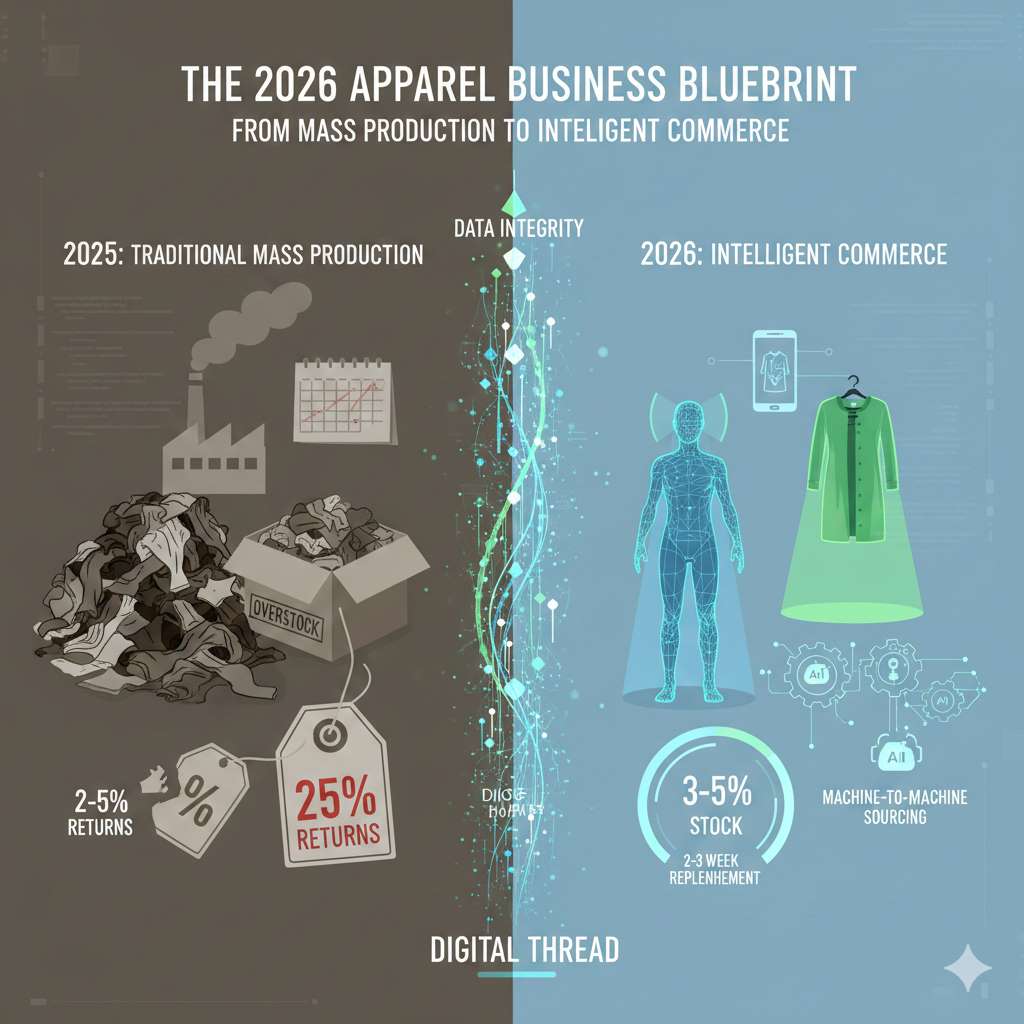

Segment Analysis: Commercial dynamics and strategic stories

Performance Textiles: The "Sensing & Adaptive" suite

Performance textiles have emerged as the fastest-growing niche, projected to reach $113.72 billion in 2026 with an industry-leading 7.9% CAGR. This segment has evolved from simple moisture-wicking gear into "Adaptive Wear", fabrics that use conductive yarns and chromic materials to react to body temperature or environmental shifts. Commercial adoption is being driven by the integration of biometric sensors directly into the fiber matrix, allowing garments to track heart rate and muscle fatigue without external devices. In 2026, the market has split into two distinct tiers: high-end professional "Bio-data" wear and mass-market "Climate-adaptive" apparel that provides breathable insulation in cold weather and active cooling in heat. This segment is a primary winner for North American and Japanese firms, who hold the majority of patents for conductive textile polymers.

Home Textiles: The "Functional Wellness" suite

The home textile sector has transitioned from a decorative category into a health-focused "Functional Wellness" suite. Currently valued at $158.16 billion, the market is being driven by the "Bedroom Linen" sub-segment, which holds a commanding 45% share of the total home textile category. Commercial interest has moved beyond thread counts to "Smart Bedding", fabrics treated with phase-change materials for temperature regulation and silver-ion coatings for antimicrobial protection. These functional finishes are the primary engine behind the 6.08% CAGR, as consumers increasingly view their bedding as a tool for sleep hygiene. From a trade perspective, India has solidified its position as a global leader in this space by combining its massive organic cotton reserves with proprietary technical finishes to satisfy high-end retail demand in the US and EU.

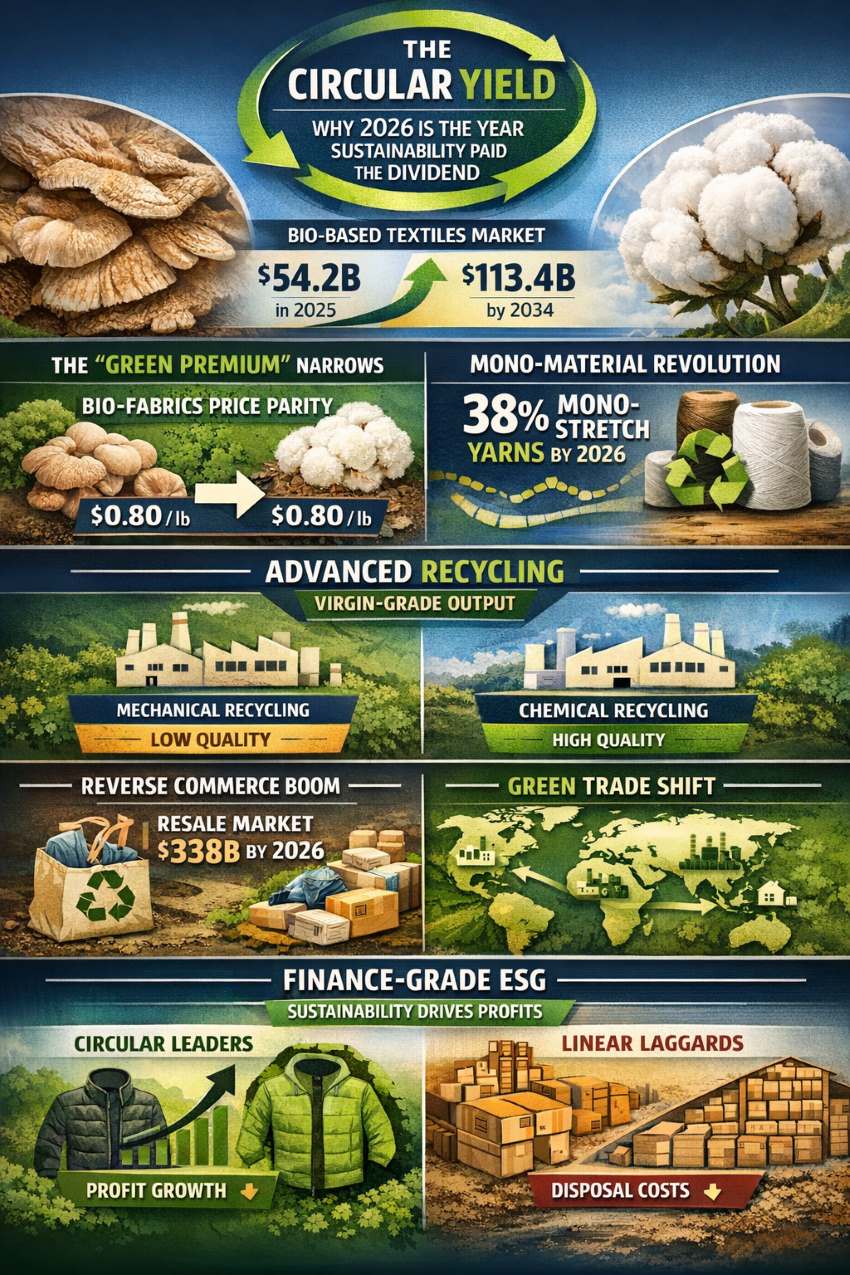

Denim: From advocacy to "Invisible Circularity"

Denim has moved past the era of sustainability "pledges" into an era of rigorous engineering known as "Invisible Circularity." The segment is projected to reach $84.11 billion this year, with a 6.61% CAGR. The commercial goal for 2026 is the production of jeans that maintain a premium, heritage look but are designed for 100% recyclability. Nearly 40% of global manufacturers have now integrated waterless dyeing and laser-finishing technologies to remain compliant with tightening environmental standards in major import markets. The rise of mono-material denim, where even the stitching and hardware are made from shreddable, recyclable polymers;is the current benchmark for market entry. Turkey and India remain the dominant exporters in this high-tech denim race, while Mexico is securing a larger share of the US market through near-shore logistical advantages.

Knits & Sportswear: The "Bio-Performance" frontier

Knits and sportswear represent one of the fastest-growing categories, with a projected size of $348.18 billion and a 7.0% CAGR. The story here is the replacement of petroleum-based polyesters with bio-based synthetics derived from algae and corn. This shift is not just environmental but functional, as these new fibers offer superior moisture-wicking and cooling properties. The adoption of 3D Seamless Knitting has become the industry standard for high-performance brands, as it reduces fabric waste by roughly 30% and significantly lowers labor costs. Vietnam and Bangladesh are the primary winners in this segment, having aggressively upgraded their factory floors with automated knitting systems to capture volume from global athletic giants.

Technical Textiles: The "Industrial Backbone"

Technical textiles are the most resilient pillar of the industry, projected to reach $271.83 billion in 2026. This segment is no longer a niche but an essential industrial component. Growth is heavily concentrated in Med-Tech (implantable textiles and surgical non-wovens) and Mobil-Tech (lightweight, reinforced fabrics for electric vehicle interiors). This is a high-margin sector where intellectual property and patents dictate market power. Consequently, the USA, Japan, and Germany remain the dominant exporters of specialized technical fibers, while China focuses on the high-volume production of industrial filtration and protective gear.

Global Trade Matrix: Winners & Losers (2026 Forecast)

The global trade landscape is being reshaped by regional capabilities in technology and regulatory compliance. Countries that have invested in "green" infrastructure are seeing an influx of foreign direct investment, while those relying on low-cost, high-pollution models are seeing a contraction in orders.

|

Segment |

Regional Winners (Growth) |

Regional Losers (Stagnation) |

Primary Commercial Factor |

|

Performance Textiles |

USA, Japan, South Korea |

China (Standard Synth.) |

Biometric Patent Control & Smart Tech |

|

Home Textiles |

India, Turkey |

China (Volume), Pakistan |

Wellness certifications & Traceability |

|

Denim |

Vietnam, Mexico, Turkey |

USA (Manufacturing), Lesotho |

Near-shore logistics & Waterless tech |

|

Knits/Sportswear |

Bangladesh, Vietnam |

Italy (Mid-tier), Cambodia |

3D-Knitting & ESG Compliance |

|

Technical Textiles |

USA, Japan, Germany |

Rest of Asia (Low-end) |

IP Patents & MedTech Innovation |

Major Exporters and Importers: Leading Dynamics

● India: A major winner in 2026 due to the Production Linked Incentive (PLI) scheme, which has moved the country's export profile from raw cotton to high-value technical textiles and functional home linens.

● China: While remaining the world’s largest exporter by volume, China is losing market share in basic apparel as it moves its manufacturing base toward high-value synthetic fibers and AI-integrated textile machinery.

● Vietnam & Bangladesh: These nations have successfully transitioned from basic cut-and-sew operations to sophisticated, tech-enabled hubs for sportswear and high-end knits, benefiting from strategic free trade agreements.

● USA & EU: As the primary importers, these regions are the "gatekeepers" of the 2026 market. Their demand for supply chain transparency (via the Digital Product Passport) is forcing global exporters to adopt expensive but necessary traceability technologies.

Losers: Countries like Pakistan are facing commercial headwinds due to rising energy costs and a lack of investment in high-tech finishing, while Lesotho and Cambodia are seeing a decline in orders as brands prioritize "Green-ready" hubs that can guarantee lower carbon footprints.

As the fashion industry confronts a staggering 92 million tons of annual waste, the textile recycling sector has transitioned from a niche sustainability effort into a critical commercial pillar. The global market is valued at $6.34 billion in 2025, with projections reaching $9.94 billion by 2033. This growth is increasingly fueled by Extended Producer Responsibility (EPR) mandates across Europe and the US, which effectively end the era of ‘disposable’ inventory by holding brands financially accountable for a garment's entire lifecycle.

The chemical advantage and AI integration

Traditional mechanical recycling, which often degrades fiber length, is being challenged by high-precision chemical processes. Chemical recycling now dominates the sector with a 52.14 per cent market share, enabling the regeneration of polyester and blended fabrics into ‘virgin-quality’ fibers. This technological shift is augmented by AI-powered sorting systems, which have demonstrated the ability to reduce contamination rates by up to 45 per cent. By utilizing near-infrared (NIR) sensors and machine learning, facilities can now identify 13+ fiber types at speeds exceeding one garment per second, solving the long-standing bottleneck of manual labor.

The US market and regulatory tailwinds

The US segment is experiencing an accelerated 7.96 per cent CAGR, significantly outpacing global averages as domestic brands secure consistent feedstock for recycled polyester lines. However, the industry faces a sharp divide: while 70 per cent of consumers demand sustainable fabrics, only 1 per cent of textiles are currently recycled back into new garments. To bridge this ‘circularity gap,’ major retailers are integrating digital product passports to enhance traceability. As landfill bans tighten, the transition toward a closed-loop system is no longer a branding choice but a necessary hedge against rising waste-dispochemical depolymerization sal premiums and regulatory fines.

Circular infrastructure and market outlook

Textile recyclers manage the collection and reprocessing of post-consumer and industrial waste into high-value raw materials. Key markets include North America and Asia-Pacific, with growth focused on chemical depolymerization for polyester. Historically a fragmented sector, it is now scaling through brand partnerships to meet 2030 zero-waste targets.

The Government of India has officially extended the application window for the Production Linked Incentive (PLI) Scheme for Textiles until March 31, 2026. This strategic extension, announced by the Ministry of Textiles on January 2, 2026, aims to capitalize on heightened investor interest in high-growth segments such as Man-Made Fiber (MMF) apparel and technical textiles. By providing an additional quarter for fresh proposals, the government seeks to broaden the industrial base beyond traditional cotton, aligning with the ambitious national target of achieving US$ 100 billion in textile exports by 2030.

Facilitating inclusion and scale

Recent amendments have significantly lowered the barrier to entry, reducing minimum investment thresholds to Rs 50 crore for smaller units and Rs 150 crore for larger projects. These adjustments have already yielded substantial results; as of late 2025, 91 companies have been selected, committing an aggregate investment of Rs 7,731 crore. This fiscal push is designed to move Indian apparel manufacturing toward a vertically integrated model, enhancing cost-competitiveness against global rivals like Vietnam and Bangladesh. The Ministry reports, the scheme has already generated over 30,000 jobs, with turnover figures exceeding Rs 7,200 crore.

Strategic alignment with global standards

The extension arrives as the industry prepares for the National Textiles Ministers’ Conference later this month in Guwahati. Beyond domestic scaling, the PLI framework is being synchronized with global ESG (Environmental, Social, and Governance) mandates. By incentivizing technical textiles - used in healthcare, defense, and automotive sectors - India is diversifying its export basket to mitigate the risks associated with volatile cotton cycles. The revised norms ensure that even mid-sized manufacturers can now integrate into the global value chain, stated a Ministry official, highlighting that the move is essential for leveraging recent Free Trade Agreements (FTAs) with the UK and Australia.

Textile PLI initiative

The Production Linked Incentive (PLI) Scheme for Textiles focuses on promoting MMF apparel, MMF fabrics, and technical textiles. With a total outlay of Rs 10,683 crore, the initiative targets large-scale manufacturing and export growth. Launched in 2021, it aims to transform India into a global textile hub by 2030.

The Indian government has fast-tracked the Market Access Support (MAS) Intervention as a critical buffer for the textile and apparel sector, which is currently grappling with a 50 per cent US tariff hike effective since late 2025. Launched on December 31, 2025, as the first pillar of the Rs 25,060 crore Export Promotion Mission (EPM), the MAS scheme provides a Rs 4,531 crore war chest to diversify India’s apparel footprint beyond traditional Western strongholds. With a mandatory 35 per cent participation quota for MSMEs, the policy is designed to propel small-scale garment manufacturers into emerging high-demand markets like Latin America and Africa.

Financial liquidity and market Reorientation

To counter the ‘challenging year’ described by the Confederation of Indian Textile Industry (CITI), the Ministry of Commerce has paired market access with a Rs 7,295 crore credit package. This includes a 2.75 per cent interest subvention and a Rs 2,114 crore collateral guarantee fund. For textile hubs like Tiruppur, where MSME concentration is high, these measures offer a vital hedge against global headwinds. Small exporters with an annual turnover under Rs 75 lakh are now eligible for partial airfare subsidies, ensuring that the prohibitive cost of international trade fairs no longer stalls the 2030 vision of achieving US$ 100 billion in textile exports.

Digital traceability and global integration

The intervention introduces a mandatory online feedback loop via trade.gov.in, tracking lead generation and buyer quality to refine future trade delegations. This data-driven approach is synchronized with the upcoming Digital Product Passports, aimed at meeting European ESG standards. By shifting from fragmented incentives to a unified, mission-mode framework, India is positioning its apparel sector to leverage zero-duty access through new trade pacts with Australia and the UK. ‘November 2025 data confirms our diversification strategy is already yielding results,’ noted Ashwin Chandran, Chairman, CITI, highlighting the sector's shift toward high-value technical textiles and sustainable MMF apparel.

Export Promotion Mission (EPM) framework The EPM is a Rs 25,060 crore unified trade initiative (2025–2031) targeting labor-intensive sectors like textiles and leather. It integrates financial subventions with market readiness support to boost MSME competitiveness. By consolidating multiple fragmented schemes, the Mission aims to triple India’s textile exports to USD 100 billion by 2030.

The Ministry of Textiles has initiated a comprehensive nationwide survey to map industrial hubs, a move designed to de-risk the sector ahead of a projected US$ 100 billion export growth by 2030. Gaining momentum as of January 2, 2026, this data-driven initiative aims to identify production bottlenecks in over 50 regional clusters, from the knitwear strongholds of Tiruppur to the looming powerhouses in Surat. By establishing a digital ‘health card’ for each hub, the government plans to synchronize infrastructure investment with real-time manufacturing capacity.

Targeted interventions and export diversification

The survey arrives at a pivotal moment as the government extends the PLI Scheme for Textiles until March 31, 2026, following a robust response in the man-made fiber (MMF) and technical textiles segments. With 91 companies already selected and Rs 7,731 crore in investments committed, the mapping exercise will help direct these funds toward under-utilized rural hubs. Our objective is to move from fragmented production to high-scale, vertically integrated units, states a senior ministry official, emphasizing that the data will be instrumental in leveraging the zero-duty access granted by the India-Australia ECTA, which became fully operational on January 1, 2026.

Navigating supply chain volatility

Despite a steady 3.87 per cent rise in cumulative exports reaching US$ 12.18 billion by late 2025, the industry faces headwinds from rising input costs and global shipping disruptions. The mapping project will integrate with the 'KapasKisan' App and blockchain-based QR coding for cotton, ensuring full traceability—a non-negotiable requirement for the European market's tightening ESG regulations. By identifying where the "circularity gap" is widest, India aims to modernize its traditional handloom and powerloom sectors, which currently support nearly 45 million livelihoods, into a globally competitive, high-tech manufacturing powerhouse.

The Ministry of Textiles oversees the entire value chain of the Indian textile industry, which contributes 2.3 per cent to the national GDP. Key initiatives include the PM MITRA parks and the National Technical Textiles Mission. With a vision to reach a US$ 350 billion industry size by 2030, the ministry is currently prioritizing MMF apparel and technical textiles to boost global market share.

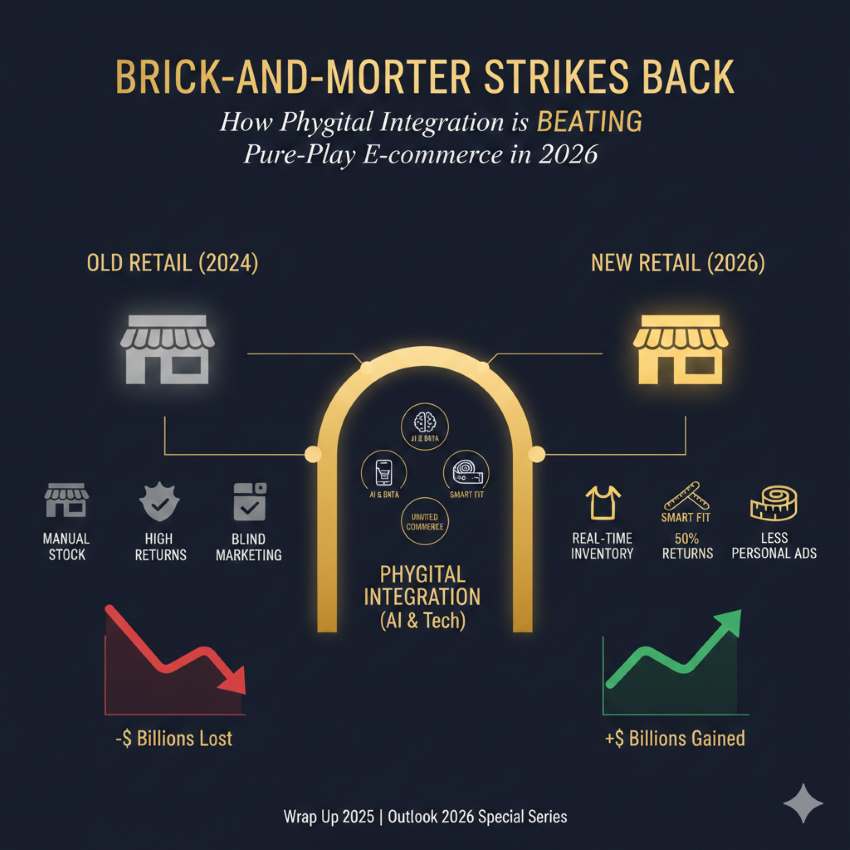

Hong Kong’s apparel and retail landscape demonstrated a resilient trajectory in late 2025, with November retail values rising by 6.5 per cent to HK$33.7 billion. While hard luxury - jewelry and watches - saw a moderated growth of 3.6 per cent, the wearing apparel segment recorded a 3 per cent increase, signaling a steady recovery in consumer discretionary spending. This seventh consecutive month of gains was significantly boosted by a 28.4 per cent explosion in online retail sales, which now account for 11.2 per cent of the city’s total retail turnover.

Digital acceleration and tourism synergy

The retail sector is currently undergoing a structural realignment, moving away from a pure brick-and-mortar reliance. The government’s ‘mega-event’ economy, including the 15th National Games and international art festivals, drove an 11.9 per cent Y-o-Y rise in visitor arrivals. However, the true growth driver has been the ‘omni-channel’ shift. Apparel brands are increasingly leveraging social commerce and live-streaming to capture ‘long-haul’ travelers and local Gen Z shoppers. The sustained recovery in November highlights a stabilization in consumer confidence, noted a government spokesperson, pointing to the 4.4 per cent volume increase as evidence of robust underlying demand.

Navigating 2026: Experience-first retail

Looking toward early 2026, the industry faces the challenge of a strengthening Hong Kong dollar, which has historically encouraged ‘northbound’ spending in Shenzhen. To counter this, retailers are pivoting toward experiential concepts - integrating art installations and ‘phygital’ fitting rooms to justify premium price points. With the HK$1.5 billion injection into the BUD Fund supporting digital transformation, the focus for 2026 is clear: creating frictionless, tech-enabled shopping environments that turn a simple purchase into a cultural experience.

This government-backed strategy repositions Hong Kong as a premier retail hub by integrating technology and tourism. Focused on luxury apparel and ‘silver economy’ products, the initiative aims to reach a HK$400 billion annual sales target by 2027. Established in the post-pandemic era, it emphasizes digital-first licensing and immersive flagship stores.

To forge a unified state-central roadmap for industrial scaling, the Ministry of Textiles is convening the National Textiles Ministers’ Conference in Guwahati on January 8–9, 2026. This summit is being held as the federal government extends the Production Linked Incentive (PLI) Scheme application window to March 31, 2026, signaling an urgent push to fill the manufacturing vacuum in Man-Made Fiber (MMF) and technical textiles. The strategic objective is to synchronize regional policies with the national target of achieving US$ 100 billion in exports and a total market size of US$ 350 billion by 2030.

Enhancing global competitiveness through MMF and technical textiles

A primary focus of the Guwahati deliberations is the structural transition toward high-growth segments like MMF and functional fabrics. While India currently dominates the global cotton yarn market, it lags in the weaving and processing stages where China and Vietnam maintain a cost advantage. To counter this, the government is incentivizing large-scale integrated infrastructure through the PM-MITRA parks. Recent data indicates, India’s textile exports grew by 5.37 per cent in mid-2025, reaching US$ 3.10 billion monthly, yet officials emphasize that achieving the 2030 targets requires a sustained 15 per cent-20 per cent growth rate.

Unlocking the North-East textile corridor

The conference includes a dedicated conclave aimed at transforming North-East India into a specialized hub for sustainable and high-value textiles. By focusing on bamboo-based fibres, Muga silk, and handloom-driven women’s enterprises, the Ministry intends to brand ‘Textiles from North-East’ as a premium global category. This initiative is about integrating regional craftsmanship with global value chains to ensure our traditional heritage meets modern technical standards, states a senior official. The integration of sustainable practices and green chemistry is expected to be a key differentiator for Indian apparel in ESG-compliant Western markets.

Policy framework and sectoral objectives

The Ministry of Textiles oversees the entire value chain from fibre production to retail. Current growth plans involve operationalizing seven PM-MITRA parks and leveraging the Rs 10,683 crore PLI scheme to boost MMF output. Financially, the sector contributes 2.3 per cent to India's GDP, with a roadmap to triple current export volumes by 2030.

In South Korea, China, and the United States, clothing retail sales have maintained year-on-year growth, driven by each country's economic stimulus measures. As apparel inventories decrease, there is analysis suggesting that the stock prices of textile and apparel-related companies, which have bottomed out, could rebound.

On January 2, Shinhan Investment Corp. maintained its overweight recommendation on the textile and apparel sector, citing these factors. The firm selected Youngone Corporation as its top pick, while also highlighting F&F, Gamsung Corporation, and AU Brands as stocks to watch.

From the second half of last year through November, the clothing retail sales growth rate in South Korea, China, and the United States averaged around 3 per cent Y-o-Y. Certain segments, such as women's apparel, saw growth rates reaching the low double digits. Notably, apparel inventory levels in both South Korea and the United States are currently at their lowest points in the past three years, fueling expectations for increased shipments.

In South Korean department stores, women's apparel has maintained around 5 per cent Y-o-Y sales growth since June of last year. Casual wear, men's clothing, and children's and sports apparel also saw department store sales growth throughout the second half of the year, except for September. While the luxury segment continued to post sales growth in the low double digits, deepening consumption polarization, it is noteworthy that department store apparel sales have grown for five consecutive months for the first time in two years since 2023, which is seen as an encouraging sign.

Having outperformed the market in sales growth during the second and third quarters of last year, Gamsung Corporation is estimated to have achieved sales growth exceeding 20 per cent Y-o-Y from October to early December. Similarly, clothing retail sales in China are estimated to have grown by 3-5 per cent Y-o-Y in the second half of last year. With the base effect expected to be pronounced through the first half of this year, China's clothing retail sales are anticipated to maintain their growth momentum for the time being. This is why attention is being paid to companies such as F&F, Gamsung Corporation, and AU Brands, which are planning to expand into China this year.

The reduction in inventory is also a positive signal. Recently, apparel inventory levels in the United States have remained at the lower end since 2023. The report emphasized that attention should be paid to the potential for earnings recovery among original equipment manufacturing (OEM) companies this year. However, it remains uncertain whether American consumers will maintain their purchasing power in the face of inflation driven by tariffs. Lagging indicators that could confirm this are expected to emerge after the first quarter of this year, but until then, investment sentiment may be concentrated on OEM companies.

Park Hyunjin, a researcher at Shinhan Investment Corp, stated, Youngone Corporation's investment appeal may further increase, as its sales are expected to grow significantly due to benefits from certain clients, even though its correlation with consumer sentiment is low. ‘This presents an opportunity for its price-earnings ratio (PER) multiple to expand, he added.

Luxury fashion availability in Russia has entered a new phase of logistical complexity as the market adapts to the EU’s expanded export prohibitions. Despite a formal ban on European luxury goods with wholesale values exceeding €300, iconic labels including Gucci, Burberry, and Dolce & Gabbana remain prominently featured in Moscow’s flagship department stores. However, the cost of circumvention is being passed directly to the consumer. A comprehensive price audit of 600 luxury items at TSUM reveals, Russian shoppers are currently paying an average of €2,626 for goods that retail for €1,229 in Paris or Milan - a staggering 113 per cent premium.

Logistics arbitrage and third-country rerouting

The persistence of European apparel and accessories is underpinned by a sophisticated network of ‘parallel imports’ and personal shopping intermediaries. Customs data from the first quarter of 2025 indicates,major Russian distributors are successfully sourcing high-value inventory via Turkey, the United Arab Emirates, and China. While direct shipments from the EU are strictly limited to lower-priced "entry-level" luxury items to remain compliant with the €300 threshold, boutique agencies like Global Style Import are declaring high-end silk dresses and leather bags at significant markups after transshipment through neutral hubs.

The rise of the status premium

This bifurcated supply chain has transformed the Russian luxury landscape into a ‘status-for-scarcity’ model. While mid-market brands struggle with a 2.8 per cent decline in real disposable income, the ultra-wealthy demographic remains relatively price-inelastic. Investors are closely monitoring how this ‘sanctions tax’ affects the broader apparel sector, which saw a 4.3 per cent reduction in physical store counts by mid-2025. Paradoxically, the high cost of acquisition has only served to reinforce the exclusivity of Western brands, even as domestic manufacturers and Iranian leather labels attempt to capture the resulting market vacuum.

Mercury Fashion, Russia’s premier luxury distributor since 1993, operates the TSUM department store and various high-end boutiques. Despite geopolitical headwinds, it maintains a robust digital presence and 95 per cent in-store conversion rates. The firm is currently leveraging a ‘compliant direct-import" model for accessories while utilizing third-party logistics for heritage couture.

The American retail landscape underwent a seismic restructuring in 2025, defined by the collapse of legacy fast-fashion icons under the weight of ‘ultra-fast’ digital competition. Data from Coresight Research confirms, roughly 8,200 stores shuttered nationwide last year - a 12 per cent rise from 2024 - marking the highest level of retail volatility since the pandemic. The most striking casualty was Forever 21, which wound down all US operations after failing to defend its mall-based empire against the aggressive pricing of cross-border e-commerce giants.

The pricing chasm and the de minimis shift

Strategic missteps in physical site selection were exacerbated by a pricing war Forever 21 could not win. While the brand struggled with rising domestic labor costs and brick-and-mortar overhead, overseas competitors like Shein and Temu leveraged a $100 billion global scale to capture cost-conscious Gen Z shoppers. However, the sector faces a new turning point in early 2026 as the federal government eliminates the ‘de minimis’ trade exemption. This policy shift, which previously allowed duty-free entry for packages under $800, is expected to drive up import costs for digital retailers, potentially offering a slim window of opportunity for surviving domestic apparel brands.

Shifting toward experience and value

As discretionary spending on durable goods is projected to rise by 4.7 per cent in 2026, the industry is witnessing a ‘Great Retail Reset.’ Legacy survivors are moving away from the high-volume, low-quality model that doomed Forever 21. Retail analysts note a decisive trend toward ‘phygital’ strategies - merging interactive in-store experiences with seamless digital fulfillment. The retailers that will thrive are those who view their physical footprint as a strategic advantage rather than a liability, noted one industry CEO. With inflation easing to 2.3 per cent, the focus is now on justification of price through quality, as consumers trade blind brand loyalty for tangible value and sustainability.

Retail restructuring and legacy management

Forever 21 was a Los Angeles-based fast-fashion pioneer that once operated 800 global stores. Following its 2025 liquidation, its brand intellectual property remains under Authentic Brands Group. The company is now exploring a digital-only licensing model to service international markets while exiting high-cost US physical real estate entirely.