This feature marks the second article in our exclusive series, "Wrap Up 2025 | Outlook 2026," where we dissect the structural shifts redefining the B2B textile and apparel landscape.

As the final bobbins of 2025 spin to a halt, the global textile and apparel industry is not merely turning a page; it is burning the old playbook. While 2025 was defined by a desperate race to dodge the "Reciprocity Tariffs" of a volatile US trade regime, 2026 is emerging as the year of the Compliance Corridor—a structural reality where market access is no longer dictated by the lowest bid, but by the most robust data set. The overarching play and role of countries in this new era is dictated by a historic structural bifurcation. For the global sourcing community, the focus has shifted from simple labor arbitrage to navigating a "Digital Border" where a product's entry into the European Union or North America depends on a verifiable "Data Birth Certificate."

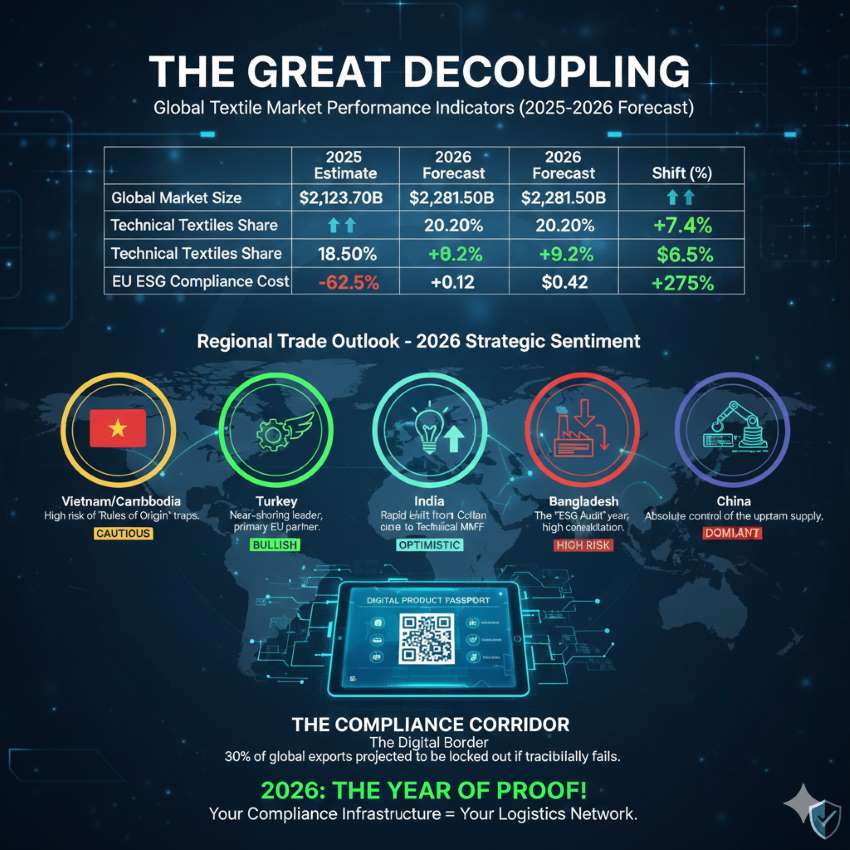

The Regional Trade Outlook for 2026 confirms that we are moving toward a period of profound structural permanence. By mid-2026, the EU’s Digital Product Passport (DPP) registry and the Corporate Sustainability Due Diligence Directive (CSDDD) will go live, effectively creating a regulatory wall projected to lock out nearly 30% of current global exports that fail the traceability test.

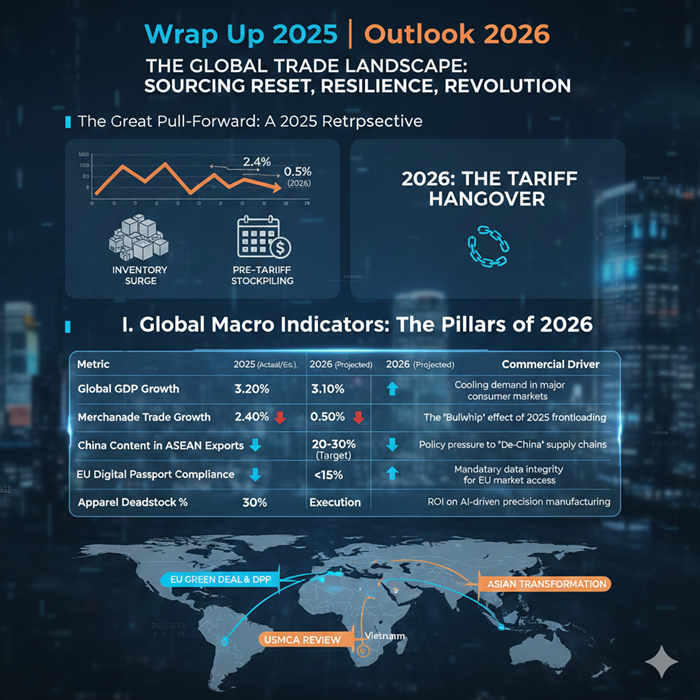

The Global Macro View: A two-speed trade reality

Trade dynamics in late 2025 were characterized by "Pre-emptive Shipping." Importers in the United States front-loaded inventories to hedge against tariff spikes, while European buyers braced for the implementation of the EU Strategy for Sustainable and Circular Textiles. This has created a "Bullwhip Effect" heading into 2026: a cooling of demand as brands digest excess stock, followed by a frantic search for "Safe Havens"—territories with stable Free Trade Agreements (FTAs) and low geopolitical friction.

While the global textile market is projected to reach $2.28 trillion in 2026, the growth is no longer uniform. Technical textiles and Man-Made Fibers (MMF) are growing at double the rate of traditional apparel, reflecting a C-suite obsession with high-performance applications in the automotive, medical, and defense sectors.

Table 1: Global Textile Market Performance Indicators (2025–2026 Forecast)

|

Metric |

2025 Estimate |

2026 Forecast |

Shift (%) |

|

Global Market Size (USD Billion) |

$2,123.70 |

$2,281.50 |

+7.4% |

|

Technical Textiles Share (%) |

18.50% |

20.20% |

+9.2% |

|

US Sourcing Costs (Avg. YoY) |

+12.0% |

+4.5% |

-62.5%* |

|

EU ESG Compliance Cost per Unit |

$0.12 |

$0.45 |

+275% |

*Reflects stabilization after the 2025 tariff shock.

Vietnam and Cambodia: The middlemen’s dilemma

Vietnam and Cambodia enter 2026 as the primary beneficiaries of the "China-Plus-One" strategy, yet they are walking a regulatory tightrope. Despite a projected $46 billion in exports for Vietnam in 2025, a "Transparency Gap" remains. OECD (Organisation for Economic Co-operation and Development) data reveals that 20–30% of the value-added in their exports—specifically high-performance fabrics—still originates in China. As "Rules of Origin" enforcement becomes automated through AI-driven customs tracking, these nations face a "Compliance Cliff." To maintain their 2026 trajectory, they are being forced to localize their upstream supply chains, moving away from simple assembly toward domestic spinning and weaving to satisfy both USMCA (United States–Mexico–Canada Agreement)-style "Yarn Forward" rules and EU traceability mandates.

Turkey & North Africa: The speed king’s dominance

Turkey has secured its position as the definitive "Speed King" for the European market, delivering "Green Denim" within a 14-day window. Strategic proximity allows Turkish and Moroccan exporters to reach European capitals by road in under 72 hours, bypassing the volatility of 2026 ocean carrier surcharges. This is a massive commercial lever; near-shoring to Turkey now provides an estimated 12% landed-cost saving over traditional Asian routes when accounting for transit-tied capital and new regulatory premiums. By 2026, Turkey is no longer just a sewing hub but the "Technology Hub for Global Denim," leading the transition to waterless dyeing and circular material usage.

India: Scaling the technical upgraders

India is executing a massive industrial upgrade, moving "Beyond Basic Cotton." Leveraged by the government’s Production Linked Incentive (PLI) scheme, Indian industrial giants are scaling up in high-value MMF and Technical Textiles. India’s technical segment is expected to hit a 10% CAGR by the end of 2026, offsetting headwinds in traditional cotton knits. As one industry leader stated, "We are no longer just the world’s cotton patch; we are becoming a high-complexity material partner." This diversification into automotive and medical textiles has allowed India to remain resilient despite fluctuating global demand for fast fashion.

Bangladesh: The €18 bn question of compliance

For Bangladesh, 2026 is the year of "Compliance or Collapse." Following its scheduled graduation from Least Developed Country (LDC) status in November 2026, the nation faces the potential loss of the EU's "Everything But Arms" (EBA) preferences. While the EU has offered a transition period until 2029, the immediate pressure lies in the mandatory labor and environmental audits under the CSDDD. 2026 is becoming a period of intense consolidation; global brands are narrowing their supplier bases to only those who can provide real-time visibility into wage transparency and chemical discharge. Bangladesh must decide whether to invest billions in green infrastructure or risk losing its most lucrative trade partner.

China: The upstream giant and global supplier

China has successfully transitioned to become the "Supplier to the World's Suppliers." While its share of finished apparel assembly has slipped, its grip on global textiles; yarns, fabrics, and chemicals has grown to a commanding 43%. In 2026, China effectively owns the "guts" of the global industry. Even as a garment is sewn in Southeast Asia, the technology and material that made it likely originated in a smart-mill in Zhejiang. China’s 2026 strategy is one of "Industrial Supremacy through Innovation," focusing on chemically recycled fibers and high-automation that competitors cannot yet match at scale.

Table 2: Regional Trade Outlook - 2026 Strategic Sentiment

|

Region |

Status |

The 2026 Narrative |

Market Sentiment |

|

Vietnam |

The Middleman |

High risk of "Rules of Origin" traps. |

Cautious |

|

Turkey |

The Speed King |

Near-shoring leader; primary EU partner. |

Bullish |

|

India |

Scale Upgrader |

Rapid shift from Cotton to Technical MMF. |

Optimistic |

|

Bangladesh |

Compliance Gamble |

The "ESG Audit" year; high consolidation. |

High Risk |

|

China |

Textile Giant |

Absolute control of the upstream supply. |

Dominant |

C-Suite Strategic Outlook: The "Asset-Light" CEO

The leadership model for 2026 is the Asset-Light CEO. Strategic leaders are moving away from owning the entire production line toward a "Supply Web" model, utilizing Manufacturing-as-a-Service platforms to launch collections without heavy inventory. CFOs are now treating "Reverse Logistics" not as an expense, but as a secondary revenue stream. Resale, repair, and rental models are being integrated directly into balance sheets as brands seek to meet the EU's new longevity standards. Leadership in this era is about managing data as much as fabric; if you cannot prove your product's journey from Tier-4 raw material to the retail floor, you simply do not have a product in 2026.

Editor’s Conclusion: The dawn of total transparency

As we look toward the 2026 horizon, the "Great Decoupling" of the textile industry is final. We have decoupled from the belief that cheap labor is a permanent competitive advantage and from the "Black Box" supply chain where the origin of raw materials was a mystery. The winner of 2026 is the Transparent Brand-the one that can provide a "Data Birth Certificate" for every garment. Trade policies and FTAs are no longer just about taxes; they are about values and verifiable proof. In this new era, your compliance infrastructure is just as vital as your logistics network. 2026 is the year of Proof!