Vietnam is one of the world’s top apparel exporters. But 70 per cent of its textile makers are working as sub-contractors on medium and small scales and are still weak in fiber manufacturing, weaving and dyeing. Almost all input materials come from China and Korea. The rate of locally-made products in the sector stands at a mere 55 per cent due to the weak weaving and dyeing capability.

Weaving and dyeing projects fail to receive licenses due to their high risk of environmental pollution. What’s needed is zoning off regions and areas exclusively designed for weaving and dyeing and equipped with infrastructure and waste treatment facilities.

Vietnam faces another challenge. Once the Trans-Pacific Partnership (TPP) comes into force, regulations on the origin of goods will follow. Vietnam must follow TPP’s yarn-forward rule of origin which requires that only textile and apparel products using the US and other TPP countries’ yarns and fabrics qualify for the benefit of the agreement.

The strength of Vietnam’s textile and garment industry is that only a small capital investment is called for. The payback period is quick because of a short capital turnover. The industry gets preferential policies. Greater product differentiation and specialisation can boost margins.

Vietnam to work on weaving, dyeing

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

New markets, new factories, India’s apparel industry looks to Africa

In the quiet industrial corridors of Ethiopia’s Hawassa Industrial Park, rows of sewing machines with local workers assemble garments destined... Read more

From Imports to Innovation: India’s bid to lead the carbon fibre economy

A new report highlights the global carbon fibre and yarn market growing and how. The report by Thryve Research projects... Read more

ITMF Annual Conference & Annual Convention: Addressing industry challenges a…

This year, the ITMF Annual Conference & Annual Convention will be held from October 24-25, 2025 at Yogyakarta. Co-hosted by the... Read more

China’s Carbon Ambition: From industrial giant to climate market leader

When Beijing announced plans to enter the international carbon markets this October, the message was unmistakable: China no longer intends... Read more

Fashion’s double bind, innovation meets the economics of convenience

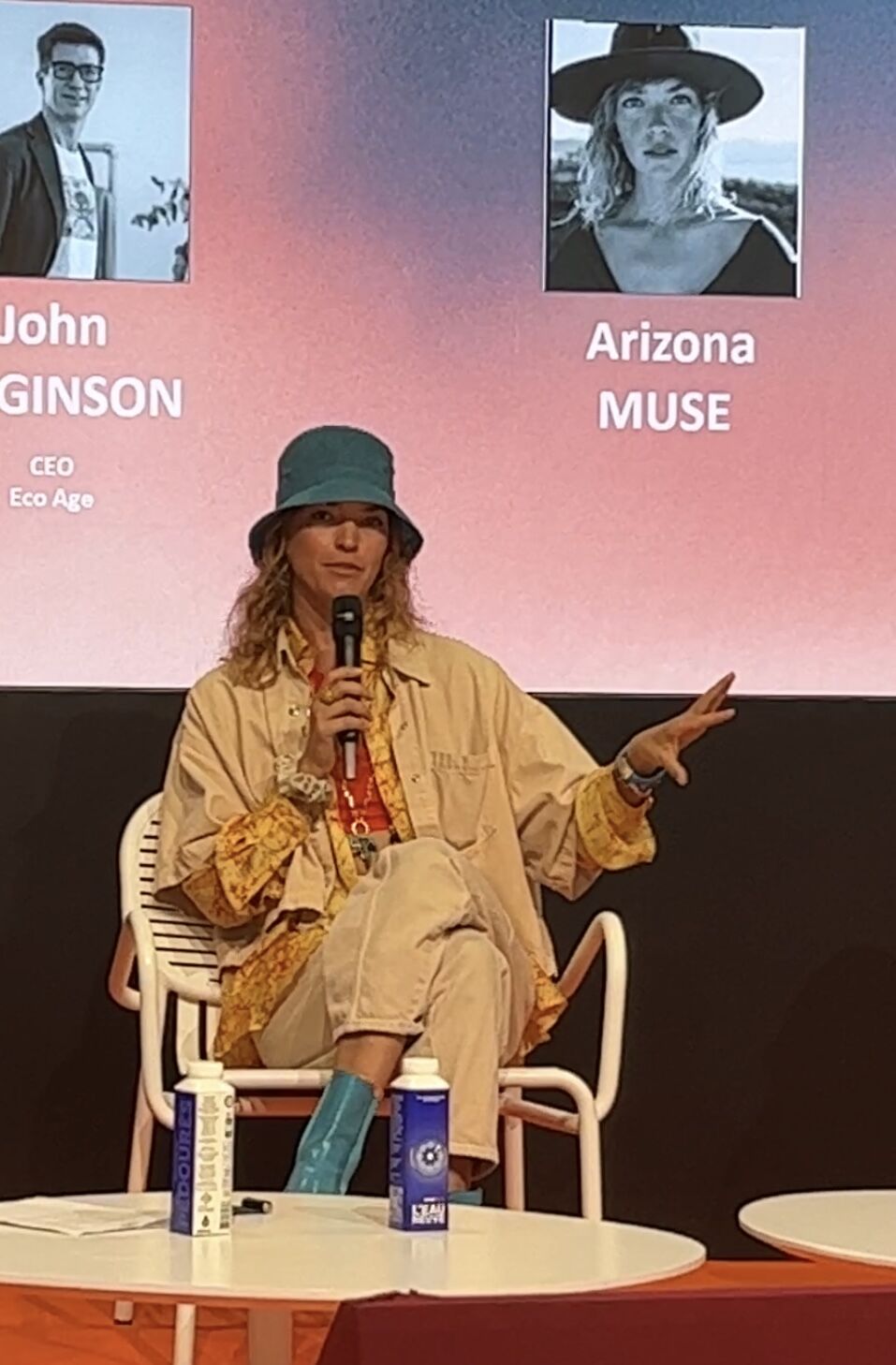

“We need to make fashion for worms. Fashion that can decompose in the soil.” When Arizona Muse, model and environmental... Read more

From satin to smart textiles, the rise of FDY in a changing market

In the complex world of polyester filament yarns, where POY (Partially Oriented Yarn) is the foundation and DTY (Drawn Textured... Read more

Polyester’s reign vs. Lyocell’s strain, can green fibers survive?

The recent job cuts announced by Lenzing, a pioneer in sustainable cellulosic fibers, are a stark reflection of the complex... Read more

Indian Textile and Apparel Exports Hit Hard in September: As US tariffs take hol…

The Indian textile and apparel industry has shown the first clear signs of being impacted by the new US tariffs,... Read more

Fast, cheap, unstoppable, Shein shockwave hits Germany’s fashion retial

In a country known for its deep-rooted retail traditions, discerning shoppers, and a growing emphasis on sustainability, the rise of... Read more

Europe’s Circular Turn: The Danish vision shaping a new industrial era

In a speech that captured both urgency and ambition, Danish MEP Rasmus Nordqvist stood before an audience of European policymakers,... Read more