Textile maker Unifi based in the US produces 300 million pounds of polyester and nylon yarn annually.Unifi does recycling through its flagship fiber brand Repreve, launched in 2009.

Repreve has a 50,000 sq ft recycling facility, where plastic bottles, fiber waste and fabric scraps get deposited.

The company collects clear plastic bottles from processors around the country who first shred them into plastic flakes. These plastic flakes are converted into small pellets. The pellets are then melted, extruded and spun into polyester yarn.

Repreve makes three types of recycled yarn: 100 per cent from used plastic bottles, a hybrid of plastic bottles and fiber waste, and a hybrid of plastic bottles and used fabric.

College students across the US accept their diplomas wearing gowns made entirely of plastic bottles. Through such gowns schools can spread the message of waste management, energy conservation and environmental protection.

Repreve yarn is used to make everything from jackets and T-shirts to dress pants and even car upholstery. It’s used in brands like Patagonia, The North Face, Levi’s, Adidas, Nike and Ford.

Unifi has turned four billion used plastic bottles into yarn in the last seven years. It wants to educate consumers that high quality products can be made from recycled waste.

Repreve makes gowns out of plastic bottles

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

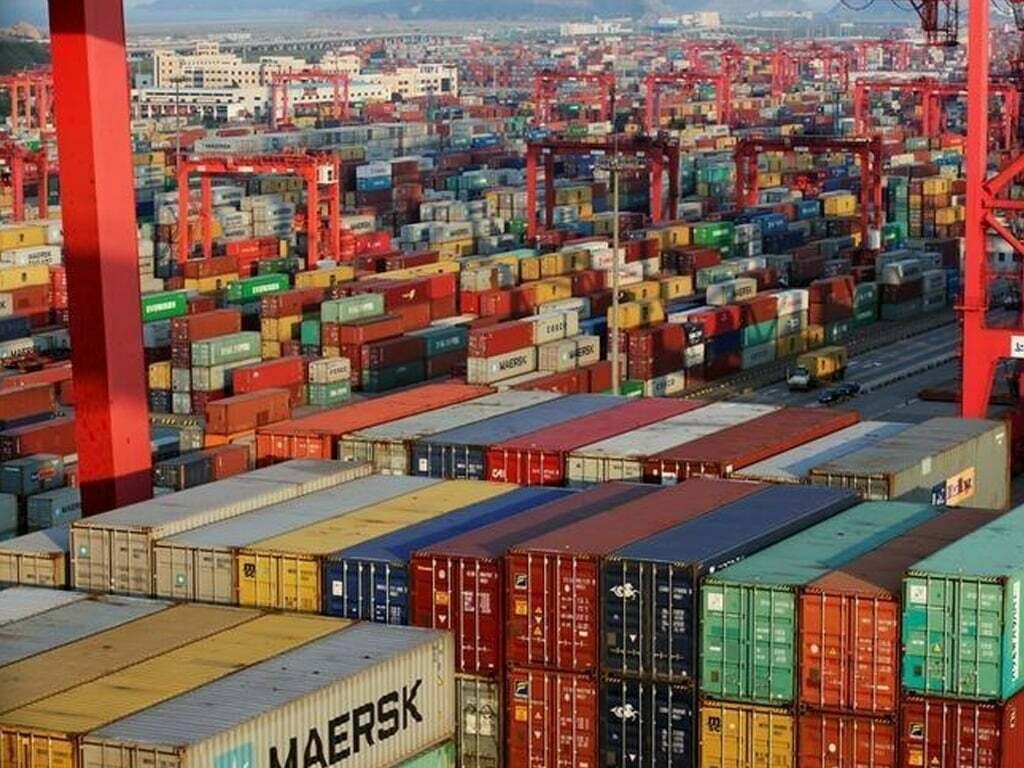

Nomura Report: Asian exporters absorb tariffs, rethink supply chains

As global trade enters a period of recalibration, Asian exporters are bearing the brunt of escalating US tariffs while simultaneously... Read more

Fashion's New Fit: Tailoring and alteration services stitch a story of growth

From the runways of Paris to the digital storefronts of global e-commerce, the fashion industry is changing. As consumers increasingly... Read more

Luxury brands swap leases for deeds as global real estate strategy shifts

Luxury fashion houses are increasingly choosing to buy, not rent, the world’s most coveted retail spaces, marking a sharp shift... Read more

STAR Network joins hands with Fashion Industry Charter for Climate Action to adv…

An inter-regional alliance of garment producer associations, The Sustainable Textiles of the Asian Region (STAR) Network, has reaffirmed its commitment... Read more

More than a lookalike, 'dupe' culture is forcing premium brands to innovate

The $4.5 trillion global luxury market is under siege, not just from the traditional counterfeiters operating in back alleys and... Read more

Recycling at Risk: How virgin polyester growth threatens fashion’s green goals

The global fashion industry is facing a sobering contradiction. Even as some of the world’s largest apparel brands proudly champion... Read more

The BRICS+ Fashion Summit: Redefining fashion business in a new global order

The recently concluded BRICS+ Fashion Summit & Moscow Fashion Week ( Aug 28 to September 2, 2025) has solidified its... Read more

Beyond the label, RepRisk flags human rights and environmental hazards in fashio…

The global apparel and textile industry, long celebrated for its role in democratizing fashion and creating jobs across continents, is... Read more

Made abroad, worn at home imports are replacing US garment production

The story of America’s clothing industry is one of contrast: booming demand from consumers but shrinking capacity at home to... Read more

Uniform GST rate ends duty anomalies, brings relief to textile manufacturers

When Finance Minister Nirmala Sitharaman rose to chair the latest GST Council meeting, few expected the sweeping changes that would... Read more