Latest stats from the US Bureau of Labor Statistics reveal, prices of men’s apparels rose 5 per cent in October 2023 as against the previous year. Comparatively prices of women’s apparels, rose just 1.6 per cent during the month. Prices of all items in men’s wear category surged 3.2 per cent in October, which was less than half the 7.8 per cent increase seen a year earlier.

Over the past decade, prices of men’s apparel have increased by around 2 per cent. Most of this rise is led by a 14.2 per cent increase in prices of underwear, nightwear, swimwear and accessories and an 8.9 per cent boost in the prices of pants and shorts.

A host of factors have worked together to push up prices these included the cost of raw materials and production. In contrast, prices of women’s wear have declined by 6.2 per cent since October 2013. In fact, prices of women’s dresses have registered a massive decline 17.3 per cent.

Tiruppur Exporters Association says they have observed heightened demand for budget-friendly garments this year. Basic T-shirts, priced at $2 per piece, are experiencing a surge in popularity, overshadowing demand for fashion garments priced between $8 and $20 per item. Even during Christmas and New Year season, apparel trade in the country has failed to witness the usual joy, mainly due to a slowdown in demand from the US and European markets.

As Raja Shanmugam, Managing Director of Warsaw International, both US and European markets are grappling with high inflation resulting from increased post-pandemic demand and supply chain disruptions amid the Russia-Ukraine war. KM Subramanian, President of the Tiruppur Exporters Association, notes demand during the Christmas and New Year seasons has declined almost 40 per cent. The smaller units within the industry have been particularly adversely affected by this downturn.

Spanish eco-technology pioneer, Jeanologia, is showcasing its cutting-edge advancements at ITMA Asia 2023, held at the Shanghai National Convention and Exhibition Center from November 19 to 23. Positioned at stand H6A11, the company is unveiling disruptive technologies set to revolutionize the Chinese textile industry, emphasizing efficiency and sustainability.

At the forefront of these innovations is the ability to produce vintage-style garments without water consumption, waste minimization, and zero discharges. Leveraging digitalization and hyper-automation, Jeanologia aims to propel the Chinese textile industry into a new era of eco-efficiency.

Jean-Pierre Inchauspe, Business Director at Jeanologia Asia, notes the company's 18-year commitment to supporting the Chinese textile industry in its journey toward digitalization and sustainability while concurrently reducing costs. The introduction of the Jeanologia Hub in Hong Kong in 2020 has furthered collaboration, enhancing the industry's competitiveness.

Inchauspe announces a pivotal shift with the incorporation of air-led technologies, marking a new phase for the Chinese textile industry. Embracing a circular approach, the innovations promise an eco-efficient, digital, and automated production process.

Among the featured technologies is the atmospheric washing process using G2 ozone technology, achieving garment aging with minimal water usage and eliminating chemical or pumice stone use. The Flash system, a novel laser technology, stands out for its dynamic energy control, enabling faster garment marking with unparalleled efficiency.

Jeanologia's Colorbox technology for garment dyeing is also highlighted for its eco-friendly approach, significantly reducing water, chemicals, energy, and salt usage compared to traditional methods.

With over 15 years of collaboration with the Chinese textile industry, Jeanologia solidifies its position as a technological partner, boasting over 100 clients, 300 installed pieces of equipment, and contributing to 10% of jeans production in China. The company's local teams continue to support the industry, driving sustainability and efficiency benchmarks.

RUDOLF HUB1922 takes a groundbreaking leap in response to the surging demand for truly sustainable technologies, particularly within the textile and apparel industry. Unveiling its revolutionary textile chemistry at Denim by Premiere Vision Milan, the company introduces a visionary range that signifies a genuine evolution. This innovative chemistry represents a significant stride in addressing the critical need for sustainable solutions, utilizing raw materials sourced from organic and plastic waste, as well as renewable feedstock.

Head of RUDOLF HUB1922, Alberto De Conti, underscores the radical nature of this evolutionary textile chemistry, asserting that the approach confronts waste generation by transforming discarded materials into valuable resources. The utilization of waste and renewable feedstock for textile chemical production marks a paradigm shift, reducing the industry's reliance on non-renewable resources and endorsing a circular economy model.

De Conti emphasizes the importance of effective communication and education for the successful integration of chemicals derived from organic and plastic waste, along with renewable feedstocks. He highlights the necessity for collaborative efforts among scientists, fashion designers, and manufacturers, stating that such partnerships are paramount for propelling a collective shift towards sustainable practices. According to De Conti, this collaborative approach makes eco-friendly fashion the standard, minimizing the industry's environmental impact and fostering a more sustainable future.

Bluesign, a pioneering force in environmental stewardship within the fashion industry since its establishment in 2000, continues to reshape the textile landscape through strategic partnerships and innovative solutions. Collaborating with industry giants like Patagonia, Eileen Fisher, Nike, and Adidas, bluesign has elevated the bar for sustainable practices, emerging as a premier provider of eco-conscious solutions.

A recent milestone is the collaboration between bluesign and ERCA, resulting in the revolutionary REVECOL line. Developed in conjunction with ERCA's Textile BU, this product range seamlessly fuses high-performance attributes with a commitment to well-being and environmental preservation. ERCA's rigorous testing for biodegradability and aquatic toxicity, coupled with the GRS certification for the REVECOL range, underscores a new standard for responsible manufacturing, aligning perfectly with YKK's Sustainability Vision 2050.

Madewell, a frontrunner in mainstream sustainable fashion, joined forces with bluesign in 2022 to revolutionize denim production. Their collaboration emphasizes environmental enhancements, worker safety, and resource efficiency, introducing bluesign Approved ISKO fabrics and establishing the "bluesign DENIM" concept—a benchmark for clean chemistry and sustainable production processes.

In a significant move toward sustainable footwear, Vibram and bluesign formed a dynamic partnership in November 2022, driving progress in chemical standards. Their collaboration on certifying Vibram's Component Shoe signifies a notable stride towards a sustainable future in footwear production.

Bluesign and its brand partners, at the forefront of environmental consciousness, are steering the industry toward a more sustainable and responsible future.

In its just released estimate for October 2023, Cotton Association of India (CAI) has reduced cotton pressing estimate for 2023-24 crop year by one lakh bales to 294.10 lakh bales of 170 kg each. The Association had previously estimated cotton pressing to remain at 295.10 lakh bales. CAI estimates total cotton supply in October 2023 to have remained at 54.74 lakh bales of 170 kg each. This includes arrivals of 24.34 lakh bales, import of 1.50 lakh bales and the opening stocks at 28.90 lakh bales of 170 kg each at the beginning of the season.

Cotton consumption estimated in October 2023 is at 26 lakh bales of 170 kg each while it expects export shipments to be approximately one lakh bales. Cotton stocks by the end of October 2023 are estimated to reach 27.74 lakh bales. These include, 25 lakh bales with textile mills and the remaining 2.74 lakh bales with CCI, Maharashtra Federation and others (MNCs, traders, ginners, etc.) including cotton sold but not delivered.

The total cotton supply till 2023-24-end is estimated at 345 lakh bales against last year’s total cotton supply of 355.40 lakh.

Cotton pressing numbers estimated for the season include 294.10 lakh bales of 170 kg each while imports are estimated at 22 lakh bales. CAI also estimates exports to be lower by 1.50 lakh bales of 170 kg each in the ongoing 2023-24 season compared to last year.

In a recent development, the Cotton Association of India (CAI) has revised its cotton pressing estimate for the ongoing 2023-24 season, signaling potential challenges in the cotton sector. The CAI, after a virtual meeting of its Crop Committee on November 17, 2023, announced a downward adjustment of 1 lakh bales, bringing the new estimate to 294.10 lakh bales of 170 kgs. each. This revision raises concerns about the state of cotton production, particularly in Haryana, where reports of damage due to pink bollworm infestation and farmer-driven uprooting of cotton plants prompted a reduction in pressing numbers.

The CAI's October supply figures indicate a total supply of 54.74 lakh bales for the month, comprising arrivals of 24.34 lakh bales, imports of 1.50 lakh bales, and an opening stock of 28.90 lakh bales. However, the pressing estimate for October stands at 26 lakh bales, leaving a lower closing stock of 27.74 lakh bales.

The Crop Committee, consisting of 18 members representing various cotton-growing regions, maintained the consumption estimate at 311 lakh bales for the entire season, mirroring the figures from the previous year. Notably, cotton imports for the 2023-24 season are expected to reach 22 lakh bales, a significant increase of 9.5 lakh bales compared to the previous year. Meanwhile, exports are estimated to be 14 lakh bales, representing a slight decline from the previous season.

The CAI's projections for the closing stock as of September 30, 2024, highlight a decrease to 20 lakh bales, down from 28.90 lakh bales in the previous year. This may indicate potential challenges in meeting demand in the coming months.

As the industry grapples with uncertainties, stakeholders will closely monitor pressing numbers and assess whether further adjustments are necessary. The CAI's decision to maintain the consumption estimate while revising pressing figures underscores the intricate dynamics at play in the cotton sector, requiring a delicate balance between supply and demand.

In a groundbreaking collaboration, textile industry leaders Recover, Evlox, and Jeanologia are set to unveil their revolutionary recycled denim capsule collection, REICONICS, at Milan's Denim Première Vision on November 23-24. The project integrates the expertise of each company, presenting a holistic approach to enhancing circularity within the denim industry, encompassing the entire production process from fiber to finish.

The REICONICS collection, crafted from Recover recycled cotton fiber and Spanish cotton, holds GRS certification and pays homage to classic denim fabrics of past decades. With a focus on eco-design, transparency, process measurement, traceability, and scalability, the collection seeks to inspire and add value to the industry by creating truly circular products.

Comprising premium denim fabrics by Evlox and 14 final garments, the collection showcases Jeanologia's innovative technology, reducing water and energy consumption while eliminating harmful emissions. Remarkably, a single jacket in the REICONICS line, incorporating 32% Recover recycled fiber and Jeanologia finishing, conserves up to 240 liters of water compared to its conventional counterpart.

Alfredo Ferre, CEO at Recover, expressed pride in contributing to the groundbreaking project, emphasizing its potential to guide brands towards a more sustainable future. Francisco Ortega, Evlox R&D Director, and Enrique Silla, CEO at Jeanologia, echoed the sentiment, underscoring the collection's role in reshaping the future of denim manufacturing, making circular fashion accessible without compromising heritage.

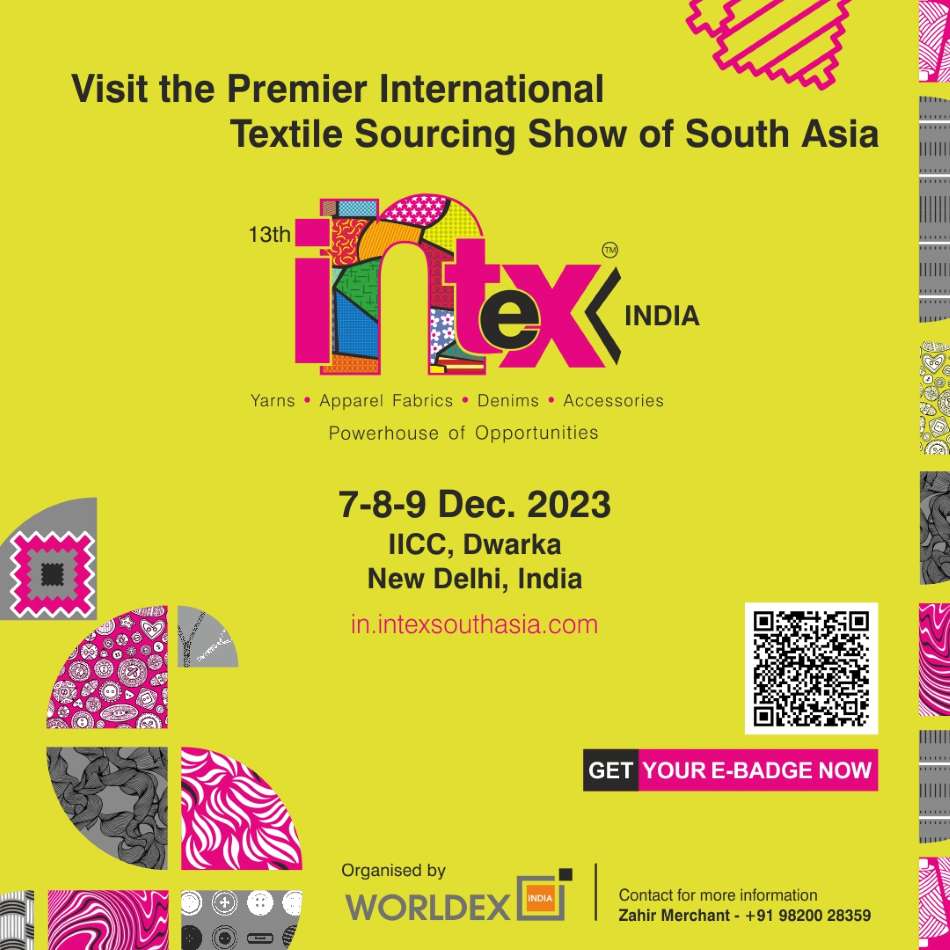

Intex India has established itself as the premier sourcing destination for textile and apparel industry professionals, providing a comprehensive platform that encompasses sourcing, networking, learning, and innovation across the entire textile value chain. With its extensive global reach and unwavering commitment to excellence, Intex plays a pivotal role in shaping the future of textiles, not only in India but across South Asia.

A Catalyst for Growth and Innovation

Intex India serves as an unrivaled B2B international textile sourcing event, attracting a multitude of exhibitors, buyers, and professionals who are integral to the textile and apparel industry's vibrancy. It fosters seamless connections between exhibitors and buyers from diverse regions across the world, offering comprehensive sourcing solutions and access to the rich and diverse tapestry of the textile and apparel industry.

A Hub for Knowledge Sharing and Business Expansion

Intex India provides a unique opportunity for networking, knowledge sharing, and business expansion, catering to a wide spectrum of professionals, ranging from textile manufacturers and suppliers to designers and entrepreneurs.

The trade show showcases the latest textile innovations and industry trends, functioning as a hub for the exchange of ideas and knowledge, facilitating discussions on sustainable practices, digital advancements, and design innovations that are shaping the textile landscape.

A Testament to Continued Growth and Success

Since its inception in 2015, Intex has gone from strength to strength. Through the past 12 editions, it has connected over 50,000 trade buyers from over 35 countries with over 1,850 textile suppliers from 20 countries. This remarkable track record underscores the event's continued growth and its vital role in facilitating international trade relations.

An Immersive Experience for Industry Professionals

Intex India 2023 transcends being a mere exhibition. It offers an immersive experience for professionals, with special forums that serve as platforms for industry leaders to exchange ideas, knowledge, and insights. These forums include:

Intex Textile Conclave (ITC): An inspiration and innovation exchange where the industry's brightest minds come together to share their vision for the future.

Intex Investment Forum (IIF): An opportunity to explore the investment potential in India and globally, paving the way for business expansion and collaboration.

Interactive Business Forum (IBF): A convergence of ideas and businesses, where industry leaders chart the course for future growth and development.

A Force Shaping the Future of Textiles

As the industry evolves and transforms, Intex India has emerged as a consistent and indispensable force, contributing significantly to the development and progress of the textile and apparel sector in the region. It is a place where ideas become reality, where connections are forged, and where the textile industry's future is etched. Intex India 2023 is not just an exhibition; it's an experience that will shape the industry's future.

As per a OTEXA report, apparel and textile imports to the US saw a 4.5per cent decline, equivalent to 8.4 billion sq. mt. (SME), in September this year compared to 8.8 billion SME during the same period the previous year. Over the first nine months of 2023, imports recorded a significant 16.5per cent decrease, amounting to 71.0 billion SME compared to 85.0 billion SME in the corresponding period of the previous year.

Specifically, imports from China saw a 9.5per cent increase, reaching 3.3 billion SME, compared to 3.1 billion SME the previous year. In contrast, imports from Vietnam declined by 12.4per cent, equivalent to 5.41 million SME in September, compared to 6.2 million SME the previous year. Imports from Turkey increased 9.7 per cent, totaling 4.8 million SME, compared to 4.4 SME the previous year. Israel experienced a remarkable surge, with imports rising by 914per cent to 4.95 million SME in September, compared to 0.5 million SME the previous year.

However, Egypt's exports to the US saw a substantial decline of 84per cent, amounting to 1.1 million SME, compared to 6.7 million SME the previous year. Imports from Malaysia surged by 76.3per cent in September compared to the same period last year, with the country shipping 6.1 million SME, up from 3.5 million SME the previous year. Meanwhile, imports from Pakistan increased by 1.1per cent, totaling 2.7 million SME, compared to just under 2.7 million SME the previous year. Shipments from India experienced an 11per cent decline, reaching 7.1 million SME in September, compared to 8.0 million SME the previous year.

More...

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Europe’s Circular Turn: The Danish vision shaping a new industrial era

In a speech that captured both urgency and ambition, Danish MEP Rasmus Nordqvist stood before an audience of European policymakers,... Read more

“The US government’s economic data makes no sense. It’s a con.” says David Birnb…

“The US government’s economic data makes no sense. It’s a con,” declares David Birnbaum, strategic planner for the global garment... Read more

India's fiber sector spins a new thread of growth

India's clothing fiber sector is on the cusp of a revolutionary decade, moving beyond its traditional identity as a cotton... Read more

Global Supply Chain Earthquake: The 100% ‘Trump Tariff’ and the scramble for Chi…

The imposition of an additional 100% tariff on all Chinese goods by President Donald Trump—a move that underscores the fickleness... Read more

Trump's 100% Tariff on China: Why should Indian apparel exporters not view this …

The announcement by President Donald Trump to impose an additional 100% tariff on all Chinese goods, on top of existing... Read more

Yarn Expo Autumn 2025: A premier international platform for the yarn industry

Yarn Expo Autumn 2025 concluded a highly successful run, firmly establishing its position as the premier international platform for the... Read more

The Fashion Week of the Decade In Paris: A new chapter for the industry

The highly anticipated fashion week season, which came to a close recently in Paris, was not "business as usual". The... Read more

Tariffs Are Killing "Free, Open" Trade,The Human Cost of Uncertainty: …

In the intricate, interconnected world of global apparel, tariffs are not just a line item on an invoice—they are, in... Read more

China's apparel industry battles a mid-2025 contraction

The summer of 2025 brought an abrupt end to the modest recovery that China’s apparel industry experienced in the previous... Read more

Class: BlockTexx puts Australian innovation on the global sustainability map

In a landmark development for the Australian recycling sector, BlockTexx, a pioneer in textile waste recovery, has become the first... Read more