"It has been a difficult year, demand of new machines is low, will see whether ITMA has an impact,” said Dr Norbert Klapper, CEO Rieter, in the first press conference of ITMA 2019 here in Barcelona on June 20. He further added, “The year saw worsening and uncertain business environment in China, elections in India, and though the government is stable now, but remains to be seen, if in the progressive steps, is textile being included. Situation in Turkey remains the same."

“It has been a difficult year, demand of new machines is low, will see whether ITMA has an impact,” said Dr Norbert Klapper, CEO Rieter, in the first press conference of ITMA 2019 here in Barcelona on June 20. He further added, “The year saw worsening and uncertain business environment in China, elections in India, and though the government is stable now, but remains to be seen, if in the progressive steps, is textile being included. Situation in Turkey remains the same. The demand for new machines was low, customers are asking us the reason to invest and we have to see what impact ITMA brings? We expect normalization and not a big boom post ITMA as the fundamentals are not supportive.” Dr Norbert opines.

“It has been a difficult year, demand of new machines is low, will see whether ITMA has an impact,” said Dr Norbert Klapper, CEO Rieter, in the first press conference of ITMA 2019 here in Barcelona on June 20. He further added, “The year saw worsening and uncertain business environment in China, elections in India, and though the government is stable now, but remains to be seen, if in the progressive steps, is textile being included. Situation in Turkey remains the same. The demand for new machines was low, customers are asking us the reason to invest and we have to see what impact ITMA brings? We expect normalization and not a big boom post ITMA as the fundamentals are not supportive.” Dr Norbert opines.

Developments focused on recycling, shorter staple fibre spinning at Rieter

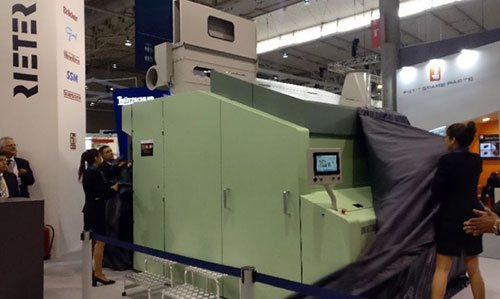

Rieter showcased innovations based on productivity, cost efficiency and flexibility in technology. The focus of many developments is spinning of low cost, short staple and waste recycling technology.

many developments is spinning of low cost, short staple and waste recycling technology.

At ITMA 2019, Rieter showcased innovations for all four spinning processes of fibre preparation, Ring and compact-spinning process and Rotor spinning process .These innovations have been designed to reduce raw material, energy and labor costs, while also increasing productivity during production of the yarn quality required in each case. Solutions also focused on to increase the flexibility of the spinning mill .

Fiber preparation

The blow room VARI Oline with the new UNI Clean B 15 brings significantimprovements in terms of energy consumption and the cleaning result for all spinningprocesses. The same applies to the new high-performance card C 80, which offersan unrivaled level of productivity.

Ring and compact-spinning process

To increase the cost effectiveness of the ring spinning and compact spinning process, Rieter reveals the new comber E90, the new roving frame F 40, the piecing robot ROBO spin and three different compacting units that can easily be installed on and removed from a ring spinning machine: COMPACT drum, COMPAC Tapron and COMPACT easy.

Rotor spinning process

Innovations that bring considerable improvements in efficiency for the rotor spinning process were also presented. The draw frame module RSB-Module 50 can be used in combination with the high-performance card C 80 and can be configured to a highly efficient direct process with the new semi-automated R 37 or the fully automated R 70. The new, cost-effective rotor spinning machines are characterized by low energy consumption, high productivity and high machine availability with low raw material costs.

ESSENTIAL – Rieter Digital Spinning Suite

The new innovations for the four spinning processes are supplemented by two new functionalities of ESSENTIAL: ESSENTIALorder and ESSENTIALconsult, which are available to all Rieter customers free of charge with the purchase of a new machine.

In addition to the existing modules ESSENTIALmonitor, ESSENTIALmaintain andESSENTIALpredict, the next steps are demonstrated: ESSENTIALlab for integrating laboratory data into the spinning mill management system, ESSENTIALoptimize, the intelligent recipe management system, and ESSENTIALautomate for integrating the transport and logistics systems.

Rieter is the world’s leading supplier of systems for short-staple fiber spinning. Based in Winterthur (Switzerland), the company develops and manufactures machinery, systems and components used to convert natural and manmade fibers and their blends into yarns. Rieter is the only supplier worldwide to cover both spinning preparation processes and all four end spinning processes currently established on the market. Furthermore, Rieter is a leader in the field of precision winding machines.With 16 manufacturing locations in ten countries, the company employs a global workforce of some 5150.