FW

The global apparel industry is a complex web of production, consumption, and trade, with Bangladesh playing an important role as a major manufacturing hub. However, the industry faces challenges, demand drip due to economic slowdown, rising labor costs, environmental concerns, and the need for greater diversification. Therefore, a partnership between India and Bangladesh, termed ‘Bangladesh+1’, holds immense potential to reshape the regional and global apparel sector.

Bangladesh's RMG sector challenges

Bangladesh's ready-made garment (RMG) industry is its economies backbone. The sector has seen remarkable growth over the past few decades. However, this success is not without challenges. The industry faces issues such as over-reliance on RMG that makes the economy vulnerable to fluctuations in global demand and competition. Concerns about worker safety, wages, and working conditions persist. Falling demand in key export markets like Europe and the US has led to lower orders this has a direct impact on Bangladesh's export earnings. Domestic inflation is also putting pressure on wages, and worker unrest is a recurring concern. Frequent power outages and rising energy costs are disrupting production and increasing operational expenses. The political dynamics also create uncertainty for businesses, affecting investment decisions.

India's strengths in raw materials, manufacturing

India on the other hand has a robust textile and apparel sector with strengths in raw materials, as India is a major producer of cotton, yarn, and fabrics, providing crucial inputs for Bangladesh's garment industry. This is a significant advantage, as Bangladesh relies heavily on imported raw materials. India has a well-established textile manufacturing base, with expertise in spinning, weaving, and processing. And India has a pool of skilled professionals in the textile and apparel sector.

The Bangladesh+1 partnership, win-win for both

A strategic partnership between India and Bangladesh can create a win-win situation for both countries. India can support Bangladesh's garment industry by supplying raw materials of high-quality. India can also collaborate with Bangladesh to improve manufacturing processes, enhance productivity, and adopt sustainable practices. Joint initiatives can focus on developing new technologies and promoting innovation in the textile and apparel sector. Closer cooperation can reduce trade barriers and encourage greater investment flows between the two countries.

Regional cooperation in the textile and apparel sector offers several benefits. By leveraging each other's strengths, India and Bangladesh can enhance their competitiveness in the global market. Collaboration can lead to greater efficiency in production, logistics, and supply chain management. Joint efforts can focus on promoting sustainable practices and reducing the environmental impact of the industry. Also, cooperation in the textile and apparel sector can contribute to broader regional integration and economic development.

The challenges facing Bangladesh's RMG sector present a unique opportunity for India. By acting as a reliable partner and simultaneously leveraging government support and schemes to strengthen its own manufacturing capabilities India can support its neighbor and significantly boost its own apparel industry. This could be a catalyst for deeper regional integration, increased raw material exports, a stronger ‘Make in India’ initiative.

India’s spinning sector plays a crucial role in the global textile value chain. With its vast production capacity, diverse product range, and competitive pricing, India has emerged a leading yarn supplier.

A spinning giant

India holds the second-largest spinning capacity globally, after China which has over 100 million spindles. In 2024, the installed spindle capacity was 52 million, a substantial contribution to the global yarn market. This vast capacity allows India to effectively serve both domestic and international demand, solidifying its position as a key player. This scale allows India to capitalize on economies of scale, contributing to its competitive pricing.

A spectrum of yarns

What works for India is the versatility of yarns tailored to diverse customer needs.

Cotton yarns: India's abundant cotton production, the third largest globally, provides a readily available raw material for its spinning mills. Cotton yarn remains a cornerstone of the industry, widely used in apparel, home textiles, and industrial fabrics.

Polyester yarns: With rising demand for synthetic textiles, polyester yarn production has seen significant growth in India. This segment is a close competitor to cotton yarn in terms of volume.

Blended yarns: Indian spinners are adept at creating blended yarns, combining different fibers like cotton and polyester, viscose, or acrylic to achieve specific properties. This segment represents a significant portion of the market, offering specialized solutions to textile manufacturers.

Recycled yarns: With growing emphasis on sustainability, recycled yarn production is gaining traction in India. Utilizing pre- and post-consumer waste, this segment offers environmentally friendly options for textile manufacturing. While still a smaller segment compared to traditional yarns, it is the fastest growing, reflecting global sustainability trends.

Weaving a winning strategy

India a major exporter of yarns, several factors contribute to India’s competitiveness globally. Cost advantage due to lower labor costs and readily available raw materials. Indian spinners have invested heavily in modern technology and quality control measures to ensure their yarns meet stringent international standards. And India's well-established textile supply chain ensures a smooth flow of raw materials and finished goods.

Fluctuating prices a challenge

One challenge is price fluctuations. Raw materials prices fluctuate significantly, impacting profits. And there is stiff competition from other yarn exporting countries. Tariffs and trade barriers of importing countries can make Indian yarn less competitive. Inefficient logistics increase transportation costs and delays, affecting competitiveness. Currency fluctuations also affect competitiveness.

Government initiatives

The Indian government recognizes the importance of the textile industry and has implemented schemes to support its growth. These include:

Production Linked Incentive (PLI) Scheme: This aims to boost domestic manufacturing and attract investments. While the initial focus was on man-made fabrics and garments, the scheme's benefits indirectly support yarn spinning by stimulating demand for domestic yarn.

Textile Parks Scheme (PM MITRA): The PM MITRA scheme aims to establish integrated textile parks with world-class infrastructure, attracting scale investments. These parks are expected to benefit the spinning industry by providing access to better infrastructure and promoting cluster development.

The fashion industry stands at a crossroads, with mounting environmental concerns and untapped economic potential. Komal Hiranandani, Director, Dolcevee, a sustainable clothing brand, highlights during a knowledge session at Bharat Tex, the burgeoning resale market as a key solution. A recent study revealed that 24 per cent of Indians have purchased pre-owned fashion, indicating a strong consumer appetite. Beyond the obvious environmental benefits, resale offers significant economic advantages. The Ellen MacArthur Foundation estimates that consumers globally lose $460 billion annually by discarding reusable clothing. Unlocking the logistics of resale is crucial to capitalizing on this lost value.

While downcycling and fiber-to-fiber recycling are important, prioritizing resale for garments with remaining life is the most economically and environmentally sound approach. The global resale market is booming, growing at an 11 per cent compound annual growth rate. Leading brands, from Gap to Gucci, are embracing resale programs, recognizing its integral role in the future of fashion.

In India, managed marketplaces, where items are quality controlled, are deemed more suitable than peer-to-peer resale. This ensures brand integrity and customer satisfaction. Furthermore, integrating resale into return processing can significantly reduce waste. Optoro's 2022 data shows that retailers in the US landfilled 9.6 million pounds of returned products. Resale offers a viable alternative, allowing returned items to be resold, either on the brand's website or through managed marketplaces, generating revenue and minimizing waste. The key lies in establishing strategic partnerships and efficient logistics to unlock the full potential of the resale revolution.

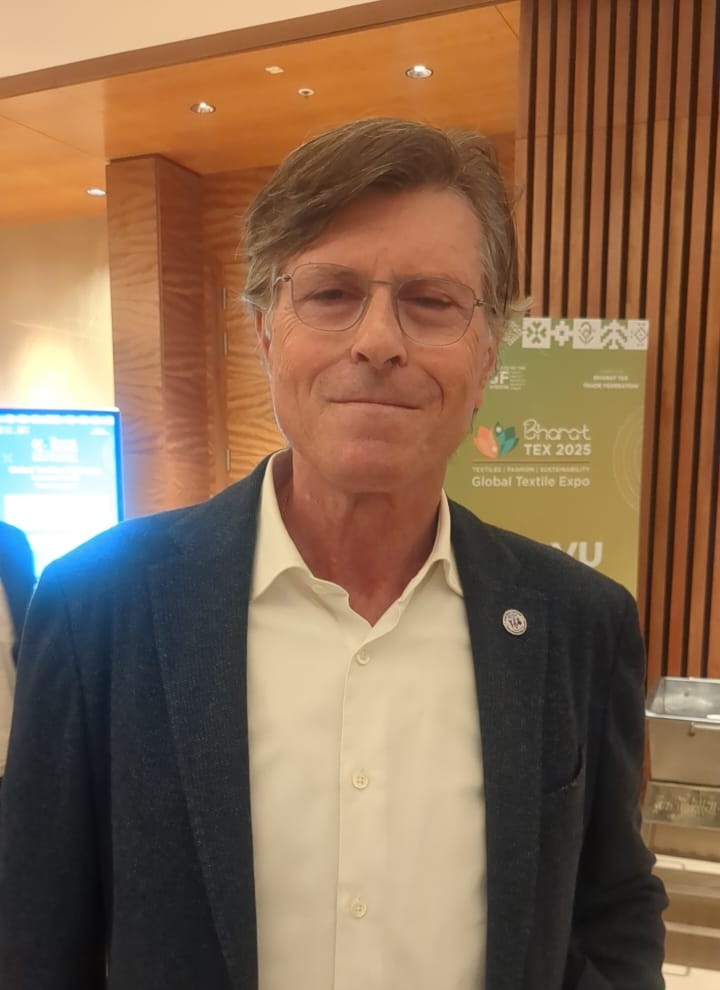

Juan Pares, soon to be President of the ITMF, was impressed by his first Bharat Tex visit. "Really, really good impression," he declared, speaking on the sidelines of a knowledge session at Bharat Tex, noting the well-organized event and the presence of key industry figures. His company, Santanderina Group, also had a strong presence and business with India.

Pares acknowledged the textile industry's challenging times, emphasizing the need for transformation. "We need to think more in margins than in volume," he stated, highlighting innovation as the key. This included innovation in products, techniques, digitalization, and even the industry's mindset. He stressed the importance of attracting young talent to the textile sector, competing with other industries like car manufacturing and digital businesses. "The key point is the talent," Pares insisted. "Human resource is the key." He linked talent to innovation, which required an open mindset.

Pares' connection with India goes back to 1986. Santanderina has a company in India, engaging in both sourcing and selling. They source garments, yarns, and fabrics, while selling protective wear and high-end fashion fabrics. They also source basic cotton fabrics, transforming them in Europe, as well as specialized yarns.

Pares sees immense potential for the Indian textile industry. He believes India needs to focus on eliminating trade barriers and negotiating better agreements with other countries to compete effectively with nations like Pakistan, Bangladesh, and China. He noted that cost isn't the only factor; developing new products and creating value are also crucial. While acknowledging India's current leadership in cotton, he pointed out the need to improve performance in polyester and polyamide to become a one-stop shop for global textile groups. He believes India has a bigger role to play, particularly by capitalizing on its strength in cotton.

The manufacturing landscape is undergoing a data-driven transformation, driven by climate change and increasing demands for sustainability. Akhil Sivanandan, CEO & Co-Founder of Green Story, a leading company in this space, while speaking in a knowledge session, highlights the importance of data capture in manufacturing. He explains how automated facilities with data capture enable faster and more cost-effective life cycle assessments and carbon footprinting. Green Story has been pioneering this approach for over a decade, helping brands understand their environmental impact through precise data analytics.

Impending regulations, particularly in Europe, are accelerating this shift. The 2027 Carbon Border Adjustment Mechanism (CBAM) will require manufacturers to provide detailed process-level information. Sivanandan emphasizes that having the right data empowers informed supply chain decisions, preventing wasteful investments in ineffective initiatives.

With growing pressure on manufacturers from investors and consumers for accountability, data mastery is no longer optional. Sivanandan believes that by harnessing data, companies can not only meet regulatory requirements but also spearhead a sustainable future. In this evolving manufacturing era, effective data capture and analysis are essential for survival and success in the green revolution.

Green Story collaborates with over 200 global brands, specializing in Product Carbon Footprint (PCF) methodologies and life cycle assessments. The integration of smart facilities enables real-time data capture, crucial for both regulatory compliance and competitive marketing. Sivanandan envisions real-time life cycle assessments as game-changers, shifting from static assessments to dynamic, actionable insights.

M Maniwanen, Chairman of Busana Apparel Group, Indonesia, envisions a textile industry where tradition and innovation intertwine. While acknowledging India's historical strength in cotton production, Maniwanen emphasizes the crucial need to embrace MMF to ensure the industry's future.

During an interview on the sidelines of Bharat Tex 2025, Maniwanen addressed the traditional divide between cotton and MMF. He pointed out the changing dynamics of the MMF market, noting that previously, a few large corporations dominated the sector. However, he sees significant opportunities arising from the Indian government's supportive policies, including incentives for land, labor, and capital, which are creating a fertile ground for smaller players and innovation. This support, he argues, is vital for the industry's evolution.

Maniwanen's vision centers on blending the inherent qualities of cotton with the advantages of MMF. He believes the future lies in creating fabrics that combine the softness and comfort of cotton with the durability and versatility of synthetic fibers. This approach, he contends, is not only about creating competitive products but also about achieving sustainability, a critical factor for the modern textile industry.

He actively fosters alliances with Indian textile manufacturers, sharing knowledge and resources to develop innovative and eco-friendly fabrics. The results of these collaborations are now visible. New collections showcase innovative designs blending cotton's rich textures with MMF's resilience.

Busana Apparel Group has emerged as a symbol of innovation, demonstrating that the future of textiles lies in embracing change, fostering collaboration, and weaving together the best of both natural and synthetic worlds.

Style Union, a rapidly expanding brand boasting over 100 stores across southern India, is a testament to the power of Indian sourcing. Mridul Tondon, who oversees buying and merchandising, emphasizes how their "Made in India" commitment has become the cornerstone of their success, during his visit at Bharat Tex as a buyer. They champion the quality, craftsmanship, and innovation India offers, showcasing it to the world. Style Union's growth is intrinsically linked to this philosophy.

The evolution of Indian retail, particularly the shift in consumer behavior among younger generations, has presented exciting opportunities. Style Union has adapted to this change, embracing boldness and experimentation while staying true to the unique Indian aesthetic. This has allowed them to leverage India's talented designers and manufacturers, fueling their rapid expansion.

Value drives the Indian market. It's not just about price; it's about quality and style. Style Union understands this. Their focus on Indian sourcing allows them to control quality and offer competitive prices, delivering true value and contributing to their growth.

Sourcing nearly 90 per cent of their products from India is more than a strategy; it's a core value. Style Union supports local artisans, manufacturers, and the Indian economy. This resonates with the growing national pride among consumers, a key factor in their expanding customer base.

India, with its vast population and burgeoning economy, has the potential to become a global retail powerhouse. Style Union is actively working to establish India as a key player on the international fashion stage.

While celebrating their successes, Style Union acknowledges challenges, such as sourcing specialized materials. They believe government support for local production and innovation is essential to develop high-quality, globally competitive sourcing within India.

Style Union, with its 100+ stores, is more than a brand; it reflects the dynamism of Indian sourcing. They are committed to showcasing Indian craftsmanship to the world, believing in the future of Indian retail and playing a role in shaping it. Their story is a testament to the power of ‘Made in India.’

RSWM’s Q3, FY25 net loss narrowed to Rs 9.23 crore as against a net loss of Rs. 34.07 crore loss in Q3, FY24. The company’s sales increased by 22.34 per cent to Rs 1195.62 crore during the quarter from Rs 977.32 crore in the corresponding quarter of the previous year.

RSWM’s revenue from the yarn segment increased to Rs 970.95 crore during the quarter as against Rs 844.12 crore in the corresponding quarter last year. Revenue from the fabric segment also increased Rs 299.68 crore from Rs 225.54 crore in the same period last year.

Flagship company of the LNJ Bhilwara Group, RSWM is a leading Indian textile manufacturer and exporter, operating for over 60 years. They produce a wide range of yarns, fabrics, and denim, exporting to over 70 countries.

Following a board meeting, the company appointed Rajeev Gupta as an Additional Director and Joint Managing Director for a three-year term, effective February 12, 2025, subject to shareholder approval. He will also serve as Key Managerial Personnel.

Trident Group, a leading home textiles conglomerate, announced a major expansion plan at Bharat Tex 2025, targeting a threefold growth of its India business by 2027. The company will invest Rs 1000 crore in FY25-26, focusing on sustainability, modernization, and asset enhancement across its home textiles, yarn, and energy businesses.

A key initiative is the launch of Luxehome by myTrident, a new luxury home textile line featuring premium bedding and towels priced between Rs 4,000 and Rs 40,000. This move positions myTrident to capture a significant share of India's growing luxury home furnishings market. myTrident also aims to expand its retail presence from 7,000 to 10,000 touch points, strengthening its domestic footprint. The brand will also target growth in the Horeca, institutional, and corporate gifting sectors, while collaborating with major e-commerce and quick commerce platforms.

Trident Group Chairman, Rajinder Gupta, emphasized the company's commitment to innovation and sustainability, highlighting India's potential as a textile powerhouse. myTrident Chairperson, Neha Gupta Bector, described Luxehome as a transformational step, bringing world-class luxury to Indian homes. myTrident CEO, Rajneesh Bhatia, outlined the brand's retail expansion plans and focus on diverse market segments.

Bharat Tex 2025 also served as the launch platform for myTrident's Spring Summer ’25 collection, inspired by India's rich textile heritage and blending traditional craftsmanship with modern techniques.

Nigeria aims to end its textile imports from China and India. As per John Enoh, Minister of State for Industry, Trade and Investment, the country plans to revive the domestic textile industry and its value chains by promoting ‘Made in Nigeria’ products. Nigeria imports textiles worth $6 billion annually form these two countries.

Enoh recently toured industries in Lagos and Ogun states, emphasizing the government's focus on economic growth through manufacturing and job creation. He cited the flourishing textile industry in neighboring Benin Republic, which targets the Nigerian market, as inspiration. He recalled a time when the Nigerian textile industry was a significant employer.