FW

Indian textile and apparel exports to Canada can double by 2020. Exporters have a huge scope for expansion and growth to fill the gaps in the Canadian textile and apparel market including its FTA partners. Indian manufacturers have a great opportunity to interact directly with Canadian buyers and fashion and apparel experts.

The total value of apparel production in Canada continues to decrease while apparel imports continue to increase. Since 2011, apparel imports have increased by 8.3 per cent annually. Between 2010 and 2014, the total number of establishments contracted by approximately 12 per cent. In 2015, approximately 20,000 employees were employed in the sector. Canada’s FTA with the United States, Mexico, Chile, Costa Rica and Honduras contain tariff preference level (TPL) provisions for certain textile and apparel goods being imported or exported within the respective free trade zones. TPL-eligible goods are goods that do not meet the requirements of the FTA Rules of Origin but can still receive the same preferential tariff treatment as goods from the country of origin, up to a negotiated quantity.

Canadian apparel and textile importers and retailers are eager to connect with the world’s major apparel and textile manufacturers. Some of Canada’s brands are Aritzia, Le Chateau, Walmart-Canada, Jockey-Canada, Gildan, Canadian Goose and Roots.

Clean Clothes Campaign works to ensure that those injured after a factory accident get the compensation they deserve. It has called upon brands to calculate and distribute payments contributed by international buyers and based on international standards.

One such tragedy the program is concerned about is the Aswad fire. Four years ago, a fire broke out at Aswad Composite Mills in Bangladesh. At least seven workers were killed and over fifty injured. Even after all this time the families and survivors still remain without full and fair compensation. Brands like H&M, C&A and Primark were sourcing from the factory.

The fire occurred in a factory that was deemed unsafe by inspectors, but which nevertheless continued to operate. It was caused by the explosion of an overheated machine on the ground floor, which set fabrics on fire, trapping workers on an upper floor. Compensation offered by the factory owner fell far below that received by victims of earlier disasters including the Tazreen factory fire and the Rana Plaza collapse.

Brands sourcing from Aswad did provide compensation but what Clean Clothes is emphatic the provision of such payments should not depend on public outrage or media interest but should come spontaneously.

Call to Action is a commitment by fashion companies to accelerate the transition to a circular fashion system. An initiative by Global Fashion Agenda, Call to Action is a counteraction to today’s linear and unsustainable take, make, dispose economic model, which sends too many garments to landfills and incinerators. The aim is to accelerate the fashion industry’s transition to a more circular system by increasing the volume of used textiles collected, reused and recycled by 2020. This includes a design strategy for cyclability by 2020, enabling re-use, upcycling and recycling.

The final list of signatories counts 64 leading fashion companies and corporations. Together, the 64 industry players represent 143 brands and a combined value of an impressive 7.5 per cent of the global fashion industry. Among the signatories are Adidas, ASOS, Bestseller, Eileen Fisher, Guess, Hugo Boss, Inditex, Lacoste, H&M, Kering, Tommy Hilfiger and VF.

The signatories have committed to defining a circular strategy for their own company by December 2017.

Global Fashion Agenda takes a central role in catalysing the various stakeholders involved in making this happen and over the next three years commits to provide the network, knowledge and advocacy to ensure that these issues are lifted, communicated and implemented in the broader industry.

From October 11 and global apparel fabrics & accessories industry will congregate in Shanghai to showcase the latest and the best trends the industry for the three-day Intertextile Shanghai Apparel Fabrics event. Shanghai will become a point of intersection between East and West. And as Wendy Wen, Senior General Manager of Messe Frankfurt (HK) explains, “Intertextile Shanghai Apparel Fabrics is first and foremost a business-focused sales platform. Nowhere else can over 4,500 quality suppliers from across the entire apparel sector be in immediate reach of buyers. And at no other event can these suppliers gain exposure to so many trade buyers from the international market. It is this unrivalled combination that creates the right conditions for business to flourish.”

As a global sourcing hub, the fair attracts buyers big and small, domestic and international. It is also a major source of inspiration for leading fashion brands which will participate in the fair’s business matching programme. This includes labels such as American Eagle Outfitters, Bestseller, C&A, Calvin Klein, E.Land, Eral, GVSSJEE, Joeone, L.L.Bean, Lily, Ports, PurCotton, Quiksilver, s.Oliver, Skechers, Trands and many more.

Autumn edition 2017 at a glance

The latest edition has a lineup of 4,538 exhibitors from 32 countries & regions, and is set to host close to 70,000+ trade buyers from 100+ countries & regions. There are country specific pavilions from France, Germany, Hong Kong, India, Japan, Korea, Milano Unica (Italy), Pakistan, Taiwan and Thailand. Chinese exhibitors are grouped by product end-use in eight halls. And there are group pavilions by Better Cotton Initiative (BCI), Button & Garment Accessories Industry Chamber, DuPont, ECOCERT, Hyosung, INVISTA, Lenzing, OEKO-TEX and more. Innovative product zones such as Accessories Vision, All about Sustainability, Beyond Denim, Functional Lab, Premium Wool Zone and Verve for Design, would enthrall the visitors. Fringe programme comprising of eight international and domestic trend forums, seven panel discussions, 30+ seminars, Digital Printing Forum and more, would keep the visitors engaged during the show. There are concurrent fairs held alongside the expo, including Yarn Expo Autumn, fashion garment fair CHIC and knitting fair PH Value to cash in on the potential.

Convergence of fashion & innovation

While an unmatched event in terms of sourcing from the entire apparel fabrics and accessories product spectrum, Intertextile Shanghai is also valued by buyers for its quality of products as well. Those looking for up-to-the-minute fashions are well served with the likes of the France and Japan Pavilions, while SalonEurope area presents the best of Europe. Cutting-edge original pattern designs can be found in Verve for Design, stylish accessories are on offer in Accessories Vision, while many new Chinese fashion brands are beginning to emerge at the fair.

The fair is also a focal point for fabric innovations. The Functional Lab is the centerpiece of the fair’s innovative offerings, there is plenty more to be discovered, especially from around the Asian region. Korea and Taiwan, in particular, are breeding grounds for textile innovation, and their pavilions will draw crowds of buyers from the first to the last minute of the fair. The Group Pavilions are a showcase of the industry’s best innovators, combined with the wide range of solutions offered by their partner mills within the pavilions. There are also many innovative products and solutions for environmental protection on offer at the fair this year, naturally in the All about Sustainability zone, but also in Accessories Vision and Beyond Denim, as well as throughout the domestic exhibitor halls.

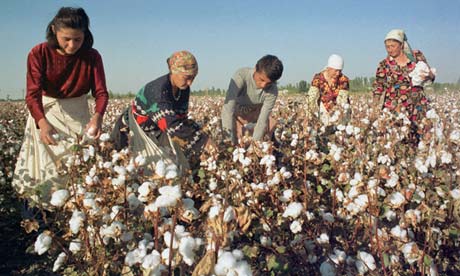

"In order to take the eco-friendly route, many leading brands from apparel industry’s and retailers need to significantly increase their uptake of ‘sustainable cotton’, says a WWF study, Pesticides Action Network (PAN) UK and Solidaridad. The report ranks apparel brands and retailers who use more than 10,000 tons of lint cotton on their use and uptake of ‘sustainable cottons’ such as organic cotton and ‘identity cottons’ such as the Better Cotton Initiative, Cotton made in Africa, Fairtrade and others."

In order to take the eco-friendly route, many leading brands from apparel industry’s and retailers need to significantly increase their uptake of ‘sustainable cotton’, says a WWF study, Pesticides Action Network (PAN) UK and Solidaridad. The report ranks apparel brands and retailers who use more than 10,000 tons of lint cotton on their use and uptake of ‘sustainable cottons’ such as organic cotton and ‘identity cottons’ such as the Better Cotton Initiative, Cotton made in Africa, Fairtrade and others.

Findings reflect Ikea, Tschibo, C&A, Marks & Spencer, and H&M are the leading brandswhen it comes to reporting sustainable cotton use. A matter of concern is that top brands such as Walmart, s.Oliver, Amazon, Footlocker and Giorgio Armani, all scored zero in the report. Of all the companies, C&A made the biggest advance in uptake almost doubling its score. In terms of policy, Gap Inc, IKEA and Marks & Spencer were making the biggest advances while in terms of traceability, M&S, C&A and H&M expanded their list of public suppliers.

A lot more needs to be done

While the results are encouraging, it also showcases a lot still needs to be achieved. Only around half of all assessed companies have a policy on sustainable cotton. While company performance on uptake and traceability is considerably low on policy. Only 11 companies have time-bound commitments or targets for greater use of sustainable cotton and uptake of sustainable cotton remains relatively low with most of the ‘heavy lifting’ being done by a handful of leaders.

The report calls for brands that use large volumes of cotton to encourage further expansion of sustainable cottons to support farmers to switch to more environmentally-friendly ways of cultivation. It says brand should set public targets for using 100 per cent sustainable cotton by 2020; adopt policies on cotton that tackle key challenges such as hazardous pesticides, water, biodiversity, labour conditions and recycling; and report transparently each year on policies, strategies and targets, as well as performance and progress.

Critics feel this is essentially a self-assessment exercise, and some brands may be tempted to put a gloss on their sourcing practices. In addition, brands regularly suggest to Ecotextile News that to improve uptake of sustainable cotton it could be that donors should stop funding more production and instead support market mechanisms and finance. For example, by providing finance that would encourage cotton traders and mills to hold sustainable cotton stocks. A common problem in uptake is when a brand finalises its collection plan, there is no cotton available as no one will hold a stock which may remain unsold, so sustainable cotton gets sold as conventional.

Bram Verkerke, Solidaridad points out donors should stop funding (the shift to) sustainable cotton production. Sustainable cotton is still only 15 per cent of global production, so this needs to grow and will require donor funding. In a context where International Development Aid is generally becoming less accessible, it remains an important mechanism of international wealth re-distribution and should continue to support the most vulnerable in the cotton sector, i.e. farmers, their families and their workers.

Besides funding, there needs to be other strong market incentives as well, in this case primarily demand from retailers and brands that traders and spinners can count on, for them to stock sustainable cotton. This too, just like improved production projects, needs to be self-sustaining after an initial investment has overcome the initial extra costs, and this will only be the case if there is a business case (i.e. demand).

Birla Cellulose has always been at the forefront of the revolution in viscose staple fibers. It charted a new course in fashion by entering the retail segment with its brand Liva. This was created in-house, and the fiber is a champion of sustainability and has created history with its fluidity and softness and versatility. Now, the company has launched an innovation called Liva Snow, which is optically white fiber. Since customers are looking at something which will make them look fresh, Birla Cellulose is planning to enter antimicrobials, which are exotic and functional based fibers.

The company caters to domestic and international textile brands such as Target and Marks & Spencer, besides its own brands like Van Heusen, Allen Solly and Louis Philippe. The company also has sub-brands called Birla Modal, Birla Viscose, Birla Spunshades and Birla Excel, among others. It has fully integrated manufacturing facilities extending from plantation to pulp to fiber in countries such as Canada, Laos, Sweden and fiber plants in China, Indonesia and Thailand.

Birla Cellulose is the fiber division of the Aditya Birla Group. In the global market, it’s working on programs with the value chain, not much with the consumer. It has newer structures and newer melanges. These are the main focus areas.

Notations, a US garment wholesaler has agreed to pay a million dollars in damages and implement measures designed to prevent future fraud by Notations or its business partners. The wholesaler repeatedly ignored warning signs that its business partner, which imported garments from China, was engaged in a scheme to underpay customs duties owed on the imported garments it sold to Notations.

Yingshun Garments, an importer of women’s apparel manufactured in China, and Import Global Designs and Olgrem, successor entities to Yingshun, engaged in a double-invoice scheme whereby Yingshun and later Import Global and Olgrem presented false and fraudulent invoices showing prices for imported garments that were discounted by 75 per cent or more for the purpose of avoiding customs duties on the garments.

Notations, which was Yingshun’s biggest customer, aided the fraudulent scheme by ignoring warning signs that Yingshun’s irregular business practices were highly suggestive of fraud. As a part of the settlement, Notations has agreed to implement a written compliance policy that will include measures to educate its employees on identifying red flags for fraud in import transactions, to monitor the conduct of its business partners who act as importers of overseas goods and to report all potentially fraudulent conduct.

US retailer Target will source 100 per cent sustainable cotton by 2022 for use in its owned and exclusive national brands in apparel and home ware. The first step will be partnering vendors to map the supply chain for each product containing cotton. This mapping will require considerable time and effort in view of the complex nature of the cotton industry. But Target believes these changes can be implemented provided that companies work with vendors to map supply chains to improve transparency.

Other measures include: using water as efficiently as possible, especially important in areas where clean water is scarce; using chemicals and other inputs as efficiently as possible; improving soil health on the land where they farm; and promoting ethical working conditions – making sure no forced labor is used during the process.

Target is recognized as a leader in innovation. It has announced the introduction of a new policy to help guide and inform other companies on how best to implement sustainable cotton programs. This sustainable cotton policy is founded in part upon the United Nations Sustainable Development Goals.

Target is an upscale discount retailer that provides high quality, on-trend merchandise at attractive prices. It has 1,816 stores in the United States.

While spinning and weaving segments of the synthetic textile industry have welcomed GST, traders in the industry are not so enthusiastic. Small and medium enterprises with an annual turnover of up to Rs 1.5 crores have been allowed to file quarterly income returns and pay tax instead of the current provision of monthly filings.

The weaving community has welcomed the tax rate revision, along with the extension of the reverse charge mechanism till March 2018. There has been a reduction in tax rates on manmade yarn from 18 per cent to 12 per cent. The GST levy on job work has been cut from 12 per cent to five per cent.

Weavers welcome the quarterly returns for entities with a turnover of up to Rs 1.5 crores but want this provision extended to the entire small and medium industry, irrespective of turnover amounts. The reduced rate of GST is expected to greatly benefit the spinning and power loom sectors, besides improving on global competitiveness and helping ensure the country’s poor are clothed at an affordable cost.

But traders say those below a turnover of Rs 2 crores have to be kept out of the tax net. There are roughly around 65,000 to 75,000 traders in the Rs 50,000 crore synthetic textile industry in Surat.

Raymond has partnered Woolmark to create a khadi wool line. The aim is to position khadi as a fashionable fabric and empower artisans in rural India. This is a first of its kind collection in pure merino wool and blended wool.

Raymond is currently working with over 20 clusters in Rajasthan and Himachal Pradesh and J&K to develop designs in pure merino wool and blended wool collections. As a part of the design intervention in more than 100 khadi clusters, Raymond also provides technical expertise to artisans to enhance product quality. The company wants to take khadi from the villages of India to international fashion ramps. The association with the Khadi and Village Industries Commission (KVIC) is expected to generate three million additional man-hours of employment for khadi artisans annually on a sustained basis.

Woolmark wants to strengthen merino wool’s position as a luxurious and versatile fiber in the market. The khadi wool collection developed with Raymond demonstrates cutting-edge innovation, comfort and is also a part of Woolmark’s Grown in Australia, Made in India effort to explore merino wool’s potential in India. Merino wool is an eco-friendly fiber with biodegradable properties.

Raymond is a worsted suiting manufacturer that offers end-to-end solutions for fabrics and garmenting. Woolmark is the global authority on wool.