Australian Wool Innovation is set to undertake a major strategic research direction change to address rapidly rising wool harvesting costs. Only about 10 per cent of AWI’s annual harvesting investment portfolio is currently spent on alternatives to manual shearing and in-shed sheep handling. Shearing costs are rising faster than efficiency gains from in-shed shearer training.

AWI also wants to use savings achieved in a recent round of staff redundancies to explore alternatives to the manual shearing of sheep. Additional research in wool harvesting could involve combining robotic, chemical and previous platforms or chain shearing technology to provide cost-saving in-shed alternatives for growers and shearers.

AWI will look at some of the industry’s bigger problems, such as the issue of shearing heavier sheep efficiently and safely. Shearing costs continue to rise while increasing numbers of growers are shearing sheep twice a year or every eight months to assist cash flow, minimise flystrike and cut crutching costs.

More than 80 potential harvesting technologies have been assessed by AWI, identifying promising areas for development including hand piece technology, parallel, modular, upright shearing platforms and alternative shearing technologies.

The aim is to find a replacement for manual shearing like robotics, laser and deal with the cost of shearing.

AWI looking at ways of cutting wool shearing costs

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

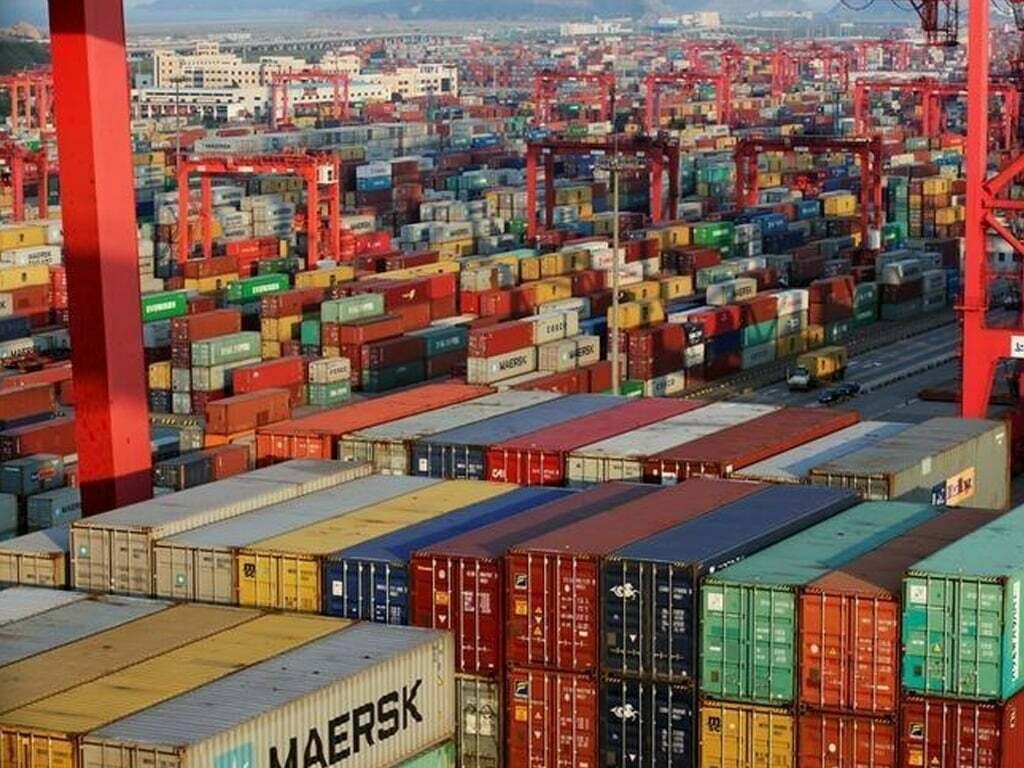

Nomura Report: Asian exporters absorb tariffs, rethink supply chains

As global trade enters a period of recalibration, Asian exporters are bearing the brunt of escalating US tariffs while simultaneously... Read more

Fashion's New Fit: Tailoring and alteration services stitch a story of growth

From the runways of Paris to the digital storefronts of global e-commerce, the fashion industry is changing. As consumers increasingly... Read more

Luxury brands swap leases for deeds as global real estate strategy shifts

Luxury fashion houses are increasingly choosing to buy, not rent, the world’s most coveted retail spaces, marking a sharp shift... Read more

STAR Network joins hands with Fashion Industry Charter for Climate Action to adv…

An inter-regional alliance of garment producer associations, The Sustainable Textiles of the Asian Region (STAR) Network, has reaffirmed its commitment... Read more

More than a lookalike, 'dupe' culture is forcing premium brands to innovate

The $4.5 trillion global luxury market is under siege, not just from the traditional counterfeiters operating in back alleys and... Read more

Recycling at Risk: How virgin polyester growth threatens fashion’s green goals

The global fashion industry is facing a sobering contradiction. Even as some of the world’s largest apparel brands proudly champion... Read more

Beyond the label, RepRisk flags human rights and environmental hazards in fashio…

The global apparel and textile industry, long celebrated for its role in democratizing fashion and creating jobs across continents, is... Read more

Made abroad, worn at home imports are replacing US garment production

The story of America’s clothing industry is one of contrast: booming demand from consumers but shrinking capacity at home to... Read more

Uniform GST rate ends duty anomalies, brings relief to textile manufacturers

When Finance Minister Nirmala Sitharaman rose to chair the latest GST Council meeting, few expected the sweeping changes that would... Read more

Renewables, recycling, and resilience, fashion’s blueprint for Net Zero

The mid-2025 stage is important. As the world inches toward 2030, the fashion industry finds itself at a crossroads between... Read more