Huntsman Corporation has entered into a definitive agreement to sell its Textile Effects division to Archroma, a portfolio company of SK Capital Partners. The total enterprise value of the transaction is approximately $718 million, which includes the assumption of approximately $125 million in net underfunded pension liabilities as of December 31, 2021. The acquisition is being partially funded with preferred equity, of which Huntsman is taking up to $80 million, an amount SK Capital Partners will seek to syndicate prior to the transaction closing.

Over the last twelve months ending June 30, 2022, the Textile Effects division reported sales of $772 million and adjusted EBITDA of $94 million. Huntsman anticipates cash taxes on the transaction of approximately $50 million. Huntsman intends to report Textile Effects as discontinued operations beginning in the third quarter of 2022. The transaction is subject to regulatory approvals and other customary closing conditions and is expected to close in the first half of 2023.

Karl Mayer Group has acquired the yarn tensioner technology from Appalachian Electronic Instruments

As per the agreement, the Karl Mayer Group will take over the complete range of products YTC (YTC-2000 AND YTC-2000 MAX) and the complete technology of yarn tensioners for weaving and warp knitting preparation from AEI. The after sales service for the installed base machines will be taken over by Karl Mayer effective from September 01, 2022. AEI will continue to support Karl Mayer and the customers during the transition. As market leader and full range supplier in indigo dyeing, the Karl Mayer Group will complete their yarn tensioner product range with this integration of the YTC technology.

Since patenting the first electronic disk tensioner in 1979 AEI has been a pioneer and leading supplier of yarn tensioners for denim and warp knitting applications. After 43 years, AEI has made the decision to exit the tension control market and focus on its patented broken and tight yarn monitoring technology.

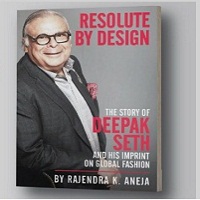

Celebrating the release of the book, ‘Resolute By Design,’ Rajeev Masand, President, Clothing Manufacturers Association of India (CMAI) felicitated its author Deepak Seth, Chairman, Pearl Group of Companies for his tremendous growth from a small time garments exporter to a global conglomerate spanning over 22 countries and production facilities across the world.

Celebrating the release of the book, ‘Resolute By Design,’ Rajeev Masand, President, Clothing Manufacturers Association of India (CMAI) felicitated its author Deepak Seth, Chairman, Pearl Group of Companies for his tremendous growth from a small time garments exporter to a global conglomerate spanning over 22 countries and production facilities across the world.

The book has been written by journalist Rajendra K Aneja based on the experiences shared by Deepak Seth.

Expanding group operations

A non-executive chairman of Pearl Global, the listed subsidiary of the company, Seth has over 31 years experience in the apparel industry. He has been responsible for expanding the group’s operations to 12 countries across the world including Hong Kong, Bangladesh and China. Seth also set up Pearl Group’s new manufacturing units in Bangladesh and Indonesia besides acquiring existing businesses in the US. He was a member of the Apparel Export Promotion Council from 1990 -1993 and was inducted as the Executive Committee as a special invitee.

Starting operations with a small order of 6,000 pieces in 1976, the Pearl Group has since grown into a global conglomerate shipping over one million garments every day. The group’s current turnover is $1.5 billion (Rs 12,000 crore) which it aims to increase to $2.00 billion in the next three years. Its achievements remain unparalleled amongst Indian garment companies.

Business acumen an inspiration

Attended by CMAI members, the felicitation program included narration of stories and anecdotes from Seth’s 45-year journey in the industry. It focused on the lessons learnt by Seth over the years. The event was a commemoration of Seth’s single-minded focus on his goals, his untiring efforts, initiatives to improve workers’ productivity and his instillation of trust, transparency, equity and ethics in his company’s operations.

The felicitation program also included an informal interaction between Seth and Rahul Mehta, Chief Mentor, CMAI, both alumni of the Jamnalal Bajaj Institute of Management.

Interesting ‘takeaways’ of the interaction

Few of the interesting points that were discussed during the informal interaction of Deepak Seth with Rahul Mehta like Seth feels that benchmark or cut off point of an entrepreneurship could be perhaps around 500 machine capacity as it is possible to manage personally but above that capacity one should ideally look at engagement of the professionals to have a stable growth.

Seth explained that he has always been very keen on looking out for any opportunities of partnership where they could improve including investing in any startups if useful technology is involved.

Talking about productivity of the workers, Seth observes that culture everywhere is different but workers are the same but it is how we train them and how we take work from them. He feels supervisors and middle management is week in India, in south there’s no hunger for overtime whereas in north the migration workers work slowly during daytime to get overtime. If you set up the right team of supervisors and middle management, Indian work force is also not bad. On the other hand, Bangladesh workers are very committed; they work for 12 hours/day, hungry to do overtime. In our Vietnamese factory for our factory of 1000 machines, we manage with only 1500 work force, whereas we may need 2000 or 2500 people here in India, there’s no alteration or defect there’s no quality issues for the products cut, manufactured and packed in our Vietnam factory. The workers there are quite educated and feel guilty if fault is found. In Indonesia, we make very high quality garments.

The interaction highlighted the management philosophy of Pearl Group’s organizational culture and business philosophy that has inspired the Harvard School of Business to study it as a case study.

Singapore-based greentech manufacturing firm Royal Golden Eagle (RGE) plans to launch a sustainable textile research center in partnership with Nanyang Technological University (NTU).

Called RGE-NTU SusTex, the centreaims to boost innovation in textile recycling and apply research outcomes to solve real-world problems. It will focus on four main areas: sustainable textile recycling, automated textile waste sorting systems, eco-friendly dye removal, and new textile development.

Researchers at the S$6 million ($4.3 million) joint center will study the chemical makeup of various textile materials to develop processes and solutions needed for a circular textile economy.

Established in 1973, RGE is a producer of sustainable natural fibers, edible oils, green packaging, and clean natural gas. The company has total assets of over US$25 billion and employs 60,000 staff across Asia, Europe, and the Americas.

According to the Vietnam Textile and Apparel Association (VITAS), the country’s textile exports grew by 17.7 per cent to $22.3 billion in the first six months of the year.

The after-tax profit of Vietnam National Textile and Garment Group (Vinatex) grew by 49 per cent to VNĐ573 billion Q2.

The firm attributed the rise in profit to its high volume of cotton in storage, which resulted in low production costs amid mounting cotton prices.

The revenues and after-tax profits of TNG Investment and Trading JSC grew by 35.7 per cent and 42.3 per cent to VNĐ2 trillion and VNĐ87 billion, respectively.

The PhongPhú Corporation raked in over VNĐ160 billion in profit, surpassing the figure in Q2/2021 by 11 per cent.

Although many firms were riding high in the second quarter, some others saw their profits eroded by rising costs.

The ThànhCông Textile Garment Investment Trading JSC earned just VNĐ55 billion in Q2, down 6 per cent against Q2/2021. The company said higher overheads and exchange rate fluctuations cost it over VNĐ75 billion, eating into its profits.

Century Synthetic Fiber Corporation’s profits fell by 2 per cent in profit due to soaring financial costs. The costs ballooned from VNĐ320 million to over VNĐ15 billion, driving its profits down to VNĐ69.4 billion.

The Hanoi Textile Garment JSC ran unprofitably as it incurred higher financial costs and elevated costs of sales. It made a loss of VNĐ5.4 billion in Q2, a stark contrast to the profit of VNĐ6.2 billion in the same period last year.

According to VITAS, the outlook of Vietnamese textiles is not very optimistic in the second half of the year as the risk of COVID-19 resurgence is still high.

On top of that, many of Việt Nam's commercial partners have been tightening up their preventive measures against COVID-19, fuelling the situation, it adds.

Levi Strauss & Co has collaborated with TGW Logistic Group to design, engineer and implement its 1.6 million square-foot highly automated omnichannel distribution center that would be capable of serving all distribution channels from a single location.

The project is split into two phases. In the first phase, scheduled to go live by April, 2024, Levi Strauss aims to achieve a throughput of up to 33 million units per year. In the second phase of the project, additional storage capacity and picking work stations will grow that number to 55 million annually.

At point of receipt, Levi Strauss receives cartons from its international production sites, as well as returned items. After inspection and repackaging, returned goods are placed into an empty mixed container that is then stored in an eight-aisle shuttle system with more than 170,000 storage locations. Up to 70% of the incoming cartons will be reused later as order cartons, saving money and reducing waste. An innovative robotic system by TGW automatically repacks the cartons into totes.

New items move from receiving to storage in either an automatic mini-load warehouse or in a shuttle warehouse with a total of 1.3 million storage locations. The mini-load facility has two functions: it’s both the supply storage for the shuttle system and the buffer storage for ready-to-ship cartons, which are directly forwarded to the shipping area via a cross-docking process.

Vietnam hopes to clock $45.70 billion export turnover in garment and textile sector during 2022, as stated by the General Department of Vietnam Customs.

As of mid-July, the country posted a 19.70 per cent Y-o-Y rise in garment and textile exports to $20.40 billion.

Its value of garment and textile exports increased by over $1 billion, according to the authority.The customs further added that around 14,000 businesses are operating in the sector, with combined capital of over US $ 46 billion, employing about 200,000 laborers.

Vietnamese garment and textile products are shipped to 55 countries and territories worldwide, including 17 markets with a turnover of more than US $ 100 million each.

Earlier, the Vietnam Textile & Apparel Association said textile and garment producers target to earn up to $21 billion from exports in the second half of 2022, raising total shipments of the year to around US $ 42-43 billion.

The Lycra Company has partnered with Browzwear, a pioneer of 3D software for the apparel industry. The new partnership will allow customers to digitally create activewear, denim, swimwear, ready-to-wear and intimate-apparel fashions that include Lycra fibers and can be sourced directly from one of 15 global mills.

Lycra will be incorporated into the platform with a special section where designers will be able to choose from a vast certified fabric library to build avatars. The collaboration will further evolve into more knowledge sharing and things that it can develop together to combine Lycra’s science of fit with their science of 3D visualization, says Julian Born, CEO, Lycra.

Creating digital garments via Browzwear streamlines the production process and reduces the need to manufacture samples, saving time and reducing waste for more-efficient and sustainable operations. When paired with fibers that are designed to increase durability and garment life, Lycra states, the partnership will have an outsized impact on elevating the fashion industry’s sustainability efforts.

Founded in 1999, Browzwear is a pioneer in digital solutions for the fashion industry. For technical designers and patternmakers, Browzwear rapidly fits graded garments with accurate, true-motion material replication, while Browzwear’s Tech Pack provides manufacturers with the tools they need to produce physical garments perfectly the first time and at every step from design to production. The goal is to help apparel companies sell more while manufacturing less, increasing both ecologic and economic sustainability.

Japan's textile and apparel imports grew by 8.8 per cent Y-o-Y but declined by 3.7 per cent M-o-M to 209 kt in June. As per a CCF Group report, imports from China surged by 9.3 per cent from the same period last year but declined by 4.1 per cent compared to last month. Japan’s textile and apparel imports during January-June surged by 1.3 per cent to 1,271ktfrom the same period last year and by 10.7 per cent compared with the same period in 2019. Japan's imports in June totaled 331.7billion yen, among which apparel imports grew by 30 per cent last year to 217.8billion yen.

Japan's textile and apparel imports grew by 31.6 per cent in June, a high level even in the same period of previous years.

This year, the proportion of Japan's textile and apparel imported from China maintained at around 56.5 per cent in last two months, which is stable in general.

The global denim market is expected to grow at a rate of 6.7 per centCAGR in the forecast period of 2022 to 2029. The rise in the consumer disposable income levels is escalating the growth of denim market.

The size of the global denim jeans market size is projected to reach $88.1 billion by 2030, growing at a CAGR of 4.2 per cent from 2021 to 2030.Rise in spending capacity, per capita consumption of the denim jeans, consciousness regarding the cloths suitable for the body types and acceptance for casual wears for office work is likely to garner the growth of the denim jeans market. In addition, increase in disposable income in the developing countries of Asia-Pacific, such as India and China, has increased the expenditure on personal grooming and clothing, which further drives the growth of the global denim jeans market share, according to Allied Market Research.

With the demand of denim continuing to grow, the annual global production of denim is 15 billion metres with half of the production coming from Asian countries like China, India, Turkey, Pakistan and Bangladesh. China is the largest exporter of denim accounting for around 64 per cent of the world’s total, followed by Pakistan, says Jitender Kumar, Vice President – Raw Materials (Fibres), Sutlej Textiles & Industries. He adds, recycling and embedding circularity in denim is adding a unique sustainability punch to this most popular attire.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

US Cotton: Shifting dynamics amidst reciprocal tariffs and quality advantages

The US has long held a dominant position in the global cotton market, thanks to its reputation for producing high-quality... Read more

India’s textile and apparel industry sees mixed fortunes in FY25: Wazir Indices

India’s textile and apparel sector showed mixed results in FY25, with growth momentum visible in sales but profit metrics showing... Read more

UK charts course for circular fashion leadership with new CFIN roadmap

A new landmark report released by the Circular Fashion Innovation Network (CFIN) outlines major strides and a comprehensive roadmap for... Read more

The Unseen Cost of Fashion Returns: Undermining sustainability efforts

Fashion brands are increasingly vocal about their commitment to sustainability, proudly unveiling initiatives centered on recycled polyester, reduced water consumption... Read more

China's Luxury Crossroads: Consolidation or retreat for global giants?

For years, China has been the undisputed El Dorado for global fashion and luxury brands. A growing middle class, with... Read more

Fashion for Good and Arvind unveil Future Forward Factories in India to cut text…

Fashion for Good and Arvind Limited have launched the Future Forward Factories India initiative, a major push to reshape the... Read more

The Scope 3 Challenge: Unpacking the elephant in the emissions room

In the escalating global focus on combating climate change, businesses are under pressure to account for their carbon footprint. While... Read more

Right Size, Right Impact: Personalized fit weaving a sustainable future for fash…

With growing environmental consciousness, the fashion industry, long criticized for its detrimental impact, is looking for new and innovative ways... Read more

From Runway to Retail Shelf: Why fashion needs a dose of FMCG discipline

The fashion industry, often lauded for its artistry and emotional appeal, stands at an intriguing crossroads. While it captivates with... Read more

Global Sourcing Expo spotlights Australia's sustainable fashion growth amid supp…

Australia's demand for sustainable fashion is reaching new heights, driven by increasing consumer awareness and a rising wave of conscious... Read more