The government of Bangladesh has set April 2018 as the deadline for completing remediation works in readymade garment factories inspected under the joint initiative of Bangladesh government and the International Labour Organisation. The Department of Inspection for Factories and Establishments (DIFE) recently started holding meetings with factory owners on evaluation progress and demanded a removal of all the safety faults in their units by April 2018.

DIFE inspector general Md Shamsuzzaman Bhuiyan said, they are holding meetings with the factories housed in their own buildings to evaluate remediation progress and the factory authorities have been asked to complete remediation by April 2018. He threatened owners if any factory inspected under ILO supported national initiative failed to fix all faults by the set deadline, they would have to face legal action. He further announced the DIFE would not permit renewal of licence for noncompliant RMG units after the deadline.

As per DIFE statistics, around 1,549 garment factories, which remained outside the purview of the inspection conducted by two buyers’ groups Accords and Alliance had been inspected under the national initiative. Post completion of initial inspection in November 2015, factories registered about 20 per cent progress in remediation in last two years.

DIFE inspector general said of the 1,590 factories, inspected under the national initiative, 513 have been closed, 64 relocated to new buildings, 14 located in economic zone areas and 178 factories added to the list of global buyers’ platform — Accord and Alliance. Currently they are monitoring remediation work in 780 factories under the government initiative. Of these 312 factories are housed in their own buildings while 468 housed in shared and rented buildings. The labour ministry would convene a meeting of National Tripartite Committee to discuss ways to punish non-compliant factories post the remediation deadline.

Apparel exporters gained over others in the segment during the September quarter (Q2) of this fiscal. Fabric and garment maker Raymond recorded profit of Rs 62 crore when compared to a net loss of Rs 7 crore in the pre GST quarter of April-June. KPR Mill, Kitex Garments and Gokaldas Exports, for which exports are the mainstay of business, saw revenue or profit either improving or steady over both the June quarter (Q1), pre GST rollout and Q2 a year before.

On the other hand Arvind, whose garmenting business is equally focused on the domestic market, saw the impact of GST rollout of 28 per cent on branded apparel with their Q2 bottom line fallng over Q1 this year. Analysts report was a marginal reduction in domestic demand in the month post GST rollout, despite a slight growth in exports. For instance, KPR Mill saw its garment production increase year-on-year from 30.48 million units in Q2 last year to 39.41 mn this year.

Prashant Agarwal, Joint Managing Director, Wazir Advisors points out overall apparel export from India to the US grew six per cent in Q2 as against the previous year's Q2, however, for overall top textile players, consolidated sales declined by five per cent and Ebitda margins declined by an average of four per cent. Further, Ebitda margin remained the same or declined for most companies. A rise in net profit of some, according to Wazir Advisors, such as Raymond, Kitex and Gokaldas Exports, was primarily due to higher other income.

Arvind’s Jayesh Shah, Chief Financial Officer, feels second quarter turned out to be another challenging one for the industry, with GST implementation impacting our domestic textile business. Even consumer-facing brands business was impacted in July as both wholesale and retail channels were under pressure. However, the brands business saw strong performance in August and September leading to good growth overall. Going forward, they expect the transition impact of GST to settle and revenue growth to return to normalcy.

Under its new multiproduct branding strategy, Baba Ramdev has now lined up Patanjali Textiles. The Bodoland Territorial Autonomous Council (BTC) authority in Assam has gone out of its way to help Patanjali, the Indian FMCG company, to set up its textile unit in Assam to produce a variety of textile fabric. This was announced by Patanjali’s promoter Ramdev at Kokrajhar in western Assam where he inaugurated a three-day yoga therapy and meditation camp in the presence of hundreds of participants.

Patanjali Ayurved, has started commercial production at its newly-set up factory at Balipara in Sonitpur district of Assam earlier this year. The land for the unit was provided by the Assam government on lease to Patanjali at a cost of Rs 13.82 crore. The factory was completed within five months. He now plans to set up about 75 units with an investment of Rs 6,000 crore. The manufacturing area is spread over 450 bighas of land.

Patanjali’s venture in the Bodoland areas will facilitate development and creation of employment opportunities in the area. It is expected that direct employment opportunities will be created for more than 5,000 people in the industrial units, while capacity production target valued at Rs 1 lakh crore is forecast for the next five years.

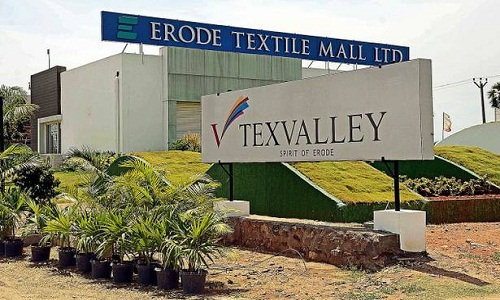

Avers D.P.Kumar, Executive Director TEXVALLEY that we deliver the results, not promisses, that will take our business associates/ patrons business and investment to the next level. While participating here in yfa trade show 2017 to promote & propagate this 'Textile Market' where the overarching theme is "The only textile market which will bring all categories of buyer network to your business place". The management is of firm belief that any textile products can be showcased and marketed here to reach out domestic, national & international buyers. The management is trying to project this concept as INDIA's regional gateway for Indian cotton textile sourcing. Also this framework supports and creates the opportunity for forwarding integration in the textile ecosystem. Texvalley Ecosystem boasts of offering 360 degree solutions to the textile world at large.

A quick glimpse of the available resources and infrastructure reassures its primacy both in terms of its strategic location within Indian Textile & Apparel business hub & instrinsically its robust business model (Texvalley is formulated under "Public-Private Partnership framework").

As we write it is a well rounded 'Product Based Zone & Selling Platform'. Says Kumar Texvalley is not only an excellent place for textile business but also offers a prime investment opportunity with the promise of high returns. And as a testimony It already has an envious list of brands available at Texvalley.

As we are seriously committed to promote it through multi modal channels. As a matter of fact the management is comprehensively looking into the factors that can contribute to increase the business and profits of all our stakeholders to really make it a wholesome business success.

Uzbekistan, the world's fifth-largest cotton producer will supply textile products worth $70 million to South Korea till the end of 2018. Relevant agreements were reached during the negotiations of the Uzbekengilsanoat delegation with leaders of the major Korean trading companies Posco Daewoo, Color Paradise, Solsang International Corp, Ratel E & T Co, , Korea Factory and Lotte Mart retail network. During the meeting with the leadership of the Korean International Trade Association (KITA) and the national electronic trading platform (KTNET), agreements on joint activities to promote Uzbek textile products in Korea in 2017-18 through the electronic trading platform KOREA Trade, including providing services through representations of Uzbek companies in Korea or Korean importers and transport companies for electronic customs clearance were signed.

Since the beginning of the year, various textile semi-finished and other products valued at $23.4 million were exported to the Korean market. Further, a supply of knitted goods to the Lotte Mart retail networks, dyed and mélange yarn for manufacturers of knitted goods from Korea was launched this year. Uzbekistan is expected to achieve full processing of cotton fibre in 2021. By 2020, the capacity of local enterprises will ensure the full processing of cotton produced in Uzbekistan, which can lead to a significant decrease in export supplies of this crop. Only in 2017, the country intends to bring internal processing of cotton fibre to 70 per cent.

At the same time, by 2021 production of textile and clothing and knitted products will increase by 2.2 times compared to 2016, including ready-made fabrics - 2.7 times, knitted fabrics - 3 times, knitted goods – 3.4 times, hosiery – 3.7 times. It is planned to double the export of products. One of the priorities of Uzbekistan, the world’s fifth-largest cotton exporter, is further development of its textile industry. Annually, the country grows about 3.5 million tons of raw cotton, produces 1.1 million tons of cotton fibre.

Since the early 90’s when NAFTA and the WTO came into existence, the apparel industry in the US has been one of the hardest hit losing about 85 per cent jobs to competition abroad. Denim and jeans, as inseparable as a horse and carriage, have been an American icon for more than a century. Earlier, there were hundreds of mills manufacturing denim and now there are just two denim plants and, what is worse, 98 per cent of the apparel purchased in the US is manufactured abroad.

The unkindest cut of all is that the iconic Cone Denim White Oak plant in Greensboro, NC which will be closing by the end of this year. One is sure that the US President will not be happy to hear this news. The plant opened in 1905 and quickly became the world’s largest producer of selvedge denim manufacturing 1.6 million square feet during its heyday. And Michael Williams of men’s wear site ‘A Continuous Lean’ says it’s a national tragedy. The mill represents tradition, pride and the expertise that gets woven into some of the world’s most revered fabrics. History can’t be rewritten, and when the plant closes Americans will have lost yet another piece of our national identity.

It’s not that the US can’t compete with other countries when it comes to quality and productivity, what the country is competing against is cheap slave labour (sweatshops); poor environmental regulations; countries that just dump their waste into drinking water supplies; and countries like Bangladesh that pays its employees $68 a month. It’s distressing to note that now ‘Made in America’ is going to cost more.

Rural Electrification Corporation (RECL), sponsored under its CSR, the training of 540 candidates belonging to SCs, STs backward classes, physically handicapped, minority, general (economically weaker) and other segments of society in longer-duration (6 months -720 hrs.) courses in production supervisor-sewing/apparel pattern making, basic course. The course was conducted by Apparel Training and Design Centre (ATDC), the largest vocational training provider in the apparel sector with over 200 ATDC centres across 23 states, 86 cities and 150 districts.

The ATDC which conducts employment linked vocational training programs to provide trained workforce to the apparel industry has since 1996 trained over 3 lakh candidates, including over 2 lakh candidates under Integrated Skill Development Scheme (ISDS) of the Ministry of Textiles, Govt. of India, thus providing placement mostly in export units. More than 80 per cent of candidates are women. Over 72 per cent of the trained candidates have been gainfully employed in the apparel sector.

Speaking on the occasion Darlie O Koshy, DG&CEO, ATDC thanked RECL for reposing confidence in ATDC to implement CSR initiative of RECL. He stated that ATDCs endeavour of providing skills to the youth of disadvantaged section of society are fully supported by AEPCs over 8,000 registered exporters by gainfully employing the ATDC trained candidates in various garment factories in most apparel clusters in the country.

Koshy further stated there are numerous success stories and many ATDC trained candidates have reached the position of factory head in many garment factories. With the quality of training provided by ATDC and 3rd party Assessment and Certification by NSDC (MSD&E, GOI) nominated AMH-SSC, trained candidates are getting employment in the apparel sector not only in India but also overseas.

Members and guests of the Southern Textile Association (STA) heard a variety of presentations during their recent Northern and Southern Division Fall Meetings in the US. Mary Lynn Landgraf, Senior International Trade Specialist, Office of Textiles and Apparel (OTEXA) in the US Department of Commerce, said the industry has an image problem in many ways, but letting people know that it’s a dynamic, growing industry is critical. Revealing data on buying attitudes toward American-made products, Landgraf said more than 80 per cent of Americans and a ‘surprising’ 61 per cent of Chinese say they would pay a premium for American-made goods in comparison to products made in China, according to a survey by Boston Consulting Group. She also shared a number of other surveys supporting this.

She said reshoring is real, based on OTEXA data, she added. The office tracks: 1) Who is coming back to the U.S, and why? and 2) Foreign Direct Investment (FDI). And the tides have begun to turn, she added. FDI has grown since 2014 and manufacturing innovation institutes have been created in the US. She also cited several factors that are driving industry back to the US., including: higher product quality and consistency; rising offshore wages; a skilled workforce; no issues with child labour; freight costs; shorter lead times; lower energy costs; minimal intellectual property and regulatory compliance risks; improved innovation and product differentiation.

Japanese used-clothing retailers are looking at enhancing exports in Southeast Asia. These retailers purchase unneeded clothes from consumers and resell them at their stores — which used to be mainly in Japan. Today they have seen that Southeast Asian markets are eagerly waiting to lap up used clothing. The Japan discards/burns around 1 million tonnes of clothes annually, however, by ensuring new markets, the efforts to encourage reuse of what would eventually be thrown away helps reduce environment pollution.

Don Don Up, a second-hand clothing store chain located in the Iwate Prefecture in Northern Japan, launched its Dondondown on Wednesday store in the Cambodian capital of Phnom Penh in 2014. It now operates 12 stores in Cambodia aiming to increase it to around 50 by 2021. The retailer also plans to expand its footprint into Thailand, Vietnam and other countries in the region.

Don Don Up’s President Akifumi Okamoto says most people in Cambodia, even those who are strapped for cash, have smartphones, they now have access to sufficient information and have become conscious about what they wear and how they wear it. International fast-fashion brands are hardly seen in the country. This is another reason for the Japanese retailer to expand its footprint in this market where there is a rising demand for used clothing.

The retailer's policy is to ‘buy anything, other than underwear.’ At its 51 stores across Japan, the retailer never refuses to buy clothes brought in by consumers, even those other second-hand retailers would not accept, such as heavily damaged or stained items, as well as clothing with personal names marked on them. For ordinary clothing, Don Don Up pays up to 500 yen ($4.42) per kilogram. Branded clothing are priced separately. The retailer picks what it wants to resell in Japan. The rest are sent to its overseas outlets. Some of them are remade into different items. Don Don Up exported 2,865 tons of used clothing in the year through September. Treasure Factory, another second-hand retail clothing shop in Japan, now sells such used items in Thailand. In a smart move, the retailer's Thai outlet buys second-hand clothes locally and resells them to consumers there.

The Nigerian Textile Manufacturing Association (MTMA) lobbied for a ban on export of cotton from the country. MTMA’s Acting Director-General, Hamman Kwajaffa, points out such restriction was required as locally produced cottons are just enough for manufacturers of textile materials in the country. Kwajaffa spoke at a public hearing organised by the Abubakar Moriki led House of Representatives committee on industry considering a Bill for an Act to establish the national cotton, textile and garment (CTG) development council and standardization in CTG value chain and ways to achieving CTG self sufficiency in Nigeria.

Kwajaffa described the move to establish the CTG development council as a step in the right direction since it would create a suitable environment for the economy to grow. Stakeholders in the garment industry have welcomed the plan to establish CTG, as it would boost cotton production in the country.

Decrying the reliance on imported fabrics by Nigerians, she said it was unfortunate that Nigeria is yet to reap the benefits derivable from the African Growth Opportunities Act (AGOA) due to the reverses suffered by the textile and garment sector of the economy over the years.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

Cotton at a Crossroads: Geopolitics, trade shifts, and the global balancing act

The global cotton market in 2025 is passing through a period of shifting trade relationships, geopolitical tensions, and the rising... Read more

German textile and fashion industry grapples with persistent economic headwinds

The German textile and fashion industry continues to pass through a challenging economic situation. An anticipated recovery remains elusive amidst... Read more

French consumers blinded by fast fashion's allure: Study

A recent study on French consumer habits in the fashion industry throws up a concerning picture, suggesting that the allure... Read more

The great retail shift in the US, private labels emerge as new brand leaders

Once a humble alternative for budget-conscious shoppers, private labels often called store brands have stealthily evolved into a commanding force... Read more

Indian textile sector braces for increased Chinese imports amid diplomatic thaw

Following high-level diplomatic engagements between Indian External Affairs Minister S. Jaishankar and Chinese Foreign Minister Wang Yi, a new chapter... Read more

The stretch revolution, spandex redefining fabric weight and cost

The addition of spandex yarn in the textile industry has changed the sector in many ways. While traditional metrics like... Read more

Weaving Relief: India's cotton duty suspension a lifeline for textile industry a…

In a move that has sent a wave of optimism through its embattled textile sector, the Indian government has temporarily... Read more

From Paris to Panipat: Can India help solve Europe’s textile recycling crisis?

In the quiet warehouses of northern France, bales of discarded jeans, shirts, and dresses pile higher each week. For French... Read more

Centrestage celebrates a decade of global fashion in Hong Kong

The Hong Kong Trade Development Council (HKTDC) will host the 10th edition Asia’s premier fashion gala – Centrestage in partnership... Read more

India, China, and Brazil to lead global cotton market in 2025-26, says ICAC proj…

As per the August 2025 ‘Cotton This Month’ report by the International Cotton Advisory Committee (ICAC), global cotton production is... Read more