UBC Okanagan, based in Canada, is working to solve the issue of wrinkling when it comes to making textile composites.

Researchers investigated several de-wrinkling methods and discovered they could improve their effectiveness by pulling the materials in two directions simultaneously during the manufacturing process. They did this by creating a custom-made biaxial fixture -- a clamp that stretches the textile taut and removes unwanted bumps and folds.

Textile composites are known for their strength and durability. But a simple wrinkle in the manufacturing process can significantly alter the end product -- sometimes diminishing its strength by 50 per cent.

Wrinkling is one of the most common flaws in textile composites, which are widely used for prototypes, as well as mass production within prominent aerospace, energy, automotive and marine applications.

The challenge was to avoid unwanted fiber misalignment or fiber rupture while capturing the out-of-plane wrinkles. Manufacturers who use these types of composites are looking for more information about their mechanical behavior, especially under combined loading scenarios.

The research included stretching the material and then using specialized image processing and 3D scanning to analyze the required forces and its impact on the wrinkling and de-wrinkling of the material.

Composite textiles are changing the way products are designed and built in advanced manufacturing sectors.

Tackling wrinkling in composites

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

From Smart Factory to Smart Business: How AI in 2026 is transforming T&A fac…

The next feature, we present as part of our year-end series, 'Wrap Up 2025, Outlook 2026', as the global textile... Read more

Paperless or Powerless: Regulations as the new 'Digital Non-Tariff Barrier' defi…

As we present this feature as part of our year-end series, 'Wrap Up 2025, Outlook 2026', the global textile and... Read more

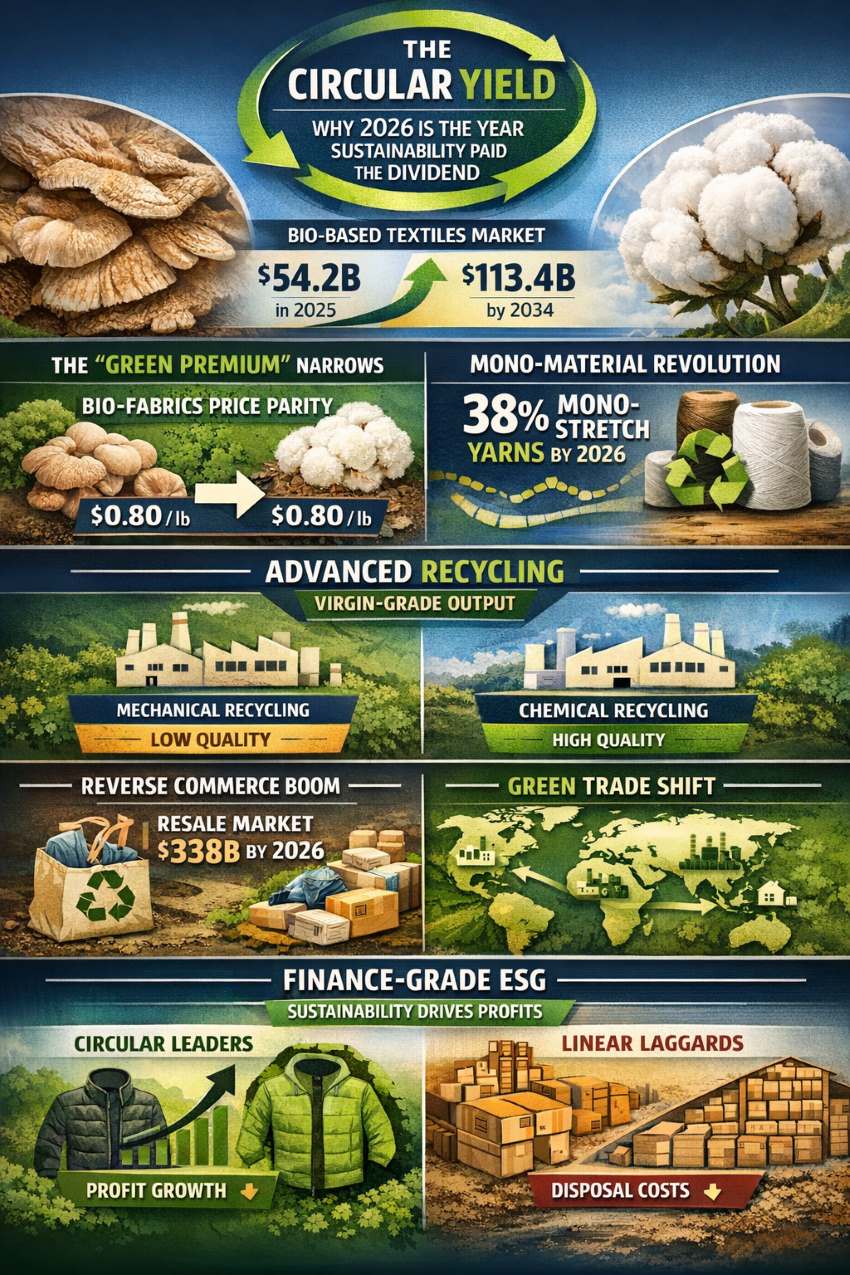

The Circular Yield Why 2026 is the year sustainability paid the dividend

As the global textile industry moves through the final quarter of the year, this feature serves as a cornerstone of... Read more

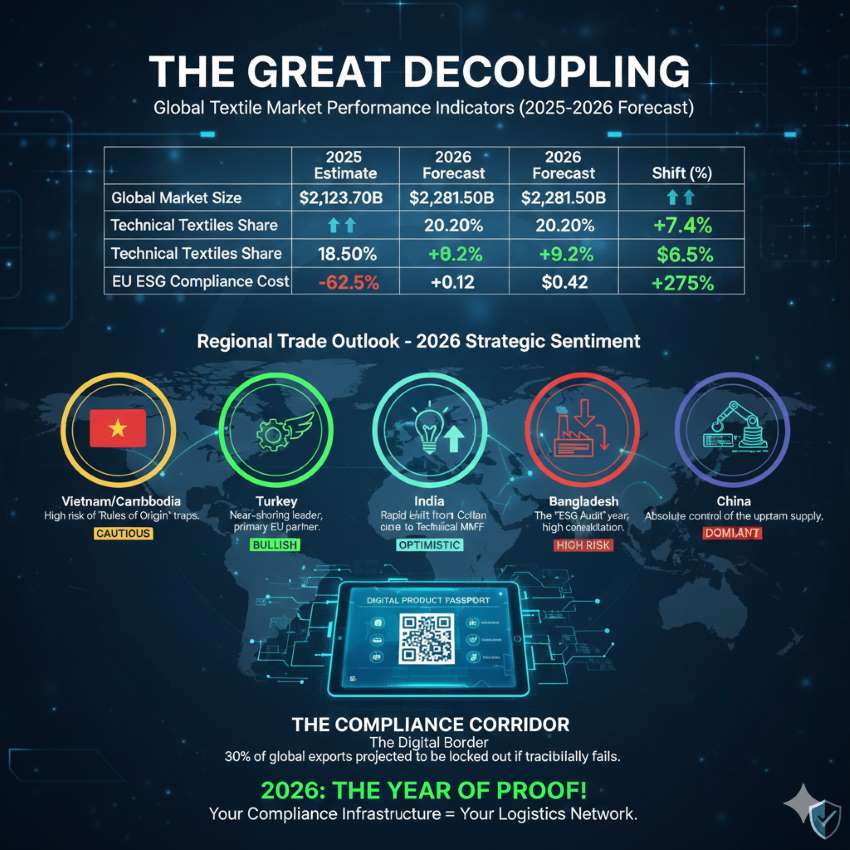

The Great Decoupling: The global play and regional and country trade outlook

This feature marks the second article in our exclusive series, "Wrap Up 2025 | Outlook 2026," where we dissect the... Read more

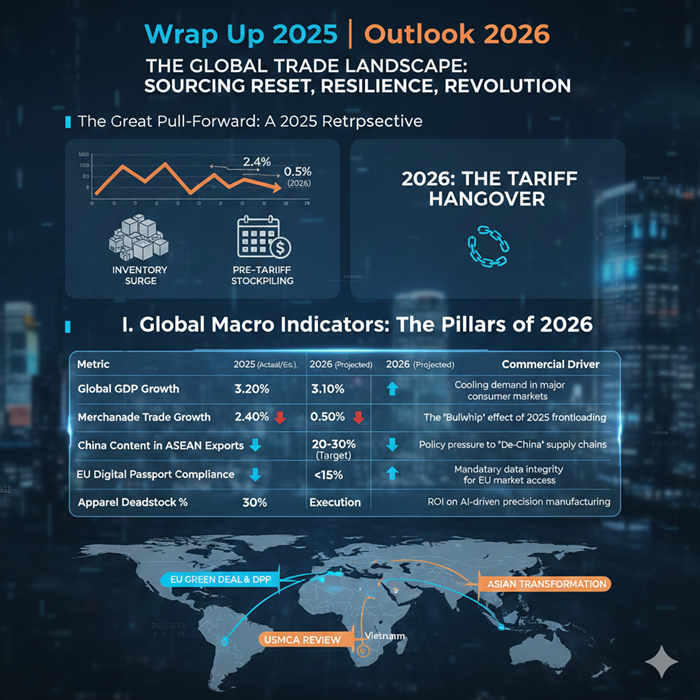

The Global Trade Landscape- Sourcing Reset, Resilience, Revolution: Macro driver…

The Great Pull-Forward: A 2025 retrospective The global textile and apparel industry spent much of 2025 in a state of hyper-vigilance.... Read more

Amazon built a $79 bn apparel empire, now it must learn to be a brand

For over a decade, Amazon has reigned over American fashion with a formula built on convenience, scale, and aggressive pricing.... Read more

India’s T&A sector navigates a "Mixed Bag" first half in FY26

The Indian textile and apparel industry is currently weathering a period of complex recalibration. According to the latest Wazir Textile... Read more

Techtextil 2025: Mapping India’s transition to a global hub for value-added tech…

The conclusion of the 10th edition of Techtextil India in Mumbai marks a definitive transition for the country’s textile landscape,... Read more

China Wave returns to Pitti Uomo 109: Bridging the gap from global factory to de…

The landscape of international menswear is witnessing a structural shift as the ‘China Wave’ initiative returns to the 109th edition... Read more

The Second Life of 3D: Why this tech is more alive than ever in fashion

The fashion industry is no stranger to cycles of hype and disillusionment, and 3D technology has been no exception. At... Read more