North India’s cotton yarn hubs are witnessing a decisive pricing shift as spinning mills struggle to absorb a 3 per cent M-o-M rise in raw cotton costs. In Ludhiana, mills have implemented price hikes of approximately Rs 2–Rs 5 per kg to maintain viability, though downstream demand from garment manufacturers remains cautious. While the benchmark 30-count combed yarn has seen firmer asking rates, the Delhi market remains largely static, reflecting a disconnect between surging input costs and sluggish retail offtake.

Production realities and margin compression

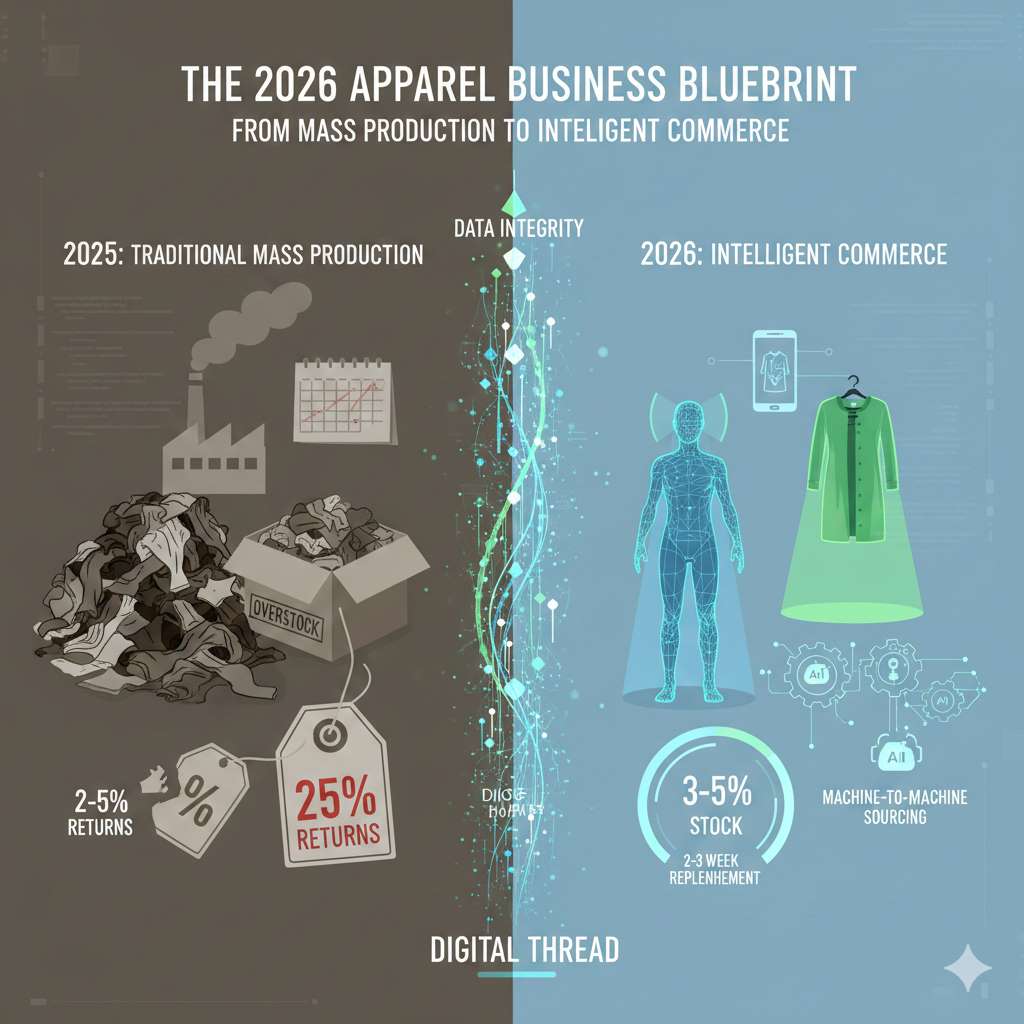

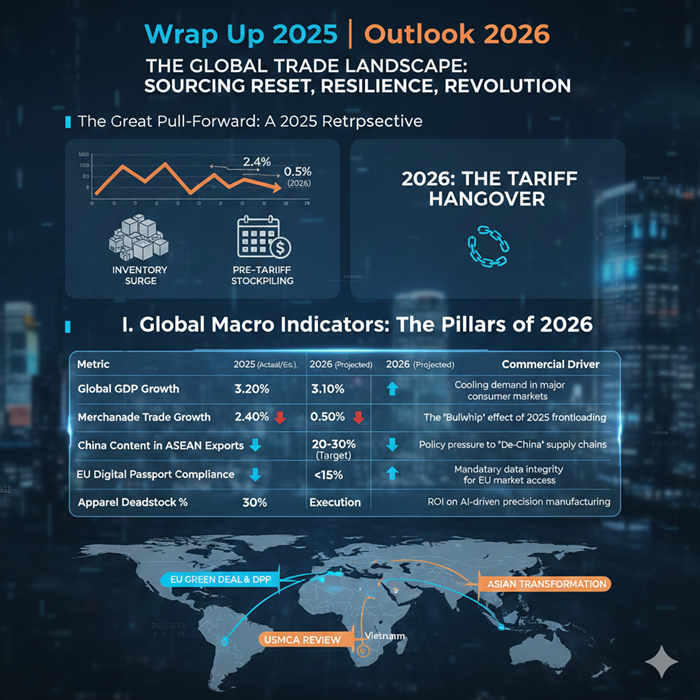

The domestic spinning sector is grappling with a projected 1.7 per cent decline in cotton output for the 2026 season, which is expected to reach a decadal low of 29.2 million bales. Spinning margins are currently under significant pressure as the cost-to-yarn spread narrows to approximately Rs 96–Rs 100 per kg, notes a senior analyst at ICRA. Despite these headwinds, larger mills are prioritizing export markets to China and Bangladesh to offset weak local demand, which has been dampened by recent 50 per cent US tariff impositions on Indian apparel exports.

Panipat’s recycled ecosystem and oversupply hurdles

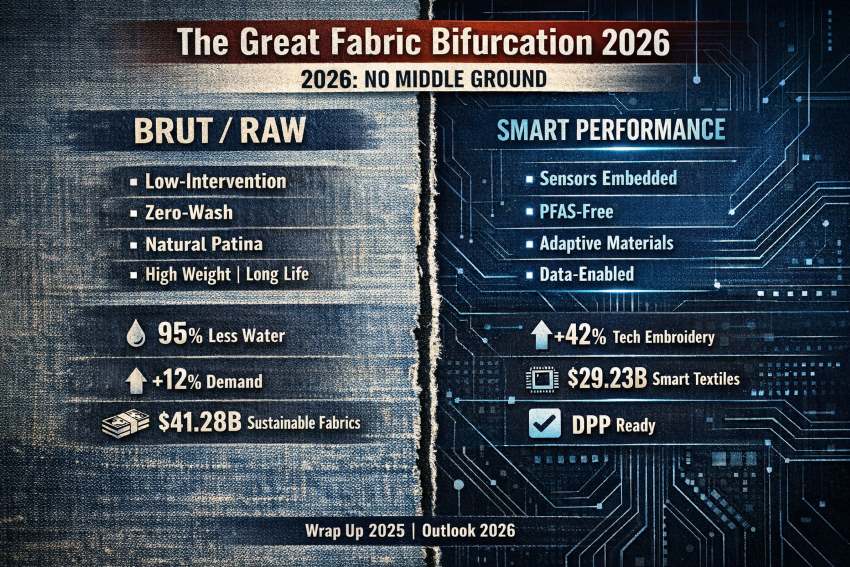

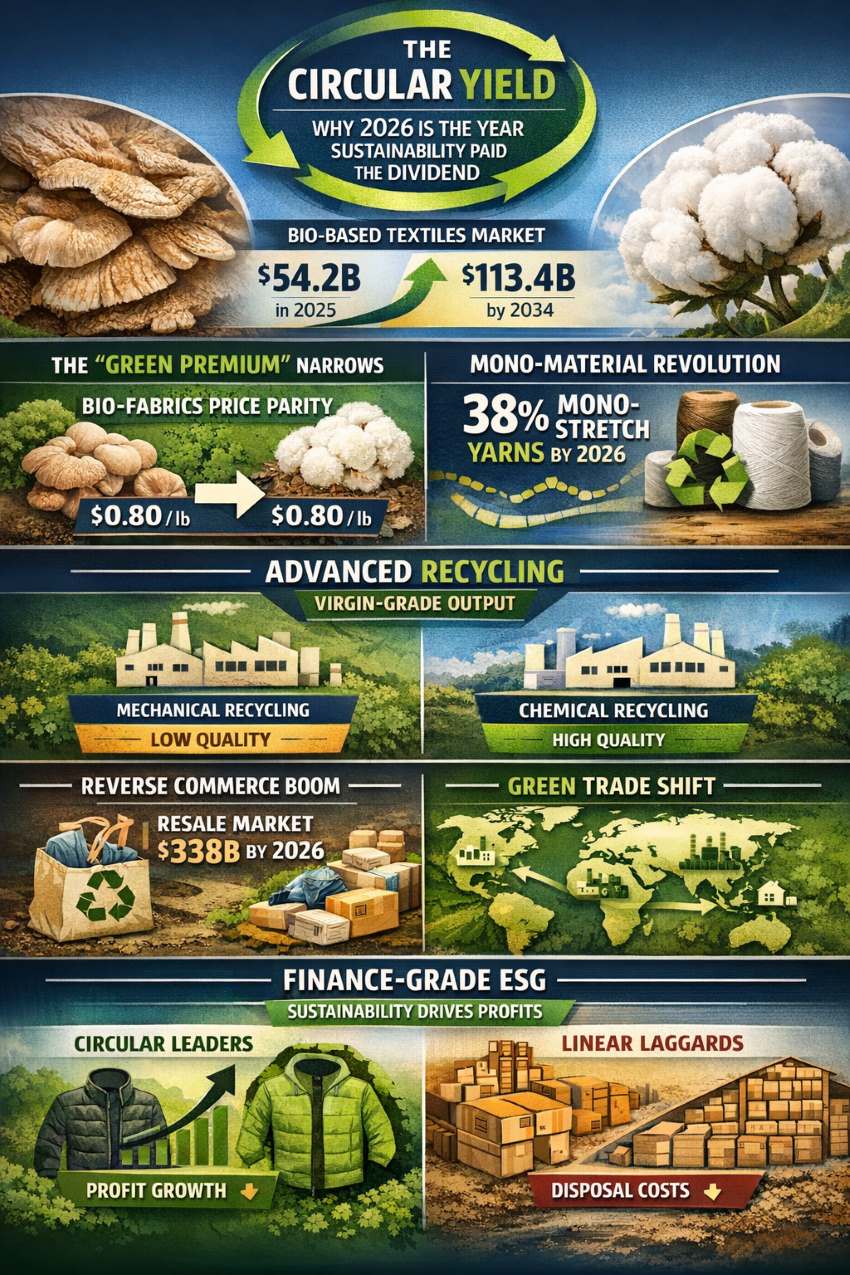

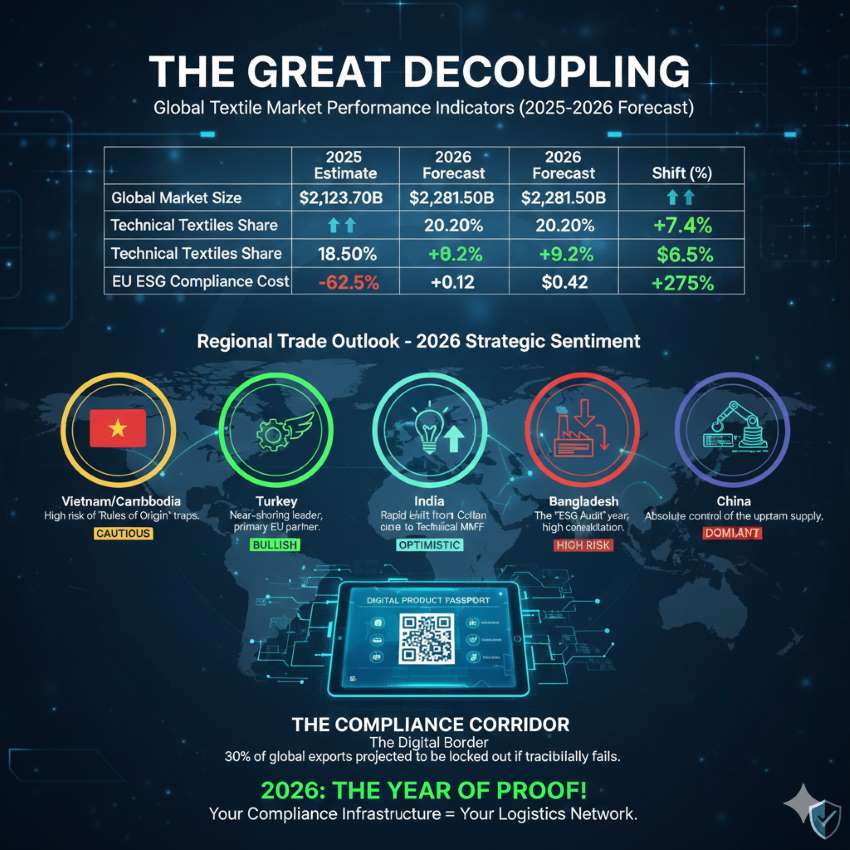

Global hub for circular textiles, Panipat presents a polarized landscape. While recycled cotton yarn prices have firmed due to the scarcity of textile waste imports from Bangladesh, the recycled Polyester-Cotton (PC) segment is battling chronic oversupply. Analysts observe, that high-tech recycled fibers are gaining traction in the home textiles sector, yet the abundance of coarse-count PC yarn has prevented price parity with virgin cotton. The sector’s future increasingly hinges on ‘digital passports’ for fiber tracking, ensuring that Panipat’s Rs 60,000 crore turnover can withstand evolving global sustainability mandates.

Ludhiana and Panipat serve as India's primary centers for knitwear and recycled home textiles, respectively. These markets specialize in high-volume cotton spinning and sustainable PC blends for global retail chains. With a 2026 growth strategy focused on automated spinning and circular fashion, the region is adapting to a 1.7 per cent domestic cotton shortfall through increased U.S. imports.