FW

Online eyewear retailer Lenskart Solutions has invested $1 million for a minority stake in US-based start-up Ditto, which develops graphical 3D models for Lenskart’s virtual trial feature. The online retailer already employs Ditto’s 3D try-on feature on its website and app. Ditto is an e-commerce portal that claims to use patented technology to help users find the right set of eyewear.

Lenskart stated that it will increase Ditto’s usage to improve user engagement on its platform. For instance, Lenskart users will now be able to share images of themselves trying different glasses and frames on social media. The online trial feature also provides preferences and historical data to make frame selection faster for online buyers.

Ditto provides the patented 3D virtual try-on technology that allows customers to see themselves in eyewear in 180° angles. There has been commendable response as there are over 10,000 trials every day. With this association, Ditto has now become a strategic partner for Lenskart, says Lenskart chief executive Peyush Bansal.

The development comes at a time when Lenskart is expanding its supply chain and retail store network. It also announced plans to invest Rs 100 crore in the next two years to fund its store expansion. Lenskart has raised more than $120 million from venture capital firms and other funds till date. The founded in 2010 is a fully online store and started selling offline in 2014. It currently sells in over 350 offline stores in 95 cities in India.

Max has opened a flagship in Kolkata, spread across 11,745 sq ft and four floors. Considering the positioning and location, special attention has been given to material starting from the store facade to the interiors. The store façade boasts of an international look while there are four screen video walls as well showcasing the latest fashion in digital language, reaching out to the shoppers on the high street like a billboard. All four floors consistently deliver the latest seasonal looks. Iconic photos from the daily life of Kolkata have been framed on the wall of the staircase of this 80 year old building.

Samsung panels have been used as video walls while Bangalore-based Nusyn Digital Solutions has worked on the digital content management. The store also features mannequins that have been delivered by Bangalore-based Indo-Nippon while the roto moulded polyethelene torsos have been acquired from New Zealand. Max has now reached a mark of 190 stores across the country and plans to add 45 more stores by end of this fiscal. Max is a value fashion chain from the Landmark Group and was launched in 2004 in India.

After the success of ayurvedic and herbal household products in the Indian market, Baba Ramdev’s Patanjali be launching its line of apparel, with an initial sales target of Rs 5,000 crores. This will include everything from knitwear, denim, underwear to ethnic and sportswear. Ramdev, hopes to break the stranglehold of foreign manufacturers through this business.

Patanjali Ayurved has achieved a tremendous presence around the globe and throughout India since its inception in 2006. Patanjali, with a turnover of Rs 10,561 crores in fiscal year ’17, has been in close competition with major global brands. It is the second-largest pure-play FMCG giant after market leader Hindustan Unilever.

Acharya Balkrishna, the CEO, is the eighth richest Indian. A confidant of Baba Ramdev, Balkrishna holds a 94 per cent stake in Patanjali Ayurved. Patanjali wants to raise long-term project finance to fund its upcoming food parks. The company, which currently has 50 manufacturing units, wants to scale up production at its existing facilities in Maharashtra, Assam, Andhra Pradesh, Madhya Pradesh, Uttar Pradesh and Uttarakhand. Relatively lower selling and administrative overheads have enabled the company to maintain its healthy profitability margins in a highly competitive market.

US fashion house Ralph Lauren has launched a drive to clean up the Indian market of fake and counterfeit products mostly under its Polo brand, before opening its store in the country possibly next year. Ralph Lauren’s lawyers last week conducted raids on a Hyderabad-based company that operated half a dozen ‘Lauren Polo’ branded outlets and seized 6,000 shirts, Tshirts, jeans and other products with the Polo logo.

S K Bansal, a lawyer representing Ralph Lauren stated this was a big seizure and more than 6,000 pieces of garments were seized and their hoardings were removed. He further stated the company has filed around 60 cases in various courts over the years against companies and individuals that manufactured or sold counterfeit Polo Ralph Lauren products.

Jagdeep Kumar Sharma, a lawyer stated that they confiscated about 900 trousers, about 500 shirts and others after the raids on Lauren Polo outlets. The company is planning to change name of its five outlets after coming since it has come under “objection”.

According to the sources, Ralph Lauren, which sells fashion clothing and accessories for men, women and kids, is in talks with Aditya Birla Fashion and Retail for opening to open franchisee Ralph Lauren-branded brick-and-mortar outlets. The company launched by US fashion designer Ralph Lauren is also in negotiations with Myntra for online selling rights.

India has slashed duty drawback rates from October 1. Drawback is the refund of certain duties, internal revenue taxes and certain fees collected upon the import of goods when goods are then used for export. The slash would likely lead exporters to raise prices to balance the loss of revenue from the refund. The rates were lowered in 2016 as a boost to the apparel and textile industry, but the incentive program ended.

The new all industry rates for cotton garments was dropped to two per cent from 7.7 per cent while the duty drawback rate on garments containing cotton and manmade fiber blends will be 2.5 per cent compared to the existing 9.5 per cent and the rate on garments made of manmade fibers will also be 2.50 per cent compared to 9.8 per cent currently.

Clothing items made of silk will be subject to a rate of 4.8 per cent compared to the earlier 7.6 per cent while the rate on wool apparel will also come down to 3.5 per cent from 8.7 per cent. But apparel exporters are not too pleased. They say, in the absence of encouraging drawback rates, exports will further witness a sharp decline just ahead of the peak festival season when the industry was expecting recovery. They say the apparel industry needs to book orders in advance for the next season and the present new rates are unacceptable.

In its latest Asian Development Bank (ADB) report has maintained its April projection for Cambodia's economic growth at 7.1 per cent in 2017 and 2018. The Southeast Asian country's growth is mainly driven by garment export, tourism, agriculture and construction.

Cambodia's economy continues to expand at a robust pace, propelled by export diversification, strong construction and tourism activities, better weather conditions, and supportive fiscal policy, Samiuela Tukuafu, ADB Country Director for Cambodia.

According to the lender's updated report, merchandise exports as indicated by customs data rose by 7.7 per cent and imports by 8.1 per cent in the first half of 2017. The report also stated that inflation averaged 3.3 per cent in the first seven months of 2017. Adding that per month, inflation was highest at 4.2 per cent in March and lowest at 2.3 per cent by July due to softer fuel and food prices.

The average inflation is forecast to come in at 3 per cent in 2017, and edge up marginally to 3.2 per cent in 2018.

"The popularity of Bangladesh RMG is such that every third European has a T-shirt made in Bangladesh and every fifth American wears jeans manufactured in Bangladesh. The country exports $28.14 billion worth of the item or 6.4 per cent of the global share and the export target by 2021 is to push it up to $50 billion. This looks achievable knowing China has shifted its focus from textile to services economy. Amid all these, a question to ponder over is at what cost does this economic development happening? A study by International Finance Corporation (IFC) reveals, every year, 1,500 billion litres of water is used to dye and wash the cotton and clothes for the garment industry. "

The popularity of Bangladesh RMG is such that every third European has a T-shirt made in Bangladesh and every fifth American wears jeans manufactured in Bangladesh. The country exports $28.14 billion worth of the item or 6.4 per cent of the global share and the export target by 2021 is to push it up to $50 billion. This looks achievable knowing China has shifted its focus from textile to services economy. Amid all these, a question to ponder over is at what cost does this economic development happening? A study by International Finance Corporation (IFC) reveals, every year, 1,500 billion litres of water is used to dye and wash the cotton and clothes for the garment industry. This is enough to fill up 600,000 Olympic swimming pools. This water can meet the demand of 8 lakh people for a whole year. For the average jeans, one wears that weighs 1kg, it takes 250 litres of water to wash. This is not at all hard water we are talking about. It’s all drinking water, pumped out from underground.

When such a huge quantity of water is pumped out, a hollow underground is created. As the hollow grows, it creates chances for the earth to cave in. As more and more water is pumped out, the water table goes down. The classic example is Dhaka where every year the water level is dropping by 2.5 per cent. Considering that water table is not infinite, a real disaster will take place sooner.

Increasing pollution levels

The worst part is the garment industries discharge water into rivers and canals after use. This makes the water highly polluted with toxic chemicals and dyes. Bangladesh has around 789 dyeing and finishing factories to serve some 4,000 garment factories, according to the IFC, consuming major part of underground water. If these industries can attempt at reducing water consumption by a fourth with the help of technology, it could drastically reduce the use of chemicals. Additionally, more water needs more gas to heat for the dyeing and finishing of fabrics. Gas, again is a scarce commodity, which is adding to the crisis.

Possible solutions

While Bangladesh uses 250 litres of water, the global standard is 60 to 70 litres for a single pair of jeans weighing 1kg, implying that the country is using four times more water. Experts say, water usage still be brought down to 13.5 litres. For example, every year, around 21.6 million cubic metres of water were saved by the intervention of Partnership for Cleaner Textile (PaCT) programme of the IFC, which worked with 200 factories. According to Nishat Shahid Chowdhury, programme manager, PaCT, these 200 factories could save $16 million a year just by reducing water consumption.

Bangladesh is now conscious about this fact and some companies have started taking positive measures. Earlier Fakir Apparels used 24.96 crore litres of water to wash and dye 1,200 tonnes of fabric a month. But after changing technology, it has reduced water usage to 6.96 crore litres, thereby saving 70 per cent water. The company even recovered its investment of $2.65 lakh in six months. Likewise, Mondol Fabrics has been able to save 27 per cent of water by using new technologies. It needed 120 litres water to process one kg of fabric. Now it needs 80 litres only. It is working to cut down water use further by putting in more technologies.

"For Bangladesh RMG exports, shirting has been a key growth driver over the years. This was complemented aptly by knits and bottoms (non-denim and denim) that helped the country strengthen its position as the preferred global textile sourcing destination. Looking at the increased efficiency and expertise, major MNCs such as H&M, US retail giant Walmart, British retailer Primark, Germany’s posh brands Hugo Boss and Olymp (formal shirts), and many more, have made Bangladesh their preferred sourcing destination."

For Bangladesh RMG exports, shirting has been a key growth driver over the years. This was complemented aptly by knits and bottoms (non-denim and denim) that helped the country strengthen its position as the preferred global textile sourcing destination. Looking at the increased efficiency and expertise, major MNCs such as H&M, US retail giant Walmart, British retailer Primark, Germany’s posh brands Hugo Boss and Olymp (formal shirts), and many more, have made Bangladesh their preferred sourcing destination.

Statista’s data reveals, the global shirt market stood at $51 billion with total consumption of 2.5 billion pieces in 2016. This is further expected to reach $58.5 billion (in value terms) and 2.83 billion pieces (in volume terms) by 2020. Bangladesh has a key role to play in this growth. The country contributed around 10 per cent to the total global shirt import in 2016. But despite this growth, shirt as a category has somehow failed to keep pace with growth of other products. As Khondoker Mahibur Rahman, MD, Stanley Fashion explains that of late they are getting more demand for sweaters, jackets, denim and other products which found base in Bangladesh after shirts.

Shirts losing ground Even the recent BGMEA data reflects the industry sentiments. In 1996-97, the export earnings from shirts was $759.57 million, while for trousers, jackets, t-shirts and sweaters, the value of exports were $230.98 million, $230.98 million, $391.21 million and $196.6 million, respectively. In 2015-16, in terms of value (export), shirt stood at $2,317.09 million while trousers, jackets, t-shirts and sweaters registered drastic growth to touch $6,319.00 million, $3,774.08 million, $6,118.53 million and $3,182.47 million, respectively.

The growth of denims is one of the key reasons of falling demand for shirts, say experts. Rahman also says about 75 per cent of demand is for denim today. The way the industry has been investing in denim is unprecedented, no other product has grown like this and today the country has integrated strengths that did not exist about a decade ago, and this has been pushed by buyers who now look at Bangladesh as a major supplier, both in basic and fashion segment. As Md Khosru Chowdhury, Chairman & MD, NIPA Group, points out in shirts, which was once the company’s biggest category, casual denim shirts are witnessing greater traction. Moreover, there is no real focus on the category as there are many players in the segment and the price offered is competitive.

A ray of hope

Statista predicts, if global demand for shirts stands at $53.36 billion (in terms of value) and 2,580 million pieces (in terms of volume) in 2017, the same would register a steady increase in coming years to touch $55.17 billion (in value terms) and 2,657 million pieces (in volume terms) by 2018, to further increase to $56.8 billion and 2,740 million pieces respectively by 2019. While challenges exist, there are still some players who are going strong. According to Maashed R Abdullah, Ddirector, Dressmen, the business is more difficult these days as customers are not realising how much effort is put into manufacturing quality products. Prices have dropped significantly but customer’s demands are increasing one needs to find a middle ground where customer and the manufacturer stand to gain.

Many feel shirt business is not at its best today. Compared with other RMG products, shirt is not in the frontline of Bangladesh exports any more. The fact is the country has failed to explore markets for shirts. To grow in shirts, they would have to find new customers and markets. Additionally the price from buyer must be increased; otherwise it would be difficult to survive. There is 50:50 demand for both casual and formal shirts. Men’s formal and casual shirts, ladies blouses, school shirts are items that are seeing greater demand.

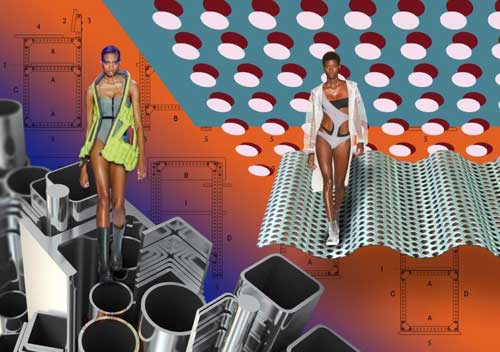

MarediModa presents Trends Summer 2019 for Swimwear/Intimate Apparel/Athleisure Fabrics and Accessories, theme for teh season is Exploring the new without leaving the past. The trends forcasting is done by Trend forecasting by David Shah and Stijlinstituut Amsterdam.

Ad hoc (Swimwear)

An ad hoc, dynamic design process gives the freedom to pick, mix, colour and layer. Modular outfits combine and connect in new ways to morph from swimwear to sportswear to anywear. Fabrics: fabrics are selected to provoke creativity and industrial ambition in design. Choose compact, functional swim and sports fabrics, either plains or with surface or knit-in designs - grids, meshes and heather effects - to represent construction materials. Patterns: think retro construction toys, then mash that with computer graphic patterns, laser cut holes, printed meshes and rhythmic graphic patterns and jacquard weaves. Colours: Meccano shades without the flatness of pure primaries - these are more sophisticated mid-tone brights to colour block with sturdy darks and hazy pastels. Silhouettes: a hard-core sporting foundation for a fun-filled lifestyle. Styles are bold, sporty and graphic.

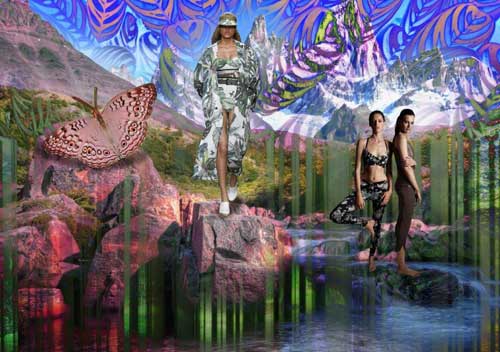

Next Nature (Swimwear)

Take a holistic approach, considerate of the full process from ethical sourcing, integrity of design, production methods and disposal after use. Fabrics: manmade, inspired by nature, these smart fabrics mimic nature’s sophisticated aesthetics and intelligence. Surfaces are smooth skin, fur or carapace. Patterns: the forest inspires with tonal palm leaves and feathers. Natural irregularities are mimicked using digital language to create magic marls and natural stone effects. Colour: deep natural shades combine urban and natural environments. Forest shades feature with dense pines and cedars, utilitarian khakis, browns and burnished terra tints. Silhouettes: covered silhouettes provide space for hyper-scale patterns. To contrast we propose styles that help nature by shaping the body using body-tuning cuts and tailoring.

Artful (Swimwear)

Traditional folk craft skills can be re-interpreted or blended with high-tech computer graphics for a synthesis between nostalgia and optimism for a global future that is refreshing and exciting. Fabrics: cotton-touch fabrics contrast with skin-touch materials. Basic charmeuses sit alongside crochets, plissé, piqués and honeycomb effects. Patterns: wildly innovative, colourful, fun and bold. Small retro-inspired graphics mix with free-spirited Memphis inspired patterns. African patterns mix with cut and pasted stripes. Colours: fresh, bright hues for bold plains or clashing contrasts. Bright colours are used to collage and create happy harmonies. Silhouettes: Pretty bras and briefs are intimatewear for swimwear.

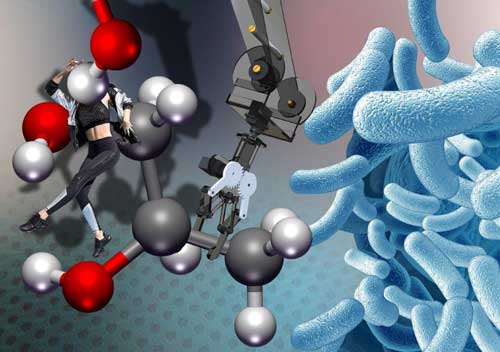

Into the cloud (Swimwear)

Today’s fabrics reach for the clouds with futuristic prints and fibre performance stories. Fabrics: experimentation in intelligent, multi-disciplinary design and manufacturing leads to hyper-dynamic plissés, responsive and sensory materials, fabrics that protect you from paparazzi and warn you of air-born hazards. Patterns: the consumer can co-create: Multi-colour gradients, psychedelic and slightly intergalactic, have the attraction of flowing liquids. Colours: acid and glowing shades where gradient colouring and rasterized patterns add to the virtual and meditative appearance. Silhouettes: experimental novel garment manufacturing methods include 3D printed details and accessories. Fit is optimised using body-scanning technology.

Active Reactive (Intimate Apparel)

Garments containing personalized health solutions and beauty boosting properties. Fabrics:go lighter, go longer: an exploration of ultra-light support and maximum comfort in breathable fabrics that fit like a second skin or provide compression to improve performance. Patterns: graphic patterns, graduated or engineered effects aid function as well as look. Colours: a palette of contemplation, pure and neutral for energetic performance and active intimate looks. Silhouettes: 3D data modelling and prototyping offer extreme comfort or graduated compression in intelligent layers.

Dress up (Intimate Apparel)

Used garments and waste materials from the fashion industry are recycled and even more valuable as a result: the appreciation of the value of life includes the environment we live in. Fabrics: fabrics take the lead, they are the story and they are intricately embellished, beaded, sequined, fringed, encrusted or ravishingly printed. Patterns: flowers and ornaments. The source is traditional, yet re-worked in modern designs and combinations. Colours: warm and rich in royal reds and blues that combine or vibrate against corals, gold, purples and deep burgundy reds. Silhouettes: from corsetry-inspired classics to activewear innovation, shape solutions are complex.

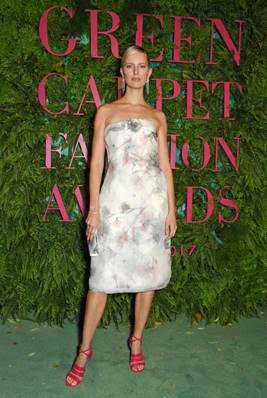

The Green Carpet fashion awards brought star power to fashion’s drive to sustainability.

The unique awards put sustainability at the heart of fashion in a ceremony fit for the Oscars.

Dakota Johnson wore a Gucci black organic silk tulle dress with Swarovski crystals and recycled brass embroidered cups. Swarovski crystal embroideries were also featured on the straps, bodice, belt and skirt.

Zoe Saldana wore a timeless Giorgio Armani Privé look. The 100 per cent silk dress was handmade in Italy.

Roberta Armani wore Giorgio Armani. The dress was 100 per cent silk GOTS certified silk from Clerici.

Vittoria Puccini was wearing a dress created using Italian end-of-line upcycled taffetas silk and certified organic silk lining. The metal components were reclaimed and covered with silk offcuts.

Elsa Hosk was wearing a breath taking Alberta Ferretti gown created from certified organic silk chiffon. The gown features lace detailing from factory deadstock which was hand-dyed. The zips were reused from old samples to ensure nothing goes to waste.

Amber Valletta was wearing a Missoni which incorporates intricate hand embroidery and bustier boning upcycled from an old dress - a perfect way to reuse materials that could otherwise be forgotten or even end up in landfill. The Italian produced silk base is certified GOTS organic, with a zip made from recycled polyester.

Karolina Kurkova was wearing Ferragamo, a dress embroidered with floral applications with lead-free advanced crystals from Swarowski, used to give light and emphasize the flower embroidery. The outfit was made of silk organza woven and printed with GOTS certified fibers.

Gisele Bundchen was in a bespoke emerald green goddess gown by Stella McCartney, crafted from sustainably sourced viscose from sustainably certified forests in Sweden.

Arizona Muse was in a bespoke print gown with handmade lace detailing by Stella McCartney, crafted from recycled archival print fabrics.

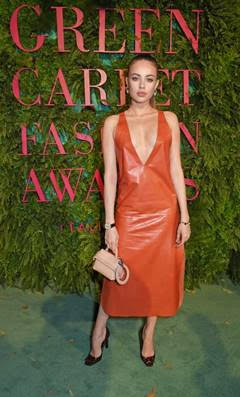

Xenia Tchoumitcheva was wearing Tods. The piece was created from unused archive leather that was originally used to research and test terracotta dye colors. This leather was reworked and upcycled into a simple sheath dress.

Jasmine Trinca was wearing Prada. This look was made using the highest quality Italian produced silk, featuring certified organic silk organdie, lead-free Swarovski crystals and flower embroideries created out of silk offcuts from the cutting process.

Eva Riccobono was wearing a stunning Trussardi gown made from organic Italian silk, featuring Piñatex, a natural leather alternative made from unwanted pineapple leaves. Piñatex provides a new, additional income for farmers while creating a vibrant new industry for pineapple growing countries.

Matilde Rastelli was wearing an archive Emilio Pucci dress. Bringing out pieces from the archives for events is a wonderful way to be more sustainable through not using new materials, but it also allows stunning pieces to continue to be worn, appreciated, and admired.

Matilda de Angelis was wearing a stunning Miumiu gown crafted from GOTS certified organic silk crepe satin, produced and finished in Italy. The dress is embellished with certified Swarovski advanced elements lead-free crystals, ensuring a responsibly made look with minimal impact.

Cara Taylor was wearing a Max Mara, made of camel hair fabric, sourced from Inner Mongolia. The thread, label, and zip for this look were all made from recycled polyester.

Kiki Willems was wearing Marni, in a stunning look which is made from certified organic silk in many guises - delicate silk crêpe, silk faille, and luxurious crêpe satin. These Italian fabrics have all been certified by Global Organic Textile Exchange, which is the world’s leading processing standard for textiles made from organic fibers.

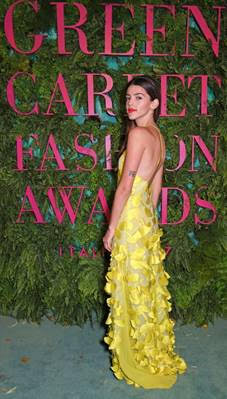

Calu Rivero was wearing a dress made from an Italian silk and Newlife jacquard with exclusive Laura Strambi’s design. Newlife is a completely Italian recycled polyester, created from used PET plastic bottles. These are sourced, mechanically processed and spun into yarns in Italy, with a fully traceable supply chain. This saves energy and reduces CO2 emissions compared to creating brand new polyester fiber.

Kasia Smutniak was wearing Fendi. The materials from this look were selected from Fendi archives so that no new materials have been produced.

Nicoletta Romanoff was wearing an Ermanno Scervino dress crafted from the highest quality GOTS certified organic silk, with carved embroidery. The carved embroidery is a handmade technique also known as Guipure. This kind of embroidery became very popular in Italy between the XVI and XVII centuries, and was originally used for trousseaus and linen.

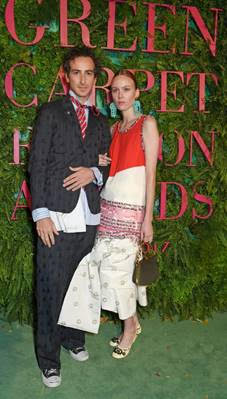

Camilla and Carolina Cucinelli were both wearing Brunello Cucinelli. Brunello’s vision entails that the memory of an important humanistic factor such as craftsmanship is preserved and passed on to future generations.

Doina Coibanu was wearing Antonio Berardi. This look has been made by recycling a vintage Bernardi toile, and is made from antique Italian tulle, and vintage Swarovski crystals.

Geppi Cucciari in an Antonio Marras look featured a vintage military parka which has been cut, modified and embellished with special jacquards and precious embroideries. The stunning dress was made from GOTS certified organic silk chiffon and crepe de chine.

Malgosia Bela was wearing a beautiful Agnona dress. The cashmere is sourced from Mongolia and entirely processed (washed, combed, woven, teased) in a wool mill in Italy.

Alessandro Roja was wearing a Zegna navy blue tuxedo made from Zegna’s Achill Farm wool. Ermenegildo Zegna has had a longstanding relationship with farmers in Australia and New Zealand, and now has its own farm, Achill. The land is kept in line with Ermenegildo Zegna’s recognition of its duty as a custodian of the landscape and its commitment to respect the environment.

Maria Grazia Cucinotta was wearing a Laura Biagiotti. This gown was colored with natural vegetable dyes, featuring handmade ruffles created by experienced seamstresses in the Laura Biagiotti atelier.