FW

The India Sourcing Conclave (ISC) 2025, organized by the Buying Agents Association (BAA), will be held from February 12-15 at India Exposition Mart Ltd (IEML), Noida, alongside Bharat Tex. The event features an exhibition and knowledge seminars, with a strong focus on ESG in global trade.

BAA, which facilitates over $4 billion in annual export orders across handicrafts, textiles, home decor, and apparel, aims to enhance India’s merchandise exports through ISC. The conclave will attract global buyers, sourcing consultants, embassy representatives, exporters, and logistics professionals, along with BFSI firms, compliance bodies, and testing agencies.

Supported by the Export Promotion Council for Handicrafts (EPCH) and IEML, ISC 2025 is backed by industry partners like SAR Transport Systems, Cotecna Inspections, and Marudhar Chemicals.

The Union Minister for Textiles, Giriraj Singh, will inaugurate Bharat Tex 2025 on February 12 at Expo Mart, Greater Noida. The event, building on the success of its inaugural edition in 2024, will bring together global buyers, policymakers, and industry leaders to drive business opportunities and partnerships.

Sudhir Sekhri, Chairman of AEPC, emphasized the event’s strong sustainability focus. "Bharat Tex 2025 is committed to promoting eco-friendly practices with innovations in organic fabrics, recycled materials, and energy-efficient technologies," he said. He also highlighted the rising global trust in India’s textile sector, with the readymade garment (RMG) industry experiencing significant growth.

"India's RMG exports saw an 11.6 per cent increase from April-December 2024-25 over the same period last year. Free trade agreements (FTAs) and supportive state policies have further boosted the sector. The Union Budget 2025-26 has also reinforced growth by providing MSME credit support and rationalizing customs duties,” Sekhri added.

The event will feature participation from 110 countries, along with global brands and retail giants. High-level government-to-government (G2G) and business-to-business (B2B) meetings, strategic MoUs, and joint ventures are expected to drive foreign investment.

Bharat Tex 2025 aims to position India as a key player in the global textile market. It will showcase advancements in sustainability, circularity, and digitization. Attendees can explore fabric testing zones, product demonstrations, thematic discussions, and master classes by industry experts.

With top policymakers, global CEOs, and industry stakeholders in attendance, Bharat Tex 2025 is set to be a landmark event, strengthening India’s role as a reliable textile hub.

The 2nd edition of Bharat Tex 2025-Handicrafts will take place from February 12-15, 2025, at the India Expo Centre & Mart, Greater Noida. This major event, part of the global Bharat Tex 2025 trade fair, will highlight India’s handicraft traditions alongside modern innovations.

Organized by the Bharat Tex Trade Federation (BTTF) and supported by the Ministry of Textiles, the event will run concurrently at two venues Greater Noida (Feb 12-15) for handicrafts, garment machinery, and chemicals, and Bharat Mandapam, New Delhi (Feb 14-17), covering the entire textile value chain.

With backing from 12 Textile Export Promotion Councils, including EPCH, the event is set to attract over 5,000 exhibitors, 6,000+ buyers from 110+ countries, and 1,20,000+ visitors. It aims to drive global partnerships, showcase sustainable practices, and highlight cutting-edge textile technologies.

EPCH Chairman Shri Dileep Baid stated, "This event blends our rich textile heritage with innovation, reaffirming India's leadership in sustainable and modern textiles."

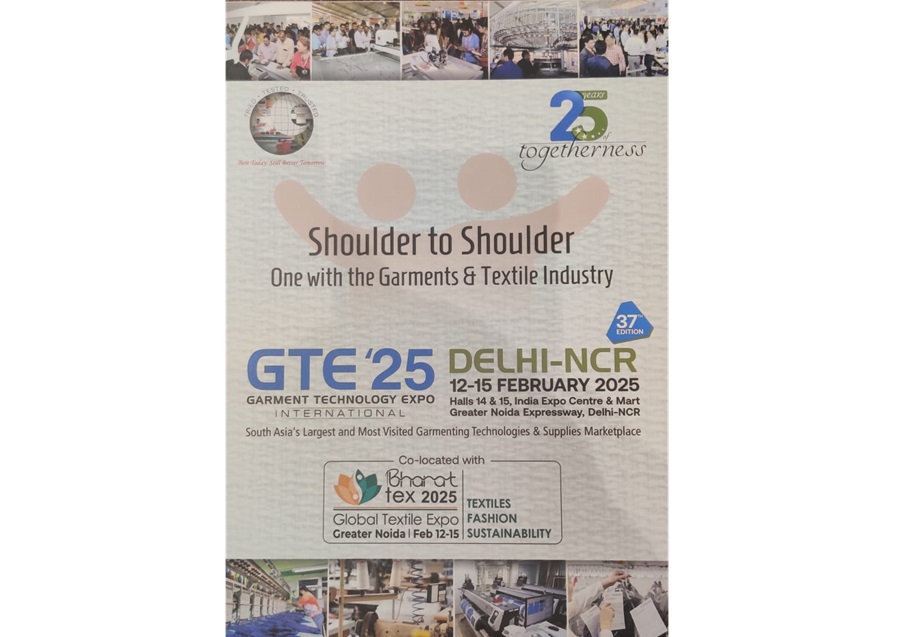

The 37th Garment Technology Expo (GTE) 2025 will take place at the India Expo Centre and Mart, Greater Noida, alongside Bharat Tex 2025. This premier event, set for February 14-17, will feature cutting-edge garment manufacturing technology, innovations, materials, and services.

GTE 2025 will host 170 exhibitors representing over 600 brands across 120,000 square feet in two halls. The expo will highlight advancements in machinery, consumables, infrastructure, processes, trimmings, logistics, and communication solutions.

Bharat Tex 2025, organized by textile export councils and supported by India’s Ministry of Textiles, will run concurrently at Bharat Mandapam, New Delhi, and Greater Noida. The event aims to position India as a global textile leader, covering the entire supply chain from raw materials to finished products.

A recent price comparison study by the Confederation of Indian Textile Industry (CITI) highlights significant cost competitiveness challenge for Indian yarn manufacturers against their Chinese counterparts in January 2025. The data, focusing on the price trends of Polyester Staple Fiber (PSF) and Viscose Staple Fiber (VSF), indicates a considerable price difference impacting the Indian industry. This challenge gets escalated further due to broader trends in the global textile market, opines Sanjay K Jain, Chairman ICC National Textiles Committee & MD, TT Limited.

The CITI report compares domestic prices for MSME (Micro, Small, and Medium Enterprises) spinners in India with international prices as given by the China Chemical Fibre Website (CCF), a key source of chemical fiber market information in China. The analysis reveals Indian MSME spinners paid a substantial premium for both PSF and VSF throughout January.

Growing PSF price disparity

The data shows a fluctuating but consistently high price difference for PSF between the Indian domestic market and international prices. The following table summarizes the weekly PSF price comparison:

Table: PSF prices difference

|

Week of January |

Exchange Rate ($/Rs) |

CCF Price ($) |

CCF Price (Rs) |

Domestic Price (Rs) |

Price Difference (Rs) |

Price Difference (%) |

|

1st |

85.75 |

0.85 |

72.75 |

99 |

26.25 |

36.08% |

|

2nd |

86.25 |

0.85 |

73.46 |

99 |

25.54 |

34.77% |

|

3rd |

86.4 |

0.87 |

75.13 |

100.13 |

24.99 |

33.27% |

|

4th |

86.44 |

0.87 |

75.13 |

100.5 |

25.37 |

33.78% |

As the table reveals, the price difference ranged from Rs 24.99 to Rs 26.25 per kg. As a percentage of the international price, the difference remained consistently above 33 per cent, highlighting a significant cost disadvantage for Indian spinners.

VSF prices also higher in India

Similarly, VSF prices in the Indian domestic market were also significantly higher than international prices. The following table illustrates the weekly VSF price comparison.

Table: VSF price difference

|

Week of January |

Exchange Rate ($/Rs) |

CCF Price ($) |

CCF Price (Rs) |

Domestic Price (Rs) |

Price Difference (Rs) |

Price Difference (%) |

|

1st |

85.75 |

1.61 |

137.8 |

160 |

22.2 |

16.11% |

|

2nd |

86.25 |

1.61 |

138.74 |

160 |

21.26 |

15.32% |

|

3rd |

86.4 |

1.61 |

139.14 |

160 |

20.86 |

14.99% |

|

4th |

86.44 |

1.62 |

139.73 |

160 |

20.27 |

14.50% |

The data reveals a price difference ranging from Rs 20.27 to Rs 22.20 per kg. In percentage terms, the difference fluctuated between approximately 14.50 per cent and 16.11 per cent of the international price. While the percentage difference is lower for VSF compared to PSF, it still represents a notable cost disadvantage for Indian manufacturers.

Reasons for price gap and impact

The CITI report suggests international prices considered are not Indian landed prices. If these raw materials were to be imported into India, additional costs such as CIF (Cost, Insurance, and Freight), Basic Customs Duty (BCD), and other related charges would be added to the international prices, potentially narrowing the gap. However, the existing disparity still poses a challenge for Indian manufacturers. The report also highlights that domestic prices are specifically for MSME spinners and include discounts, indicating that larger players might face even higher input costs.

This price differential significantly impacts Indian yarn makers competitiveness, squeezing their profit margins and hindering their ability to compete with Chinese manufacturers in the global market. The higher raw material costs could force Indian manufacturers to raise prices for their finished products, making them less attractive to international buyers.

Jains analysis offers a crucial context to these price disparities, highlighting the dominance of Man-Made Fibers (MMF) in the global textile market, with a 70 per cent share. This reinforces the importance of PSF and VSF pricing for India's competitiveness. Jain also points out the stagnation of India's cotton sector, with declining yields, making the focus on MMF even more critical.

He emphasizes the significant price disparity in raw material sourcing between India and China, raising concerns about India's ability to compete effectively. He questions the reliance on tariffs and advocates for a more robust competitive structure that allows for the free flow of raw materials. Drawing attention to the success of countries like Bangladesh and Vietnam, Jain underscores the importance of sourcing flexibility, even without abundant domestic raw materials. This suggests that India needs to strategically adapt its policies to facilitate access to competitive raw materials internationally.

The report also notes that CCF was closed from January 25 to February 4, 2025, due to the Chinese New Year holiday, and this period was not included in the analysis. The closure could potentially influence price dynamics in the subsequent weeks, a factor that warrants further observation.

What lies ahead…

CITI’s data, and Jain's expert analysis, underscores the need for a comprehensive analysis of the factors contributing to the price disparity between domestic and international prices of PSF and VSF. It also highlights the importance of policy interventions and industry initiatives to enhance the competitiveness of Indian yarn manufacturers in the global arena. Continuous monitoring of price trends and proactive measures, including potentially rethinking raw material sourcing strategies, are crucial for the sustained growth and development of the Indian textile industry.

Patagonia has successfully streamlined its color management process using Discover e-Solutions (DeSL) Color Lifecycle Management (CLM) software. This technology enhances efficiency, sustainability, and collaboration with suppliers.

DeSL, a leader in digital transformation for fashion and retail, highlights Patagonia’s success with CLM, reinforcing the brand’s commitment to innovation and environmental responsibility. “With DeSL’s CLM, we’ve improved our color evaluation workflow, automated lab dip reviews, and tracked production yardage using spectral data,” said Matt Swartz, Sr Color & Surface Design Manager at Patagonia. “The web portal also centralizes communication and documentation with suppliers.”

The CLM solution enables Patagonia to manage both spectro-readable and non-spectro-readable submits, reducing errors and improving color accuracy. By automating key processes, the brand enhances operational efficiency while aligning with its sustainability goals.

DeSL values its ongoing partnership with Patagonia and remains dedicated to supporting its technological and environmental advancements.

The Global Sourcing Expo, recognized as one of the Top Global Fashion Expos by Forbes, is set to return to Sydney from June 17-19, 2025, before heading to Melbourne in November. This highly anticipated event continues to build on its 15-year legacy, attracting thousands of leading global suppliers in apparel, footwear, textiles, and homewares.

Last year’s Sydney expo saw a 48 per cent year-on-year rise in attendance, with over 4,450 visitors attending the three-day event. Marie Kinsella, CEO of International Expo Group, says this growth reflects the increasing need for a centralized sourcing hub.

“The show was designed to solve a major challenge for Australian trade buyers eliminating the need to travel abroad to connect with global suppliers. Here, they can engage with hundreds of manufacturers, brands, and industry experts, all under one roof,” she said.

The 2025 edition promises an enhanced experience with a dynamic exhibitor lineup, insightful seminars, and key industry partnerships. The Sourcing Seminar Series will return, featuring experts discussing the latest trends, eCommerce strategies, AI in marketing, sustainability, and supplier management.

“With an outstanding speaker lineup and pressing industry topics, this year’s seminar series is set to be our best yet,” Kinsella added.

Once again, the event will feature the China Clothing Textile Accessories Expo, showcasing high-quality products from diverse global brands.

Exhibitor registration is now open, and booths are filling fast. “With just four months to go, we encourage exhibitors to secure their stands and stay updated via our social media channels,” said Kinsella.

The Global Sourcing Expo Sydney is a must-attend event for fashion buyers, retailers, and sourcing professionals looking to connect, collaborate, and stay ahead of industry trends.

British Wool has reported a nearly 25 per cent rise in auction prices, driven by strong demand from buyers. The buoyant market comes as sheep and beef sectors face rising costs.

The organisation, which holds 18 online auctions annually, typically offers between 1,000 and 1,500 tonnes per sale. So far in the 2024/25 season, 57 per cent of the year’s wool has been sold, with some key types exceeding 60 per cent. Most of the 10 auctions held to date have seen full clearances.

British Wool Chairman Jim Robertson highlighted the positive trend, urging farmers to send in their remaining wool. “We appreciate prices are not at the level we’d like, but they are improving. This is encouraging, and we need more farmers to return their wool to maximise returns,” he said.

British Wool continues to push for greater use of British fleece in manufacturing, working with retailers and brands. Recent initiatives include a partnership with Shaun the Sheep to promote wool carpets.

“As a collective, we focus on adding value for our members,” Robertson added. “Our efforts to create demand translate into more competitive auctions and help move British wool beyond being just a commodity.”

The organisation remains committed to supporting UK sheep farmers, ensuring wool collection services and sustainable demand. Robertson urged members to send in any remaining wool, emphasizing ongoing market interest.

“With demand still strong, now is the time to act,” he said. “If you have wool on-farm, contact us to arrange delivery or collection.”

Leading labour rights groups warn that factory owner influence in Bangladesh is undermining the garment industry’s top workplace safety programme, endangering workers. In a memorandum to global apparel brands, the Clean Clothes Campaign (CCC), Worker Rights Consortium (WRC), and Maquila Solidarity Network (MSN) call for urgent reforms to restore the programme’s integrity.

The International Accord for Health and Safety in the Textile and Garment Industry, a binding agreement between brands and unions, has saved thousands of lives. However, in 2020, its Bangladesh operations were transferred to the Ready-Made-Garment Sustainability Council (RSC), where employers gained influence, weakening enforcement and sidelining worker representatives.

New research reveals employer interference has weakened safety enforcement, allowed non-compliant factories to keep exporting, and delayed a crucial boiler safety programme.

The RSC emerged after resistance from factory owners backed by the Sheikh Hasina government. With Bangladesh’s political shift, NGOs urge brands to push for restructuring the RSC to remove employer control, ensuring it can protect garment workers without obstruction.

The memorandum stresses that brands must uphold safety commitments, pay fair prices to suppliers, and support reforms. The Accord remains the strongest model for workplace safety, but its governance must remain free from corporate interference.

The issue will also be a key topic at this week’s OECD Forum on Due Diligence in the Garment and Footwear Sector, highlighting global interest in binding agreements for human rights compliance.

“A governance reset is crucial to safeguard workers’ rights and maintain alignment with due diligence laws,” said Ineke Zeldenrust of CCC. NGOs urge brands to act swiftly to protect workers and sustain Bangladesh’s position in global apparel production.

Karl Mayer Technical Textiles is celebrating the strong market response to its latest innovations, the Max Glass Eco and TM Weft 2. Launched last year, both machines saw above-average demand in 2024, with double-digit sales in key markets like China and India.

The momentum continues in 2025. “In the first week of January alone, we received eight inquiries from China for our TM Weft 2,” said Jan Stahr, Regional Sales Manager. The rise in interest follows successful installations in a Chinese textile hub, where the machine is reducing wastewater impact and boosting efficiency for traditional waterjet weaving mills. The TM Weft 2 also appeals to warp knitting customers seeking new applications.

Offering a 20 per cent performance boost over its predecessor, the TM Weft 2 stands out with its improved crankcase system, ease of use, and durability. Meanwhile, the Max Glass Eco is gaining traction in the wind power industry, producing high-output glass fiber fabrics at speeds of up to 1,800 rpm. With optional modifications available, it meets diverse production needs while offering a shorter amortization period.

With strong market alignment and cost-effective advantages, Karl Mayer’s latest machines are driving increased adoption across key textile sectors.