FW

The textile industry is constantly evolving, and one of the most exciting new developments is 3D weaving. This innovative technology allows for the creation of seamless, three-dimensional garments and fabrics with intricate designs and complex shapes, directly on the loom.

Making a mark with innovations and applications

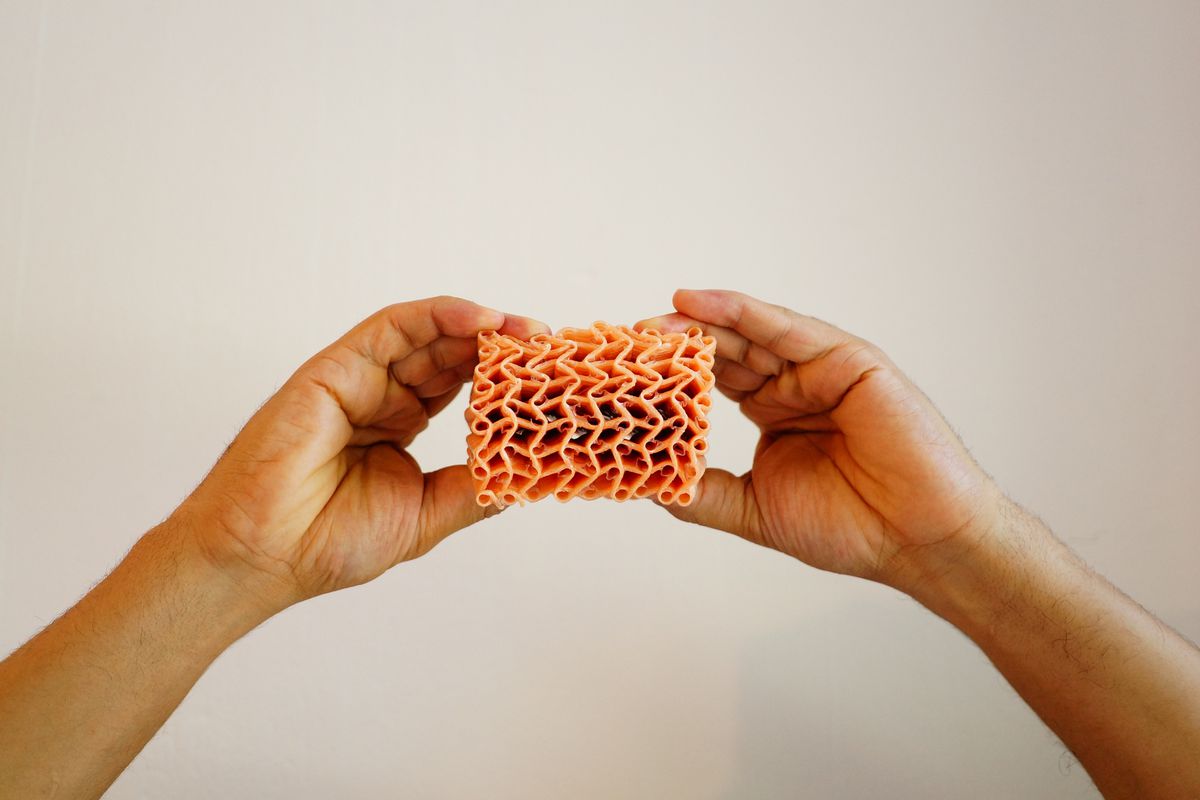

Unlike traditional weaving, which produces flat fabric, 3D weaving interlaces yarns in three perpendicular directions (x, y, and z) to create complex shapes and structures within the fabric itself. This opens up a world of possibilities for both aesthetics and functionality.

While both 3D weaving and seamless/whole garment knitting produce seamless garments, they differ in their underlying technology and end applications. 3D weaving interlaces yarns in three dimensions to create woven fabrics with complex structures and thicknesses. It’s ideal for tailored garments, technical textiles, and applications requiring high strength and durability. Seamless/whole garment knitting on the other hand uses knitting needles to create complete garments with minimal seams. It is well-suited for sportswear, knitwear, and applications prioritizing flexibility and comfort.

The advantages of 3D weaving are many. Most importantly, it minimizes fabric waste by creating near-net-shape products. The seamless garments that are made with this technology offer superior comfort and fit. 3D woven fabrics can provide improved breathability, moisture management, and support. Also it can help create complex shapes and intricate patterns that directly on the loom.

Innovations

Multi-layer fabrics: 3D weaving can produce fabrics with multiple layers, each with different properties or materials. This allows the creation of garments with integrated functions, such as moisture-wicking inner layers and abrasion-resistant outer layers.

Complex shapes: 3D weaving creates seamless, three-dimensional shapes directly on the loom, reducing the need for cutting and sewing. This is particularly useful for producing complex components like shoe uppers, contoured cushions, and even medical implants.

Integrated functionality: This technology can integrate functional elements directly into the fabric, such as sensors, actuators, and electronic components. This has applications in areas like smart textiles, wearable technology, and medical devices.

Applications

3D weaving is seeing numerous applications. In fashion, it leads to seamless garments, complex shapes, and intricate textures for high-end fashion and sportswear. In technical textiles it creates lightweight and strong composites for aerospace, automotive, and construction industries. In medical space, it helps in producing implants, prosthetics, and customized support structures with biocompatible materials. The technology is being used to produce sports equipment like helmets, protective gear, and footwear with enhanced performance and comfort.

Indeed, 3D weaving also has certain limitations. One major one is cost as 3D weaving technology is currently more expensive than traditional weaving. Production speed is another bane as 3D weaving can be slower than traditional methods, especially for complex designs. Limited material selection is also an issue as not all yarns are suitable for 3D weaving. What’s more designing 3D woven fabrics requires specialized skills and software.

While 3D weaving can create near-net-shape garments, it's not always a completely "yarn to apparel" process. Some finishing steps, such as minor trimming or the addition of closures, might be required. However, it significantly reduces the reliance on traditional cut-and-sew methods, streamlining production and minimizing waste. But the fact is, 3D weaving has the potential to reduce excess clothing in several ways. First, it helps in on-demand manufacturing which means producing garments only when needed that minimizes overstocking and waste. It also helps in customization and encourages consumers to invest in longer-lasting, personalized garments instead of disposable fashion. The seamless construction and high-performance materials increase garment lifespan. And 3D woven fabrics from recyclable materials can be more easily repurposed or broken down for reuse.

Startips, brands show the way

Many startups and brands are exploring the potential of 3D weaving. For example, Ministry of Supply, uses 3D knitting technology to create seamless, responsive apparel. Similarly, Unspun develops custom-fit jeans using 3D weaving technology. Twine Solutions offers innovative 3D weaving solutions for technical textiles and composites.

While still in its early stages of adoption, some apparel brands are incorporating 3D weaving into their production. Adidas for example utilized 3D knitting for its Future craft footwear line. And Nike employed Flyknit technology (a form of 3D knitting) in various footwear and apparel products.

Indeed 3D weaving is a promising technology with the potential to transform various industries, including fashion. While challenges remain in terms of cost and scalability, ongoing innovations and increasing adoption suggest a bright future in textile and apparel sector. As R&S continue, more creative and impactful applications of 3D weaving are expected to emerge in future.

A recent report by the United States International Trade Commission (USITC) highlights a significant shift in global apparel sourcing strategies, with India emerging a preferred destination for US buyers. This trend is driven by growing concerns about the garment sector in Bangladesh, coupled with India's increasing credibility as a reliable and stable sourcing partner.

India's rise

The USITC report highlights India's political stability as a crucial factor for US buyers, ensuring confidence in production and delivery timelines. "Brands are more willing to source high-value or fashion items from India compared to less politically stable countries," the report states. This sentiment is echoed by industry stakeholders in India who anticipate a rise in orders, despite the domestic market currently consuming 80 per cent of production.

Besides political stability what works for India is the vertical integration of the textiles sector. India's cotton garment sector benefits from a strong domestic supply chain, thus increasing its appeal as a reliable supplier. The report also recognizes India's specialization in high-value, skill-intensive apparel, dispelling the notion of it being solely a cost-efficient producer. Labor costs and scalability are another plus for India. High labor costs, smaller production units, and expensive logistics pose challenges to scalability. However, on the down side, the limited capacity for manufacturing man-made fiber (MMF) garments restricts India's growth potential in this segment.

Table: A comparative analysis of countries

Country 2013 US Apparel import share (%) 2023 US Apparel import share (%) Key strengths Key challenges China 37.7 21.3 Cost-efficiency, large-scale production Rising labor costs, trade tensions, geopolitical concerns Vietnam 10 17.8 Competitive labor costs, government support, proximity to China Potential over-reliance on China for raw materials Bangladesh 6.3 11.4 Low labor costs, established garment industry Political instability, labor rights concerns, infrastructure limitations India 4 5.8 Political stability, vertical integration, high-value products Labor costs, scalability challenges, limited MMF capacity

Perspectives from key players

India: Industry players are optimistic about the potential increase in orders. Mithileshwar Thakur, Secretary General of the Apparel Export Promotion Council, says the USITC report "has busted the myth by projecting the Indian apparel industry as one specializing in high value-added products."

Bangladesh: The garment sector in Bangladesh is facing challenges due to political instability and rising costs. This has led to concerns about losing market share to competitors like India.

China: China's dominance in the US apparel market has diminished significantly, with its share dropping from 37.7 per cent in 2013 to 21.3 per cent in 2023. Rising labor costs and trade tensions have contributed to this decline.

Vietnam: Vietnam has emerged as a major beneficiary of the shifting landscape, with its share in US apparel imports increasing from 10 per cent to 17.8 per cent over the past decade. Its competitive labor costs and favorable trade agreements have given a growth boost.

The USITC report underscores a dynamic shift in global apparel sourcing, with India gaining prominence as a reliable and high-quality supplier. While challenges remain, India's strengths in vertical integration, political stability, and high-value production position it to capitalize on this evolving landscape. However, addressing labor costs, scalability issues, and expanding MMF capacity will be crucial for India to solidify its position as a leading apparel sourcing hub.

Crystal International Group Limited has launched its Crystal Sustainability Vision 2030 (CSV2030), outlining an ambitious roadmap for sustainable development in garment manufacturing. Building on 17 years of sustainability achievements, CSV2030 sets goals across eight impact areasclimate, circularity, water, biodiversity, wellness, equity, employee engagement, and community partnershipsto address pressing global sustainability issues.

Following the completion of three cycles of its 5year Global Sustainability Targets, Crystal International's CSV2030 reflects an enhanced commitment to environmental and social responsibility. The initiative aligns with the UN Sustainable Development Goals and includes factory-specific actions on a structured timeline to ensure effective implementation.

Crystal’s CSV2030, guided by the tagline ‘Impact for Better,’ highlights its resolve to drive a positive change industry-wide. The plan’s development involved input from stakeholders, thorough industry best-practice analysis, and a review of global sustainability trends. Commenting on this milestone, Catherine Chiu, Vice President of Corporate Quality and Sustainability, expressed confidence in Crystal’s ability to lead sustainable fashion advancements by collaborating with industry partners.

As it embarks on this new chapter, Crystal International is preparing a series of communications to underscore its dedication to sustainability and its commitment to making a meaningful, lasting impact.

Syre, an innovative textile recycling start-up, aims to ‘decarbonize and dewaste’ the textile sector, starting with polyester. Committed to advancing textile-to-textile recycling on a large scale, Syre’s mission is to shift the textile industry from linear to circular processes by converting textile waste into reusable materials. By 2032, the company plans to establish 12 production plants, producing over 3 million metric tons of circular polyester annually, and reducing carbon emissions by more than 15 million metric tons.

In recognition of its impact, Syre received the ITMF Start-up Award 2024 during the ITMF Annual Conference held in Samarkand, Uzbekistan. ITMF Director General Christian Schindler noted that Syre’s membership enhances industry-wide collaboration, which is crucial for scaling circularity and recycling efforts across the textile value chain.

Syre’s Sustainability & Public Affairs Director, Stina Billinger, emphasized that joining ITMF provides valuable access to seasoned textile companies, enabling the start-up to connect, learn, and accelerate its recycling initiatives. Access to ITMF’s resourcesincluding conferences, workshops, and publications further strengthens Syre’s strategic position within the industry.By leveraging ITMF’s network, Syre is set to contribute significantly to sustainable textile solutions, with the goal of reducing waste and emissions industry-wide.

Benin is rapidly evolving as a textile and clothing hub in West Africa, focusing on sustainable cotton production for the global market. The Aid by Trade Foundation (AbTF), through its Cotton made in Africa (CmiA) initiative, is playing a vital role in fostering this transformation, helping Benin’s cotton producers gain access to international markets.

A significant milestone in Benin’s textile growth is the construction of a textile production center near Cotonou, utilizing 100 per cent CmiA-verified cotton. GerlindBaz, senior project manager at AbTF, highlighted the importance of this development during a recent visit, emphasizing CmiA’s contribution to the region’s sustainable textile production. The CmiA standard, which verifies 30 per cent of Africa's cotton production, operates in 11 sub-Saharan countries and supports around 900,000 small-scale farmers.

In early October, marking World Cotton Day, a delegation from AbTF, alongside representatives from GIZ and PAN UK, visited Benin. The team observed CmiA Organic cotton farms in Aklampa, meeting farmers in the Growing Benin’s Organic Cotton Sector project. Managed by PAN UK and OBEPAB and funded by partners including AbTF and Paul Reinhart AG, the initiative aims to support farmers transitioning to organic cotton, positively impacting approximately 45,500 residents.

The project seeks to bolster Benin’s organic cotton industry, ensuring market access and fostering resilience against climate challenges through sustainable practices.

The American Association of Textile Chemists and Colorists (AATCC) has appointed Gregg Woodcock as its new Executive Director, beginning November 11. A graduate of the Philadelphia College of Textiles and Science and the Institute of Textile Technology, Woodcock has built a notable career in textiles, starting with Burlington Industries and advancing to his current role as Senior Manager of Product Quality/Safety at Hanes brands Inc.

An active AATCC member, Woodcock has led and contributed significantly to research committees. Currently, he chairs the RA88 committee on Home Laundering Technology and frequently speaks at AATCC workshops, including the recent Textile Testing Workshop for Specifiers.

Woodcock will assume the role from John Y. ‘Jack’ Daniels, who temporarily returned as Executive Vice President after Diana Wyman’s departure. Daniels, who served over 20 years in AATCC’s leadership, will be named Executive Vice President, Emeritus and will continue on select committees. AATCC expressed its gratitude to Daniels for facilitating a smooth leadership transition.

Birla Cellulose, part of the Aditya Birla Group’s Grasim Industries, has formed a strategic partnership with Circ, a US based recycling innovator, to advance recycled fibre production in textiles. Through this five-year agreement, Birla Cellulose will procure up to 5,000 tons of Circ's pulp annually from its first commercial-scale plant. The recycled pulp will be processed into lyocell staple fibre, reinforcing sustainable practices and supporting Circ’s scale-up efforts.

Circ CEO Peter Majeranowski highlighted the partnership as a significant step forward in promoting circular economies in the fashion industry. Aspi Patel, Chief Technology Officer of Grasim, noted that the collaboration would play a key role in fostering sustainable innovation. Patel emphasized that integrating Circ’s advanced recycling technology with Birla Cellulose's cellulosic fibres strengthens efforts toward building a fully circular economy.

As demand for eco-friendly materials grows, this partnership allows brands to access high-quality recycled lyocell, promoting environmental stewardship. The collaboration underscores the critical role of supply chain cooperation in scaling sustainable solutions amid increasing demand for recycled content.

Aligned on fostering a circular economy, Birla Cellulose and Circ aim to set new standards in textile sustainability, driving down environmental impact through innovative fibre reuse. The partnership is set to enhance the availability of recycled materials, meeting both consumer expectations and industry needs for sustainable solutions.

RE&UP Recycling Technologies has unveiled aninnovative solution to address the global textile waste crisis. Their proprietary technology produces high-quality, durable, and traceable Next-Gen raw materials that compete in cost and performance with both recycled and virgin fibers. This innovation aligns with the Textile Exchange Conference's theme, ‘Case for Change,’ emphasizing the need for resource efficiency and environmental accountability in the textile industry.

Andreas Dorner, General Manager of RE&UP, expressed enthusiasm for participating in this influential event, highlighting the importance of bringing their experience and innovations to a key platform for promoting sustainable practices in the textile industry. The Conference offers RE&UP a valuable opportunity to engage with industry leaders and collaborate on developing best practices for a sustainable future.

As a sponsoring partner, RE&UP aims to demonstrate how its technology can transform pre- and post-consumer textile waste into innovative, durable products. Their recycling process is feedstock agnostic, effectively handling various textile waste, including cotton, polyester, and excelling in polycotton recycling. With this approach, RE&UP is committed to addressing one of the most pressing recycling challenges in the industry, promoting a more circular economy.

At the Textile Exchange Conference 2024 in Pasadena, Eastman highlighted its commitment to sustainability by showcasing Naia Renew ES, a cellulosic fiber made with 60 per cent Global Recycle Standard (GRS)-certified recycled content. Composed of 40 per cent certified recycled waste, 20 per cent recycled cellulose, and 40 per cent sustainably sourced wood pulp, Naia Renew ES is gaining traction with eco-conscious brands like Reformation, as it supports high sustainability standards without compromising style or quality.

Eastman’s innovative carbon renewal technology underpins Naia Renew fibers, breaking down waste to molecular building blocks to create traceable, biodegradable fibers that reduce reliance on virgin materials. This process is helping Eastman set new industry standards in circularity, offering brands a ‘Runway-Ready’ solution that meets environmental goals with fashion-forward looks.

Eastman’s ‘Recycled and Runway Ready’ showcase at Booth 18 highlights collections made from recycled content, creatively displayed through AI-enhanced photography. This exhibit emphasizes Eastman's aim to bring sustainable beauty to mainstream fashion and inspire consumer choices.

In collaboration with partners like Debrand and Patagonia, Eastman is pioneering textile-to-textile recycling, demonstrating how pre- and post-consumer waste can be transformed into new garments. Furthermore, Eastman fosters sustainability in fashion education, engaging institutions like Barcelona’s Escola Superior de Disseny and the Beijing Institute of Fashion Technology to prepare the next generation of eco-focused designers.

Eastman’s Carolina Sister Cohn will join leaders from Circ, Circulose, and Syre for a panel on October 31st, addressing how textile innovation can drive widespread adoption of sustainable solutions.

Pacific Jeans Ltd, a leading denim manufacturer, will showcase its latest sustainable collections at the Denim Lounge during the 17th Bangladesh Denim Expo, scheduled for November 4-7 at ICCB’s Hall-4 in Dhaka. Known for its world-class denim since 1984, Pacific Jeans has become a key supplier for major fashion brands worldwide, exporting to over 50 countries.

Committed to innovation and sustainability, the company aligns its practices with the UN Sustainable Development Goals, underscoring a responsible approach in the global apparel supply chain. Its LEED certification further reflects this dedication, establishing Pacific Jeans as a frontrunner in ethical manufacturing.

At the Denim Lounge, Pacific Jeans will showcase a collection that blends innovative design, functionality, and sustainability, highlighting Bangladesh's advancing role in denim innovation. Syed M Tanvir, Managing Director of Pacific Jeans Ltd, noted that participating in the Bangladesh Denim Expo offers a platform to display the strengths of Bangladesh’s denim industry to an international audience, with an aim to establish the country as a leading force in the global denim supply chain.

Pacific Jeans has previously showcased its design and technological achievements at Bangladesh Denim Innovation Nights and represented Bangladesh at the Best of Bangladesh event in the Netherlands in 2022. The Bangladesh Denim Expo, organized by the country’s apparel industry, is held biannually and focuses on advancements in sustainable fabric technology, furthering the nation's position as a leader in responsible fashion.