FW

The Intertextile Shanghai Apparel Fabrics – Autumn Edition 2025, held from September 2-4 at the National Exhibition and Convention Center (Shanghai), has concluded, leaving an indelible mark on the global textile industry. It was more than a trade fair; it was a dynamic platform that set new standards for sourcing, innovation, and collaboration. From upgraded zones to a comprehensive fringe program, the fair provided a holistic experience that addressed the evolving needs of the market. This review delves into the key highlights, new features, and overall impact of this landmark event.

With over 3,700 exhibitors from 26 countries and regions, the event was a vibrant hub of textile and apparel professionals, all united by the common goal of shaping the future of fashion. The fair's success was further underscored by the welcoming of eight buyer delegations from seven countries and regions, which included 350 arranged meetings for 50 VIP buyers, reflecting a strong commitment to facilitating impactful business opportunities.

Redefined Zones and Curated Displays: A seamless sourcing journey

One of the most remarkable aspects of this year's fair was the strategic enhancement of its various zones, each meticulously curated to cater to specific market segments. The organizer, Messe Frankfurt, successfully transformed the exhibition into a series of focused experiences, allowing buyers to navigate the vast show floor with unparalleled efficiency. As Wilmet Shea, General Manager of Messe Frankfurt (HK) Ltd., aptly noted, the fair is designed to proactively respond to the evolving needs of the global apparel industry, and the upgraded zones are a testament to this commitment.

The Functional Lab and The CUBE

In Hall 4.1, the Functional Lab was a testament to the surging demand for activewear and technical textiles. This zone showcased a comprehensive selection of innovative fabrics, including smart textiles, outdoor materials, and sports textiles. Exhibitors like Burlington and Unifi Textiles (Suzhou) presented their cutting-edge offerings, emphasizing the fusion of performance and style. The dedicated display area, The CUBE, was a particular highlight, providing a tangible showcase of advanced fabrics and accessories, from moisture-wicking materials to protective apparel. This focused area gave buyers a hands-on opportunity to assess materials that merge innovation with functionality, crucial for athleisure and high-performance garments.

Premium Wool and the debut of Bespoke Performance

The Premium Wool Zone was a sanctuary for luxury and sophistication. Esteemed European exhibitors, including Abraham Moon & Sons and Scop Clarenson, showcased their latest collections, catering to the discerning tastes of high-end designers and tailors.

A significant upgrade was the new Bespoke Performance display area, which replaced the former Functional Suiting Display Area. This new zone masterfully bridged the gap between traditional luxury and modern functionality. As explained by Shea, it's a response to the "increasingly blurry" line between distinct sourcing goals, where consumers now seek performance features in their everyday apparel. The showcase of outfits from the Hong Kong designer brand SUIT ARTISAN perfectly illustrated this synergy of style, practicality, and luxury, offering a fresh perspective on high-end textiles.

A notable success story from this zone was ALUMO AG, a proud winner at The China International Fabrics DESIGN Competition held during the fair. The company was recognized for shirting innovation with three standout fabrics: Cashmerello Light, a lightweight cotton and cashmere blend; Bernina, a polyamide and elastane fabric; and Wunder, a pure cotton quality with natural wrinkle resistance. ALUMO's presence, alongside its partners Brennet and Eugster & Huber, created a curated space of high-quality shirting fabrics, blending Swiss heritage with modern functionality and artistic design.

Innovation & Digital Solutions Zone

Formerly known as the Digital Solutions Zone, the newly named Innovation & Digital Solutions Zone was a hub of technological advancement. It highlighted how digital innovations are revolutionizing the textile industry, from design to manufacturing. A major highlight was the presentation of The Green Machine by the Hong Kong Research Institute of Textiles and Apparel (HKRITA), a groundbreaking recycling system for mixed materials that demonstrated eco-conscious advancements in sustainability. The zone also featured Shima Seiki's latest digital fabric simulation software and AiDLab's AI-based fashion design and textile inspection technology. These exhibits weren't just for show; they represented strategic tools for sourcing teams. As Shea pointed out, the strong attendance at related fringe events shows that buyers recognize the intrinsic value of these technologies for reshaping the market landscape. The fair's digital tools, such as the Connect PLUS platform and the Intertextile Hub app, further streamlined the experience by offering AI-driven recommendations and integrated messaging, proving that digital transformation is at the core of effective sourcing.

The debut of Essential Suits & Shirts

One of the most impactful new additions was the Essential Suits & Shirts zone, specifically curated for the ready-to-wear market. This zone answered a clear market need for practical, high-quality fabrics that are both versatile and accessible. Leading exhibitors like Mahmood Textile Mills and Kohinoor Mills showcased their expertise in producing fabrics that are suitable for both formal and casual environments. Mahmood Textile Mills' commitment to sustainable production methods resonated with the market's demand for eco-friendly textiles, while Kohinoor Mills' innovative approach to weaving, dyeing, and finishing highlighted the balance of style and comfort. This zone filled a crucial gap, providing a focused avenue for buyers seeking adaptable materials for the modern wardrobe.

A Global Meetingpoint: Country pavilions and exhibitor excellence

The fair's international scope was a key differentiator, attracting exhibitors and buyers from across the globe. The presence of nine country and region pavilions—from Italy (Milano Unica) and France to India, Japan, and Türkiye—underscored the event's status as a global meeting point. These pavilions served as condensed showcases of national textile prowess, allowing buyers to efficiently explore the diverse offerings of different regions.

Pakistan underscored its ambition to expand its footprint in the global textile market with a strong showing, fielding 10 exhibitors across the two events—seven at Intertextile Shanghai Apparel Fabrics and three at Yarn Expo. According to Muhammad Abdullah Tanvir, Deputy Marketing Manager at Diamond Fabrics Limited, "Intertextile Shanghai is the right platform for expanding our global reach; it attracts the right audience and gives us an excellent opportunity to showcase our products."

Meanwhile, Bangladesh continued its strong presence at the fairs, with four companies.The exhibitors expressed optimism about the fair's role in building new business relationships. Luthfor Rahman Munna, Senior Marketing Manager at Square Textiles PLC, said the fair offered a "remarkable experience," while Rabi from Amanat Shah Fabrics Ltd. highlighted its value as a hub for expanding international networks, noting that the company has consistently benefited from its participation over the years.

Beyond the pavilions, a roster of new and returning exhibitors contributed to the fair's rich tapestry of innovation. Itochu Corporation (Japan) demonstrated a commitment to a circular economy with its coffee grounds-based garments and eco-friendly dyes. Fibrant (Netherlands), a pioneer in sustainable nylon solutions, showcased its EcoLactam line with a "world-class carbon footprint," highlighting the industry's push towards greener materials. The inclusion of new exhibitors like Wendler Einlagen (Germany), reinforced the fair's emphasis on quality and sustainability.

The group pavilions, organized by industry giants like Lenzing, LYCRA, Hyosung, and Sorona, were another highlight. These collective displays shone a spotlight on specific innovations. For example, within the Lenzing Group Pavilion, Dezhou Huayuan Eco-Technology introduced a revolutionary ultra-fine denier fiber, 10% finer than cashmere, perfect for skin-friendly intimate apparel. Meanwhile, Quanzhou Lianxingfa Knitting in the LYCRA Group Pavilion demonstrated its expertise in elastic materials for sportswear, and Siris (Ganglong) Knitting in the Hyosung Group Pavilion showcased its vertically-integrated supply chain and global reach, supplying major brands like Calvin Klein and Nike.

Texpertise Econogy: Driving sustainable transformation

The fair's unwavering commitment to sustainability was front and center, championed by the Texpertise Econogy initiative, which built on the success of previous editions. The Econogy Tour in Hall 5.1 provided guided visits to eco-focused exhibitors, led by an independent consultant who facilitated in-depth discussions about the latest innovations in green textiles. This interactive experience was complemented by insightful Econogy Talks, including:

● Impact Now, building greener and Low-Carbon sustainable development supply chains: This seminar, presented by SGS-CSTC Standards Technical Services, demonstrated practical strategies for creating a greener and low-carbon textile industry. It covered crucial aspects such as optimizing recycling materials, sustainable chemical management, low-carbon emission reduction designs, and improving ESG (Environmental, Social, and Governance) performance, offering a roadmap for a more sustainable supply chain.

● Ecodesign for Sustainable Products Regulations (ESPR): Bureau Veritas presented vital information on how companies can navigate and comply with the increasingly prominent EU regulations for sustainable products. Their services, including eco-design solutions, life cycle assessments, and environmental product declarations (EPD), were detailed, providing attendees with critical knowledge for promoting a green transition and circular economy strategy.

The Econogy Hub featured a stringent vetting process known as Econogy Check, which pre-qualified suppliers based on their comprehensive sustainability credentials. This initiative received overwhelmingly positive feedback from buyers, who noted that it saved them significant time and money by pre-qualifying suppliers and building trust in the authenticity of green product sources.

A Comprehensive Fringe Programme: Unpacking the future of fashion

The fringe program was a captivating and essential component of the fair, offering a roundup of the industry's most pressing topics. With 37 seminars and a curated lineup of expert-led discussions across four key themes, the program provided attendees with unparalleled insights and a competitive edge in the fast-evolving fashion landscape. The meticulously planned schedule, available through a comprehensive online event calendar, allowed fairgoers to optimize their engagement. Highlights of the fringe program were a key feature of the show, with events specifically designed to supplement the exhibition's offerings and provide expert-led insights.

Market Information & Business Strategies: Global perspectives and opportunities

The fair also provided critical market insights and strategic guidance:

● Opportunities in ASEAN in a changing trade environment: The ASEAN Federation of Textile Industries (AFTEX) hosted a dynamic forum where industry representatives from across the region shared invaluable market insights and analyzed emerging trends. Attendees engaged in dialogue, strengthened partnerships, and deepened their understanding of ASEAN's evolving textile landscape, particularly pertinent given the "China + 1" sourcing strategy.

● Overview of the UK textile industry and opportunities for the future: The UK Fashion and Textile Association (UKFT), a preeminent industry association, provided a perceptive analysis and various business insights relating to the UK’s textile sector. This session offered a unique perspective on a key global market and highlighted potential business opportunities for international partners.

These sessions, featuring discussions led by WGSN, AFTEX, HKRITA, and the OEKO-TEX Association, empowered attendees with the knowledge to discover and tap into new markets and navigate complex trade environments. As Shea emphasized, the strong attendance at these strategic fringe events underscored their critical value to serious sourcing teams.

The fair's success was also noted by attendees like menswear designer Rudy Fontaine from Celio, who described his two days at the fair as full of "lots of ideas and exciting projects ahead," highlighting the event's role as a source of inspiration and a platform for future innovation.

Technology & Solutions: The digital frontier of textiles

The Technology & Solutions category was packed with forward-thinking discussions, highlighting the transformative power of digital innovation:

● Enhancing fashion & textiles through Human-AI interaction: Professor Calvin Wong, CEO & Centre Director of AiDLab, introduced their innovative AI-based technologies. This included AiDA for fashion design, which enhances creativity and efficiency in the design process, and WiseEye for textile inspection technology, which drastically improves quality control. The seminar showcased how human-AI collaboration is driving significant advancements in the textile industry.

● New Era of Digital Fabric: End-to-End DPC solution: This session focused on Shima Seiki’s cutting-edge digital product creation (DPC) solution. Its design software, a key component, enables true-to-life fabric simulation seamlessly integrated with physical production. The presentation explained how this technology is becoming the new standard for digital product creation, significantly shortening lead times and reducing physical sampling cycles, a benefit that world-leading retailers like Decathlon have already successfully implemented.

Design & Trends: Shaping tomorrow's aesthetic

The Design & Trends category was a major draw, offering a visionary look into future fashion directions. The Intertextile Directions Trends Autumn / Winter 2026-27 seminar, led by Michael Bonzom, Creative Director of NeIlyRodi Agency, brought to life the compelling theme "PUSH SENSATION." This session delved into the wildest dreams of humankind, exploring paradoxes such as gentle versus raw, and classic versus theatrical, through a creative and inspiring display of on-trend fabrics and accessories. Bonzom also guided attendees through immersive Trend Forum Tours, providing deeper insights into the showcased materials.

Complementing this, Benedicte Peaudecerf, Style Designer and Trend Forecaster at PeclersParis, presented the FW26/27 Women's Fashion Trend Forecast, offering essential inspiration and guidance through a comprehensive and detailed outlook for the upcoming seasons.

Observations from attendees further confirmed the fair's impact. Wendy (Xuejin) Jin, CEO of Dalian Liren Smile Fashion Co., LTD., noted exciting trends in the faux fur market, a key area of their business. She observed that faux fur is undergoing a revolution, becoming more washable, achieving a quality closer to natural fur, and enabling new design possibilities like patchwork. Her experience at the fair reinforced the company's ability to act as a fully integrated garment manufacturer, connecting with excellent suppliers to provide seamless service from fabric sourcing to production and export.

A confluence of value chains

The co-location of Intertextile Shanghai Apparel Fabrics with Yarn Expo Autumn, CHIC, and PH Value created a comprehensive spectacle for the entire apparel textile value chain. This strategic alignment, especially with Cinte Techtextil China, allowed buyers to explore a full spectrum of textiles, from apparel fabrics to technical textiles, in a single trip. The event’s success, as evidenced by the high number of exhibitors and international delegations, solidifies its position as a global leader in the textile industry. It was an event that did more than showcase products; it fostered dialogue, forged partnerships, and provided the tools necessary for the industry to navigate a rapidly changing world. The 2025 edition proved that in the fast-paced world of textiles, staying connected to innovation and collaboration is not just an option—it’s a necessity.

The just concluded annual Global Fibre Conference in Dornbirn put forth a complex picture of the synthetic fibre industry. While the conference highlighted overcapacity and the economic fallout of current trade policies, it also showcased promising technical advancements in recycling and biobased fibres, hinting at a future shaped by innovation and sustainability.

A glut of synthetic fibres and economic disruptions

The opening session, dedicated to strategic issues, delivered a sobering assessment of the global market. Overcapacity in synthetic fibres remains a massive problem, with polyester (PIF) and nylon (NIF) production exceeding demand by almost 52 per cent and 29 per cent, respectively. Analysts say, at current growth rates, it would take until 2050 to absorb the existing capacity, suggesting that a sustained increase in prices is highly unlikely.

Adding to the market's woes, current US tariff policies are guaranteed to cause price hikes, particularly for American consumers, while also leading to widespread disruptions and supply chain shifts. For example, a recent Crisil Ratings analysis revealed Indian home textile manufacturers are bracing for a 5-10 per cent decline in revenue and a drop in operating profits due to the 50 per cent US tariff imposed on August 27.

The conference also raised concerns about global climate policies, with Prof Radermacher an expert, noting that the current approach of concentrating decarbonization efforts in industrialized nations is both costly and ineffective, underscoring a fundamental disconnect between environmentalism and sustainability.

Recycling vs. biobased, a race to scale

The technical sessions provided a more optimistic outlook, focusing on cutting-edge research in recycling and biobased fibres. Many players showcased their technical progress across all textile-to-textile recycling methods, mechanical, thermo-mechanical, chemical, and enzymatic. However, some hurdles remain before these technologies can achieve industrial scale. Challenges include a lack of sustained demand, an inability to compete on cost with virgin fibres, questions about total process yield, and a lack of common feedstock and recyclate standards.

A particularly hot topic was the future of bottle-to-fibre recycling. While it has been a common practice, the conference highlighted that it is now under pressure. The packaging industry, which uses one-third of global PET, is failing to meet its own recycling targets, creating competition for recycled PET (rPET). This competition, combined with the fact that two-thirds of all PET goes to fibre production, suggests that relying on bottles as a feedstock is not a sustainable, long-term solution. The textile industry will need to establish its own circular supply chain based on its own waste.

In contrast, biosynthetics emerged as a strong contender for a faster path to market. These "drop-in" solutions can be integrated into existing manufacturing processes, bypassing many of the challenges plaguing recycling, such as high capital expenditure and quality issues. They also boast of superior Life Cycle Assessment (LCA) values, particularly when compared to chemical recycling.

The conference focused on biobased textiles, including man-made cellulosics (MMCFs), which are highly versatile and use renewable feedstock. There was also a notable presence from the cotton and wool industries, challenging outdated myths about their environmental footprints. Overall, a major takeaway was the need to ensure that the inevitable volume growth of global fibre production is not exclusively absorbed by synthetics.

Innovations and future

Beyond the main sessions, the conference covered other critical topics, including microplastics (or fibre shedding), safe chemicals management, and new innovations for protection and defense markets. The diversity of topics and the opportunity for one-on-one discussions highlighted the event's role as a vital hub for industry knowledge.

The conference also celebrated the next generation of innovators, with a special shout-out to Ing Leonie Beek, was awarded the prestigious Paul Schlack Prize for her groundbreaking research on oil-absorbing biomimetic textiles. Beek, a researcher at the Institute of Textile Technology (ITA) at RWTH Aachen University, developed a "Bionic Oil Adsorber" (BOA) that can separate oil from water without external energy or chemicals, a technology inspired by the water fern Salvinia molesta. (Source: Dornbirn GFC, SciProfiles)

To sum up the Dornbirn Global Fibre Conference remains the premier venue for understanding the current state of the fibre industry and anticipating which innovations will be market-ready in the near future. While some presentations are highly technical, they are always framed within the context of market trends and sound industry logic, making it an essential event for anyone in the textile sector.

When the US government moved to terminate the long-standing de minimis exemption, the duty-free threshold for low-value imports, it sent a tremor through America’s small business ecosystem. For decades, the rule allowed shipments valued under $800 to enter the country without tariffs or burdensome paperwork, a lifeline for small retailers and niche importers. Now, with its removal, the shock is reverberating most acutely through the fashion and apparel industry, where margins are slim and reliance on small-batch imports is common.

Fashion and apparel sector on the edge

For Peri Olson, founder of Diesel and Lulu’s, a boutique importing premium European apparel, the change has been nothing short of a nightmare. Olson says they are taking it day by day now and they have to absorb a good deal of the costs while waiting it out to see what happens, but they can’t absorb it all. Her experience reflects a broader reality. Small-batch imports once a competitive advantage for niche labels and artisan boutiques are now saddled with tariffs, increased compliance costs, and delayed shipments. Fashion startups that thrived by bringing in unique styles from Italy, France, or the UK face a new calculus: either raise prices, cut staff, or risk closing down.

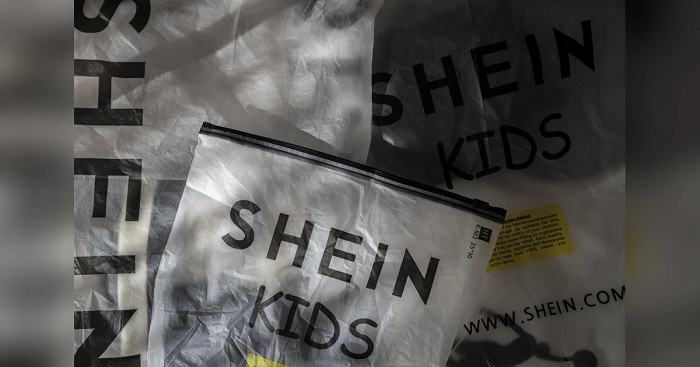

Meanwhile, large e-commerce giants like Shein and Temu often criticized for exploiting de minimis loopholes are finding ways around the rules by bulk-shipping into the US and redistributing domestically. The irony isn’t lost on small business owners: while the policy shift was partly aimed at curbing fast-fashion imports, it may end up hurting American entrepreneurs more than the overseas titans it was meant to target.

The broader economic fallout

Small businesses are not just the heart of Main Street America; they are a pillar of the national economy. They employ nearly half of the American workforce and contribute over 40 per cent of US GDP. The end of de minimis threatens to squeeze these businesses on multiple fronts. First is job losses as rising costs may force owners to reduce staff, scale back hours, or shut down. Also consumers will see higher prices as duties and shipping costs are passed down. And communities that rely on small businesses could see reduced local spending power and weakened retail ecosystems. The scale of de minimis usage underscores how significant its removal is.

Table: Impact of de minimis removal

|

Metric |

Value (FY 2024) |

|

Total shipments under de minimis |

1.36 billion |

|

Declared value of de minimis imports |

$64.6 billion |

|

Share from China |

73% |

|

Top other origins |

Canada, Mexico, UK |

Source: U.S. Customs and Border Protection, 2024

The removal has led to several winners and losers. For example, Diesel and Lulu’s facing increased shipping costs and duties on small-batch European imports are absorbing costs in the short term but are unsure of long-term survival. Merchant & Mills, a British fabric and pattern company, has already been forced to raise US retail prices by 15 per cent to offset duties. Shein & Temu the e-commerce giants are navigating around restrictions by bulk importing, potentially gaining even greater advantage over smaller rivals.

Why the de minimis door was shut

The decision to eliminate the exemption comes amid a heated political debate. Both Democrats and Republicans have criticized de minimis as a loophole that disproportionately benefited Chinese e-commerce giants. In 2023, bills such as the Import Fairness Act gained traction, targeting Shein and Temu by name. US Customs and Border Protection (CBP) too warned that the sheer volume of de minimis packages over 1 billion annually was overwhelming inspection capacity, creating risks of unsafe or counterfeit goods slipping through. Meanwhile domestic manufacturers, unions, and textile associations pushed for reform, arguing that unchecked duty-free imports undermined US jobs. Yet critics argue that the policy was applied too broadly. Instead of narrowly targeting high-volume importers exploiting the system, it hit small businesses importing in good faith.

“It’s like using a hammer when what you needed was a scalpel,” said Amy O’Neill, a Washington-based trade policy consultant.

However, industry analysts warn that the burden will fall heaviest on America’s smallest players. “Small businesses are the first to feel the effect, and they feel it the most acutely, but that effect does trickle down to the wider economy,” says Jacob Bennett, CEO and cofounder of Crux Analytics. “The paperwork sounds difficult now, but this will get normalized, and ultimately you’ll still be left with the increased cost,” added Martin Balaam, CEO of Pimberly. The consensus therefore is that even as businesses adapt to the administrative side of the change, the financial weight will remain.

In response to the growing threat of heatwaves, researchers at The Hong Kong Polytechnic University (PolyU) have developed next-generation personal cooling solutions including iActive Intelligent Sportswear, a garment that uses artificial ‘sweat glands’ to quickly eject perspiration, keeping skin dry and removing sweat up to three times faster than a person's peak sweating rate.

The second technology is called Omni-Cool-Dry which is a breathable, skin-like fabric that reflects solar radiation and emits body heat, lowering skin temperature by about 5°C compared to conventional fabrics.

Thermo-adaptive soft robotic garment which uses temperature-responsive actuators to adjust insulation, keeping its inner surface up to 10°C cooler than standard gear in temperatures reaching 120°C and lastly, a non-invasive wearable SweatMD that uses a microfluidic network to analyze sweat and track biomarkers like glucose and potassium, providing real-time health insights on a smartphone.

These innovations form a complete AI-ready ecosystem, with sensors gathering data and intelligent clothing responding with targeted actions. The work has earned significant international recognition, including a Gold Medal at the 2025 Geneva Invention Exhibition and The Fiber Society's Distinguished Achievement Award for Professor Dahua Shou, Limin Endowed Young Scholar in Advanced Textiles Technologies, Associate Professor of the PolyU School of Fashion and Textiles, Associate Director, Research Centre of Textiles for Future Fashion, and Associate Director, PolyU-Xingguo Technology and Innovation Research Institute. The PolyU team’s goal is to bridge the gap between fundamental research and real-world applications to address global challenges.

Luxury sales in India are experiencing double-digit growth as the number of high-income households in India is projected to double by 2030. This demographic shift, combined with rising disposable incomes, is fueling a strong appetite for luxury goods and experiences.

Luxury brands are increasingly creating exclusive products and collections tailored to Indian tastes and cultural events. For example, some watch brands are launching India-inspired timepieces, and luxury porcelain houses are creating sculptures of religious figures.

India's vibrant festive and wedding seasons are a major catalyst for luxury spending. The high number of auspicious wedding dates in 2025 has created a significant opportunity for luxury fashion houses, jewelers, and other high-end brands.

The luxury real estate market is also booming, with sales of homes priced at Rs 4 crore and above increasing by 85 per cent in H1, FY25. This reflects a growing consumer confidence and a desire for premium living. While major cities like Delhi and

Mumbai remain luxury hubs, brands are increasingly expanding into Tier-I and Tier-II cities. E-commerce platforms are also playing a crucial role by making luxury goods accessible to consumers in smaller towns.

Younger, affluent consumers, including Gen Z, are driving a new trend. They are not just buying products but are also investing in luxury experiences and ‘quiet luxury,’ which focuses on quality and craftsmanship rather than overt branding.

Overall, the luxury market in India is poised for a record-breaking year. It's a key growth engine for global luxury brands looking to expand their presence, especially as other major markets like China face a slowdown.

The European Union has launched an anti-dumping investigation into imports of PET Spunbond fabrics from China.

The investigation was initiated after a complaint was filed on August 8, 2025, by two companies, Freudenberg Performance Materials and Johns Manville (JM). They allege, Chinese imports of this product are being ‘dumped’- sold at unfairly low prices- which are causing significant harm to the European Union's domestic industry.

The product in question is a specific type of non-woven fabric made from polyester filaments. It's used in various applications and is defined by its thickness (between 0.5 mm and 1.8 mm) and weight (more than 70 g/sq m), among other technical specifications.

The complainants claim, it's inappropriate to use China’s domestic prices and production costs for comparison because of ‘significant distortions’ in the Chinese market. They cite a 2024 Commission document on market distortions in China, pointing to issues with land, energy, capital, raw materials, and labor, particularly within the textile industry.

To support their claim, they provide extensive evidence, including numerous Chinese government policy documents and five-year plans, such as the ‘Made in China (2025)’ initiative. These documents show a pattern of state intervention and support that distorts the market, they argue.

As a result, the Commission will not use Chinese domestic prices to determine a fair value. Instead, it will construct a ‘normal value’ for the product based on undistorted prices from a representative country. The complainants have suggested Turkey and Thailand as potential benchmarks.

The evidence provided by Freudenberg Performance Materials and JM suggests that the low-priced Chinese imports have negatively impacted the European industry. They claim. this has led to a drop in sales, lower prices, and a decrease in market share for European manufacturers, causing substantial harm to the industry's financial health and overall performance.

Fashion designer Christian Siriano brought a touch of cinematic magic to New York Fashion Week, transforming the athleisure section of a Macy’s store in Herald Square into a runway. His Spring 2026 collection took the audience on a journey from black-and-white to full Technicolor, inspired by old Hollywood.

The star-studded front row was a reflection of the theme, with Whoopi Goldberg and Oprah sitting alongside singer Lizzo. The show opened with longtime Siriano muse Coco Rocha, who strutted down the catwalk in a striking black-and-white striped and polka-dot organza blazer with a matching skirt and hat.

Siriano said his collection was inspired by actress Marlene Dietrich and her style, which effortlessly blended masculine and feminine elements. The show began with black-and-white looks featuring a variety of textures, including sequined plaid, polka dots, and stripes. The collection then shifted dramatically, as if a film had suddenly burst into color, with pieces like a vibrant Tiffany blue ball gown and a Barbie pink deconstructed tuxedo dress.

Models' hair was styled in slick buns with a single pin curl, maintaining the old Hollywood glamour. In a modern twist, some structured blazers were paired with nothing but tights. The collection featured a range of tailored blazers and voluminous bubble dresses, showcasing Siriano's play with patterns and structure.

Beyond the fashion, Siriano continues to be a champion of inclusivity, featuring models of all sizes, genders, and backgrounds. He says, it’s just important to have a mix of beautiful people.

Reports from multiple sources indicate, Francesca Bellettini, Deputy CEO, Kering, is expected to be appointed as the new CEO, Gucci. This change in leadership comes less than a year after Stefano Cantino took the helm, signaling an urgent effort by Kering to stabilize and revitalize its most crucial brand.

Historically accounting for nearly half of Kering's total sales, Gucci has been facing significant challenges. The brand's performance has faltered, with sales declining by 21 per cent in FY24 and a further by 25 per cent in H1, FY25. This prolonged weakness has become a major concern for Luca de Meo, CEO, Kering, who sees a swift turnaround at Gucci as his most important task. The decision to replace Cantino so quickly underscores the immense pressure to deliver immediate results in a highly competitive luxury market.

Bellettini is widely regarded as one of the most accomplished and trusted executives in the luxury industry. Her appointment is a strategic move to leverage her proven track record of success. She is credited with the incredible revitalization of Saint Laurent, where she served as CEO for over a decade. During her tenure, she grew the brand's revenue sixfold, transforming it into a major powerhouse within the Kering portfolio.

Bellettini is also known for her ability to balance a clear creative vision with strong commercial discipline, a skill that is seen as essential for Gucci's turnaround. The timing of her appointment is critical. It comes just weeks before Denma, new Creative Director is set to debut his vision for the brand in Milan on September 23. Bellettini was closely involved in bringing Demna to Gucci, and her leadership ensures a seamless and coherent alignment between the brand's creative and business strategies.

This move is one of the first major decisions by Meo, and signals a decisive shift toward stabilizing the group's biggest asset. The urgency is so high that Kering has reportedly postponed its plans to acquire the remaining stake in Valentino to focus its energy entirely on Gucci's recovery. Bellettini's mission will be to restore Gucci's financial health, redefine its brand positioning, and rebuild the cultural relevance that made it a global icon.

A major shift in European Union policy is set to redefine the global apparel and textile landscape. The EU is moving from a fragmented and voluntary approach to a unified, comprehensive, and binding framework that targets the entire lifecycle of textile products. This new policy, driven by Extended Producer Responsibility (EPR) schemes, is designed to combat fast fashion's environmental impact and promote a truly circular economy. The changes will definitely affect all international brands, including US companies that sell products to European consumers.

The core of the new regulations

The new rules, stemming from the EU's Strategy for Sustainable and Circular Textiles, introduce some major changes outlined in the table below.

Aspect Existing EPR Laws & Frameworks (Before 2025) New 2025 EU Rules EPR Implementation Many EU countries had EPR schemes, causing compliance complexity and market fragmentation. Establishes harmonized, mandatory EPR schemes across all EU member states for textiles. Producers pay full lifecycle costs. Coverage Some Member States had EPR covering textiles partially; scope and fees varied widely. Applies to all textiles and e-commerce sellers, both EU and non-EU based, covering all stages (collection, sorting, recycling). Digital Product Passport (DPP) DPP under Ecodesign Regulation mandates digital product info for sustainability from 2027, but not tied directly to EPR fees. EPR aligned with DPP and eco-modulation to reward circular, durable products; reporting requirements harmonized EU-wide. Fast Fashion & Ultra-Fast Fashion Some countries had voluntary initiatives or partial fees targeted to fast fashion's impact. Explicit provisions allow states to set higher fees targeting ultra-fast fashion, discouraging environmentally harmful practices.

This new framework is a direct response to the alarming amount of textile waste generated in the EU. According to the European Environment Agency (EEA), the average EU citizen consumes around 16 kg of textiles per year, generating 6.94 million tons of textile waste annually.

Data on textile waste

Low recycling rate: Currently, only about 22 per cent of post-consumer textile waste in the EU is collected separately for reuse or recycling.

Landfill and incineration: The vast majority of discarded textiles, approximately 87 per cent, end up in landfills or are incinerated.

Global impact: The EU's high consumption and low recycling rates contribute to the global textile waste crisis, with much of the collected but unsorted waste being exported and often ending up in landfills in African and Asian countries.

The financial and operational impact

|

Aspect |

Existing EPR Laws & Frameworks (Before 2025) |

New 2025 EU Rules |

|

EPR Implementation |

Many EU countries had EPR schemes, causing compliance complexity and market fragmentation. |

Establishes harmonized, mandatory EPR schemes across all EU member states for textiles. Producers pay full lifecycle costs. |

|

Coverage |

Some Member States had EPR covering textiles partially; scope and fees varied widely. |

Applies to all textiles and e-commerce sellers, both EU and non-EU based, covering all stages (collection, sorting, recycling). |

|

Digital Product Passport (DPP) |

DPP under Ecodesign Regulation mandates digital product info for sustainability from 2027, but not tied directly to EPR fees. |

EPR aligned with DPP and eco-modulation to reward circular, durable products; reporting requirements harmonized EU-wide. |

|

Fast Fashion & Ultra-Fast Fashion |

Some countries had voluntary initiatives or partial fees targeted to fast fashion's impact. |

Explicit provisions allow states to set higher fees targeting ultra-fast fashion, discouraging environmentally harmful practices. |

Higher costs: US brands and other international companies selling in the EU, including through e-commerce, will need to register and contribute to EPR schemes in every country they sell to.

Operational changes: Companies will need to invest in new data management and traceability systems to comply with the upcoming Digital Product Passport (DPP). The DPP will act as a digital ID for each textile product, providing information on its composition, production, and end-of-life options via a QR code or similar identifier.

The rise of a circular textile economy

This regulatory push is expected to drive significant investment and innovation. A McKinsey report estimates that scaling up textile recycling in Europe could require €6 billion to €7 billion in capital expenditure by 2030. However, it also projects that a mature textile recycling industry could generate a profit pool of €1.5 billion to €2.2 billion annually and create a total holistic impact of €3.5 billion to €4.5 billion when considering job creation and environmental benefits.

France's head start

France has been a pioneer in this area, having a regulated EPR scheme for textiles since 2007. The French eco-organization Refashion manages the program, and its success is a potential blueprint for the EU-wide system. The French approach, with its eco-modulation fees and mandatory data reporting, has helped the country achieve a 60 per cent reuse and recovery rate for its collected textiles, significantly higher than the European average.

What's next for US brands?

The new EU regulations signal a major shift away from a linear take-make-dispose model. For international brands, this is not merely a compliance issue but an opportunity to embrace circularity. Companies that proactively invest in sustainable design, supply chain transparency, and new business models like rental and repair will be better positioned to meet regulatory demands and gain a competitive edge in a market where consumers are increasingly demanding more ethical and sustainable products. As companies race to adapt, one can expect to see an uptick in demand for professionals in regulatory compliance, sustainability, and reverse logistics in the coming years.

In an effort to boost cooperation with Egyptian companies, Karl Mayer along with 18 leading German textile machinery manufacturers, is on a business trip to Cairo and Alexandria. The company will attend business meetings on September 22 in Cairo and September 24 in Alexandria, with each session featuring a large symposium, B2B networking events, and visits to textile manufacturers.

The trip is being organized by SBS Systems for Business Solutions and the German-Arab Chamber of Industry and Commerce in Egypt, in close collaboration with the VDMA. A renowned manufacturer of warp knitting and warp preparation equipment, Karl Mayer is participating to present itself as a full-service partner for its customers.

The brand’s discussions will focus on the entire package they offer, from after-sales care and customer support to training and development, says Adam Stevenson, Sales Representative, Karl Mayer.

Stevenson describes Egypt as a promising and exciting market for Karl Mayer, noting, Chinese and Turkish textile companies are moving or opening new production facilities in the country. He expressed optimism about meeting new customers and companies interested in entering the knitting sector.