FW

The United States Fashion Industry Association (USFIA) will host the 37th Annual Apparel Importers Trade & Transportation Conference on November 5, 2025, at the Fashion Institute of Technology (FIT) in New York City. The event is co-hosted with FIT’s Jay and Patty Baker School of Business and Technology, International Trade and Marketing Department.

This flagship conference brings together fashion industry professionals from across the supply chain - including sourcing, trade compliance, logistics, marketing, and sustainability - for a full day of insights, networking, and strategic discussion.

According to Julia K Hughes, President, USFIA, this conference is a critical opportunity for industry leaders to stay informed and connected. Leading experts will express their views on tariffs, sourcing diversification, compliance challenges, and opportunities for circularity and sustainability in the supply chain.

Featured sessions will cover Sourcing Outlook and Trends for 2026, Tariffs and Trade: What’s on the Horizon for Brands and Retailers, Traceability and Tariff Compliance Strategies for Brands and Retailers, Circularity and Fashion Innovation, and Industry Insights on Made in USA and the Global Outlook

Premiere Vision is strategically changing its approach to highlight French savoir-faire (know-how) at its main fashion industry trade shows, effective in 2026.

The organization is evolving its Made in France PV show by integrating its offerings into two major events: Première Vision Paris and Blossom Première Vision.

This move is part of Première Vision’s commitment to align with market changes, aiming to boost the clarity, coherence, and synergy of its events. The goal is to better serve brands, manufacturers, and regional businesses while showcasing French craftsmanship on a larger, more impactful national and international stage.

The integration will strategically reposition the ‘Made in France’ content. The event will feature a dedicated showcase and new curated content to elevate the visibility of French craftsmanship. This is intended to enrich the visitor experience and strengthen the connection between local production, creativity, and innovation.

The Blossom Première Vision show will now include premium garment manufacturers, creating new links between exceptional materials and high-end fashion production.

This new, consolidated format is designed to offer French companies significant advantages including increased visibility, access to a broader, more diverse visitor base, new synergies between various market segments

Florence Rousson, Chair of the Executive Board of Première Vision, commented that this evolution gives ‘new momentum’ to the Made in France initiative by strengthening its business, inspirational, and strategic dimensions. She stated that the decision reflects the company's ambition to put French know-how at the center of the Première Vision experience, building a platform that remains true to its DNA as a global hub for creative, sustainable, and competitive fashion.

From €6.44 billion in the prior year quarter, currency-neutral revenues of the brand adidas increased by 16 per cent to €6.63 billion in Q3, FY25.

The company’s gross margin edged up to 51.8 per cent during the quarter from 51.3 per cent in the corresponding quarter last year, overcoming headwinds from unfavorable currency shifts and higher tariffs. Its operating profit rose to €736 million compared to €598 million in 2024.

Based on this better-than-expected performance, adidas is significantly boosting its full-year guidance for 2025.

The company expects currency-neutral revenues for the core adidas to grow by double-digits during the year. However, including the prior-year Yeezy sales, total currency-neutral revenues are projected to increase by around 9 per cent, a slight improvement from the previous ‘high-single-digit rate’ forecast.

adidas’ operating profit for the full year is now expected to reach around €2.0 billion, as against the earlier projected guidance of between €1.7 billion and €1.8 billion. This improved outlook is credited to sustained brand momentum, the strong business execution, and successful efforts to offset increased US tariff costs.

Highlighting the company’s strong growth, Bjorn Guilden, CEO, expressed a positive outlook toward 2026, which is lined up to be a major sports year. adidas will release its full financial report on October 29.

A new analysis by Crisil Ratings indicates, the recent Goods and Services Tax (GST) changes will significantly impact India’s organized apparel retail sector this fiscal year. The tax rationalization is expected to add roughly 200 basis points (bps) to revenue growth, keeping the sector's expansion steady at 13–14 per cent for the second straight year. Crisil's study covered 40 organized apparel retailers, which account for nearly one-third of the sector's total revenue.

The government's GST revision created a dual effect. The uniform 5 per cent GST rate was extended to apparel priced up to Rs 2,500. This widening of the lab is set to spur demand in the price-sensitive fast-fashion and mid-premium categories, especially during the festive season.

Conversely, the GST rate on apparel priced above Rs 2,500 was increased from 12 per cent to 18 per cent. This hike impacts the premium category, which includes wedding wear, woolens, and embroidered clothing, and makes up about 35 per cent of organized sales.

Anuj Sethi, Senior Director, Crisil Ratings, notes, the timing of the rate cut - coinciding with the festive season - is expected to stimulate middle-class spending. This, combined with easing inflation and shorter fashion cycles, will give retailers a modest advantage in discretionary spending.

However, the higher GST on premium apparel could dampen demand, particularly for items priced in the Rs 2,500 to Rs 3,500 ($28 to $40) range, potentially causing some consumers to trade down. Poonam Upadhyay, Director, Crisil Ratings, suggests, retailers with a larger share of premium products may choose to absorb part of the GST hike to sustain festive and wedding season demand.

Retailers are expected to benefit from lower input costs, as the GST on cotton and synthetic fibers/yarn has been reduced to a uniform 5 per cent. Since raw materials constitute nearly two-thirds of production costs, the sector’s operating margin is projected to slightly improve from 14 per cent last year to 14 per cent–14.5 per cen this fiscal year.

Overall, the GST changes reflect shifting consumption patterns driven by a growing middle class and a preference for affordable, fashion-forward clothing, though any resurgence in inflation could pose a challenge.

When Beijing announced plans to enter the international carbon markets this October, the message was unmistakable: China no longer intends to simply follow global climate rules, it aims to write them. The move, revealed in the ‘Progress Report of China’s National Carbon Market (2025)’ by the Ministry of Ecology and Environment (MEE), signals a new chapter in both China’s domestic environmental policy and global climate strategy. The report states that China will “promote fulfillment of international carbon reduction commitments through cross-border carbon trading,” positioning the country not just as a manufacturing giant but as an emerging powerhouse in green finance and climate governance. This shift, while technical in language, reflects something far more ambitious, a recalibration of China’s economic engine for a carbon-constrained world.

Laying the domestic foundation

Before stepping onto the global carbon stage, China spent the past three years building a sturdy domestic foundation. Since 2024, the government has increased the construction of a multi-layered legal and institutional framework to ensure the carbon market’s credibility and continuity.

Two policy documents: ‘Opinions on Advancing Green and Low-Carbon Transition and Strengthening the Construction of the National Carbon Market’ and the ‘Interim Regulations for the Management of Carbon Emission Trading’ laid down the rules of engagement. They codified everything from data verification and emission caps to penalties for fraud and data falsification, addressing one of the main concerns voiced by international observers: transparency.

“China’s focus on data integrity and compliance demonstrates that this is not just a political statement but a serious economic restructuring,” says Li Zheng, Executive Vice President at the Institute of Climate Change and Sustainable Development, Tsinghua University. “It’s about building market credibility at home before competing abroad.”

Broadening the market

The expansion of the National Carbon Emission Trading System (ETS) marks the most dramatic development since its inception. Approved by the State Council, the inclusion of steel, cement, and aluminum smelting brings more than 1,300 new entities into the fold raising the total to nearly 3,500.

With this, China’s ETS coverage has rose:

• Regulated emissions: up from 5 billion tonnes to 8 billion tonnes of CO₂ equivalent

• Emission types: now include CF₄ and C₂F₆, potent industrial greenhouse gases

• National coverage: from 40 per cent to over 60 per cent of total emissions

The expansion, to be implemented in phases through 2026, maintains an intensity-based approach, allowing enterprises to grow while improving their carbon efficiency. This contrasts with the absolute cap model dominant in the EU, reflecting Beijing’s attempt to balance growth and green transition. “China’s approach is pragmatic,” notes energy economist Zhao Mei of the Chinese Academy of Social Sciences. “It recognizes industrial realities while pushing firms to innovate, not stagnate.”

A market gaining momentum

What began as a cautious experiment in 2021 has now evolved into one of the world’s most active carbon markets. By 2024, the national carbon market reached a record annual transaction value of 18.11 billion yuan, and as of August 2025, cumulative transactions had climbed to 47.83 billion yuan. Prices for China Carbon Emission Allowances (CEAs) breached the symbolic 100 yuan/tonne mark for the first time in April 2024, an indication of tightening demand and investor confidence.

Table: China market's performance

M

|

Metric |

2024 |

|

Annual cumulative trading volume |

189 million tonnes |

|

Annual transaction value |

18.11 billion yuan |

|

Year-end composite closing price |

97.49 yuan/tonne |

|

Number of participating entities |

1,471 |

|

2023 compliance rate |

99.98% |

The near-perfect compliance rate is impressive observers, particularly given the system’s size and diversity. Analysts credit this success to digital monitoring systems and blockchain-backed verification tools introduced under the new regulations.

The rise of the voluntary carbon market

Parallel to the ETS, China launched its National Voluntary Greenhouse Gas Emission Reduction Trading Market in January 2024, signaling a whole-of-society approach to decarbonization. This platform allows companies, investors, and even local governments to offset emissions by funding certified green projects.

Among its early success stories is the Dongtai Offshore Wind Project by China Energy Investment Corporation in Jiangsu. The project, approved for 857,000 tonnes of CO₂-equivalent credits, has generated nearly 70 million yuan in trading revenue, translating to an extra 0.039 yuan per kilowatt-hour of electricity produced. By August 2025, the voluntary market recorded:

Cumulative trading volume: 2.71 million tonnes

• Turnover: 229 million yuan

• Active projects: 106 (spanning wind, solar, and afforestation)

“This market is more than symbolic,” explains Xu Han, Director of Green Finance at the Shanghai Environment and Energy Exchange. “It’s about turning ecological value into financial capital, a pathway for innovation and job creation.”

Global ambitions of cross-border carbon trading

China’s entry into international carbon markets marks a geopolitical inflection point. The MEE’s report confirms that Beijing is actively formulating administrative measures for cross-border carbon trading, a move that could redefine the architecture of global carbon governance.

This effort aligns with President Xi Jinping’s vision of a “community with a shared future for mankind,” extending China’s domestic carbon successes into an instrument of international cooperation. Beijing aims not only to meet its own 2060 carbon neutrality target but also to help developing nations achieve their decarbonization goals through technology and market access.

Already, China is exploring bilateral carbon trading frameworks with ASEAN countries, Africa, and the Middle East regions with abundant renewable potential but limited carbon finance infrastructure. “China’s entry into global carbon markets could create a counterweight to the EU’s Carbon Border Adjustment Mechanism (CBAM),” says Jonathan Watts, Asia Climate Editor at The Guardian. “It’s about influence economic, environmental, and geopolitical.”

Yet the path forward isn’t without hurdles. Questions remain about the comparability of China’s carbon credits with international standards like those under the EU ETS or the Article 6 mechanisms of the Paris Agreement. Market analysts caution that without harmonized verification and transparency standards, integration may remain limited.

Also, industries under pressure particularly heavy manufacturing face rising costs as compliance tightens. Still, many experts see opportunity in adversity. “The carbon market is forcing Chinese industries to digitize, optimize, and innovate faster than ever,” says Li Zheng. “It’s a new competitiveness metric for the 21st century.”

Carbon as currency

For China, carbon trading has evolved beyond environmental policy it is now an economic instrument, a diplomatic lever, and a signal of its ambitions in the global sustainability economy. By increasing its carbon markets, strengthening data integrity, and embracing international cooperation, Beijing is crafting a vision of climate capitalism with Chinese characteristics. Whether the world follows its lead remains to be seen but one thing is clear: China is no longer content to be a participant in global climate governance. It is positioning itself to be its architect.

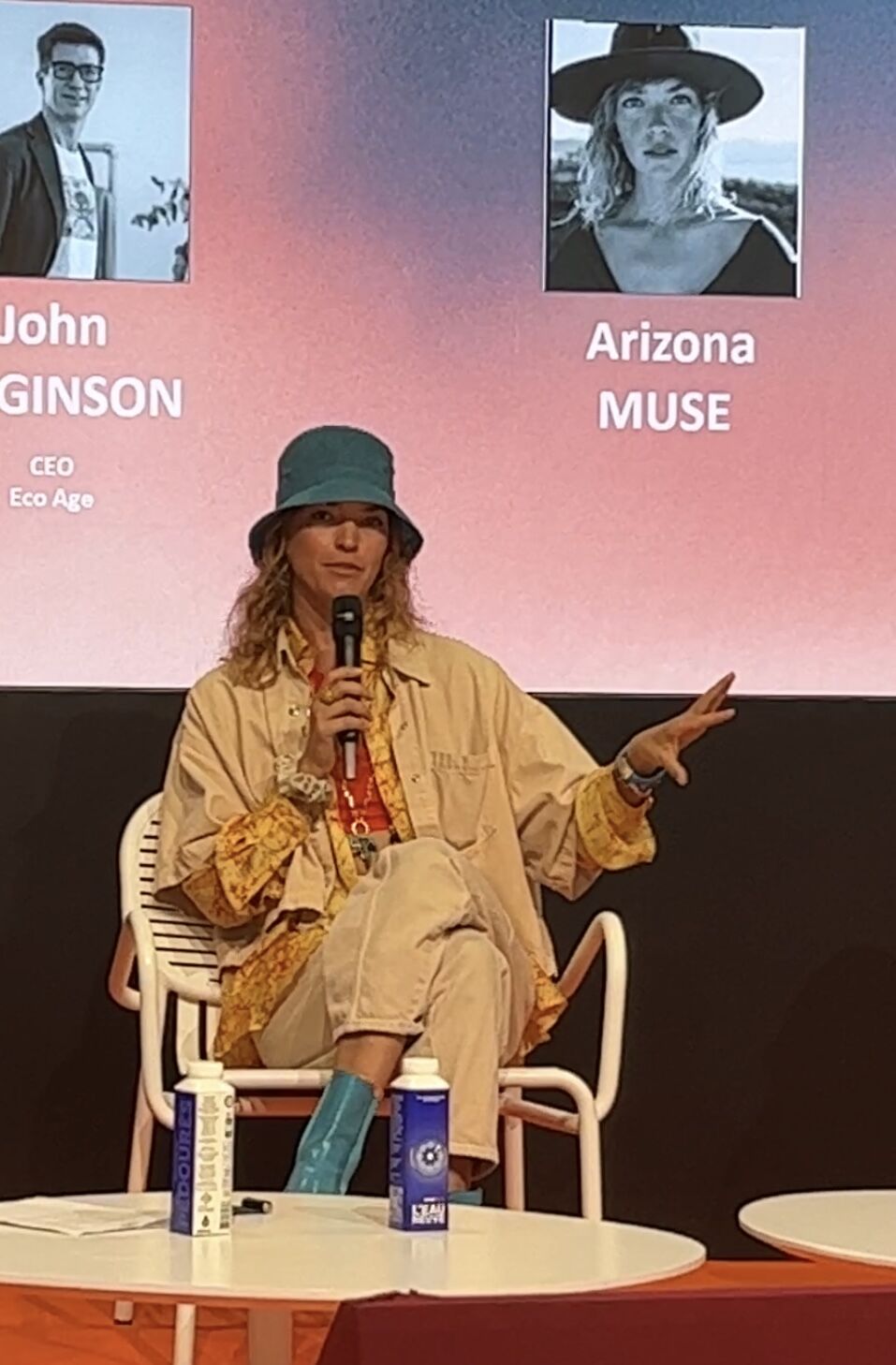

“We need to make fashion for worms. Fashion that can decompose in the soil.” When Arizona Muse, model and environmental activist, delivered this provocative line at Première Vision Paris, she wasn’t being poetic. She was crystallizing fashion’s most pressing contradiction, an industry that dreams of sustainability but remains shackled to the economics of convenience.

In 2025, the global fashion sector finds itself in a peculiar state of duality. On one hand, it’s bursting with innovation bioplastics, enzymatic recycling, regenerative materials. On the other, it’s suffocating under its own addiction to cheap polyester and fast cycles of consumption. The tension between progress and affordability has never been starker.

The polyester paradox

At the heart of the debate lies polyester, the fossil-fuel-based fiber that has come to define modern clothing. It is cheap, durable, and adaptable and it accounts for more than half of all fibers used in apparel today. Yet, as Arnaud Brunois-Gavard, Sustainability Manager at ECOPEL | Faux Fur Artisan, admits, breaking free from polyester is no easy feat. His company’s latest innovation, Biofur, a plant-based faux fur made from fermented corn sugar (PLA) embodies the future of circular fashion. But demand tells a different story.

“Despite the new material we offer, the client orders our polyester products,” he laments. It’s not a lack of innovation holding the industry back its economics. Polyester remains far cheaper than its eco-friendly counterparts, and with cotton prices surging due to erratic harvests, the dominance of synthetics is only deepening.

The new frontier, enzymatic recycling

Yet, innovation persists. On the trade fair floor in Paris, amid rows of recycled textiles and organic yarns, one breakthrough stood out: enzymatic recycling. Unlike mechanical or chemical recycling, which degrade material quality, enzymatic recycling breaks down polyester to its molecular core allowing it to be reconstituted into virgin-quality fiber. “This enables infinite recycling of polyester,” explains Greta Edkvist, Brand Manager at Chinese company Reo-Eco. “In theory, it can eliminate the need for new raw materials altogether.” If scaled successfully, enzymatic recycling could make synthetic fibers circular transforming plastic fashion into a resource loop rather than a waste stream. But in theory is doing heavy lifting.

Infrastructure, the missing link

The grand promise of a circular economy falters without one critical component collection and sorting infrastructure. Across much of Europe and Asia, textile waste systems are disjointed, underfunded, or nonexistent. Moreover, ultra-fast fashion has worsened the problem. The flood of cheap, blended fabrics produced by global giants makes recycling nearly impossible. The materials are too low in quality and too complex in composition for most recycling technologies to process. “You can’t close the loop if what’s inside it keeps breaking,” says a sustainability analyst at the event. This broken loop is emblematic of fashion’s circular challenge a system built for speed and scale now struggling to retrofit sustainability onto a model designed for disposability.

The consumer conundrum

And then there’s the consumer, the final, decisive link in the chain. A recycled wool fleece priced at €300 competes with a polyester version sold for €30. For most, the decision isn’t moral; it’s mathematical. “People talk about sustainability, but their wallets still vote for convenience,” opines an European retailer notes. This green hypocrisy, consumers advocating eco-consciousness while shopping for the cheapest option, results in the paradox. Sustainability cannot thrive on rhetoric alone. As one industry observer put it, “We need consumers who not only talk about green fashion but buy it. Otherwise, innovation will remain a showcase, not a solution.”

From greenwashing to ground truth

The industry’s shift toward circularity also demands honesty from both brands and buyers. Greenwashing has diluted public trust, as labels tout eco-friendly collections that merely offset, rather than overhaul, unsustainable practices. True change, experts say, will require transparency from brands and patience from consumers. Circular materials and enzymatic recycling can make fashion renewable but only if the market rewards such efforts.

Fashion for worms and humans

Arizona Muse’s phrase ‘fashion for worms’ isn’t just a metaphor. It’s a manifesto for transformation. To make biodegradable fashion mainstream, every link in the supply chain must evolve: from innovators creating compostable fabrics to governments investing in textile recycling, and consumers choosing products that outlast trends rather than landfill lifespans.

Fashion’s next revolution won’t be defined by color palettes or hemlines but by chemistry, ethics, and economics. The path to ‘fashion for worms’, might just begin when the industry and customers decide that the price of progress is worth paying.

Retail sales in the UK increased by 2.3 per cent Y-o-Y in September 2025, as per a joint report by the British Retail Consortium (BRC) and KPMG.

As per the report, this growth rate was slower than the 3.1 per cent recorded in August, indicating a cooling of consumer spending as households exercised greater caution.

The growth in the value of sales was often due to higher prices (inflation) rather than an increase in the volume of goods purchased. Data from Barclays also shows, overall consumer card spending actually declined by 0.7 per cent Y-o-Y in September.

Non-food sales increased by a meager 0.7 per cent Y-o-Y during the month, which was well below the 12-month average.

This cautious consumer behavior was linked to a mix of economic and seasonal factors including the looming Autumn Budget (scheduled for November) and fears of potential tax increases that weighed heavily on consumers' minds as they plann their budgets, especially for Christmas spending.

Unseasonably mild temperatures across the UK led shoppers to delay purchases of autumn and winter clothing and footwear, directly impacting the non-food sector. Consumers also remain highly selective, prioritizing ‘pick-me-up’ purchases in categories like furniture, clothing, and beauty, while making broader cutbacks in essential spending, which declined by 2.6 per cent Y-o-Y according to Barclays.

The data suggests that while the retail sector is still showing growth in monetary terms, the underlying spending behavior is becoming increasingly cautious and targeted due to persistent inflationary pressures and economic uncertainty.

A growing number of British high-street fashion brands, including River Island and New Look, have been closing physical stores throughout 2025, with more potential closures on the horizon.

This trend suggests that the struggle for brick-and-mortar retail isn't limited to discount stores (like Poundland) or coffee chains (like Costa Coffee), but is now significantly impacting the fashion sector.

This year has proved to be a severe low point for retailers overall. Several factors like rising operational costs and dwindling sales are forcing many established brands to consider shutting down stores.

The industry downturn has had direct consequences for employees, as retail employment has experienced a notable slump compared to previous years.

While the approaching holiday shopping season typically brings a boost in sales and the hiring of temporary staff to manage the Christmas rush, the overall trajectory for UK physical stores suggests a grim long-term picture for the future of traditional shopping.

French apparel brand Damart is aggressively pursuing international expansion and a breakthrough into mass-market retail by 2026. Known for its proprietary fabrics like Thermolactyl and Evolutyl, the brand is focusing its growth efforts on Europe and digital channels.

Damart is prioritizing e-commerce to expand its reach. Already a top-selling fashion name on French platforms like Veepee, the brand is strategically approaching international e-tailers. Its recent launch on German platform Zalando necessitated a supply chain upgrade to offer a four-day delivery window, a benefit now extended to all its online customers. The brand is focused on countries neighboring France, with plans to enter Austria in early 2026. This e-tailer strategy allows Damart to efficiently identify key markets before launching its dedicated local e-shops.

This digital focus is paying off: one-third of Damart’s e-tail sales are now generated outside of France, a figure expected to reach 50 per cent next year. Online business currently accounts for 21 per cent of total revenue.

Damart is also evolving its physical presence and products. For the first time ever in 2025, Damart’s store sales surpassed its traditional catalogue (mail-order) sales, emphasizing the importance of the in-store experience.

The brand plans to enter an undisclosed mass-market chain in Fall/Winter 2026, offering its signature t-shirts at a promotional price of €19.90 (down from €24.90).

Damart is developing innovative recycling solutions, including comforters made from 70 per cent recycled fabric offcuts and shoes using re-spun fibers.

It's combining its popular thermal Thermolactyl with the waterproof RainProtect range for colder seasons and boosting the use of its temperature-regulating Evolutyl fabric.

To kick off its key selling season, Damart will launch an extensive multi-media campaign from October 17 to November 30 across major TV and streaming platforms like Netflix, Prime Video, and Disney+. This push follows a stable performance by its parent company, Damartex group, which recorded a revenue of €521 million in the last fiscal year.

The Textile Institute (TI) plans to grow its global network by welcoming new Corporate Members at the upcoming ITMA Asia + CITME textile machinery exhibition in Singapore later this month

As the only global professional body in this sector with a Royal Charter, TI drives the industry forward through high-quality events and training courses that prepare professionals for the future, says Stephanie Dick, CEO. Together with its Corporate Members, the institute addresses skills gaps and develops practical training solutions to reach international audiences, she adds.

A Corporate Membership of the Institute provides a variety of advantages, including global promotion and visibility, invitations to high-level networking events and training, collaboration on industry-led research, professional recognition through chartered qualifications, and access to TI’s publications, data, and R&D resources.

TI offers a neutral, not-for-profit platform where a members’ voices are heard and their goals are supported, adds Charles Wood, President.

The Textile Institute is ideally positioned to help organizations stay competitive, connected, and compliant. Since its founding in Manchester in 1910, its mission has always been to be ‘not of Manchester, but international. With sections and special interest groups active worldwide, it now serves members in over 60 countries, empowering professionals across every part of the textile supply chain.