FW

Shanghai Tex will be held in China from November 27 to 30, 2017. It will focus on sports knitting technologies that create high performance sportswear for sports lovers.

The sports arena will look into three hot topics: sports bra, wearable technology and shoe technology. 3D printing innovator Materialise will display 3D printing technology. Sports Arena will attract professionals from different fields such as shoe uppers, soles, 3D printing and smart technology to explore the latest sports shoes developments and trends. Issues of comfort, support, shoulder strap design and function remain the main challenges in sports bra production. Exports on the intimate apparel industry will address both theoretical and practical matters in various bra issues.

Shanghai Tex will be held in China from November 27 to 30, 2017. It will focus on sports knitting technologies that create high performance sportswear for sports lovers.

The sports arena will look into three hot topics: sports bra, wearable technology and shoe technology. 3D printing innovator Materialise will display 3D printing technology. Sports Arena will attract professionals from different fields such as shoe uppers, soles, 3D printing and smart technology to explore the latest sports shoes developments and trends. Issues of comfort, support, shoulder strap design and function remain the main challenges in sports bra production. Exports on the intimate apparel industry will address both theoretical and practical matters in various bra issues.

By 2020 China is projected to become the second largest R&D industry globally, overtaking Japan. From 2016 to 2020 China planned to increase R&D expenditure’s share of GDP to 2.5 per cent by 2020. The country aims to become a high-tech regional hub encouraging scientific innovations and their commercialisation under the Scientific Innovation 2030 initiative and industrial transitioning plan – Made in China 2025.

The latter initiative is set to fuel innovation in manufacturing industries and support the development of emerging industries such as IT, 5G mobile communications, computerised machines, robotics, electric vehicles, medical devices, artificial intelligence, and bio-pharmacy.

However, industry’s development is projected to be negatively affected by growing skills shortage in the country, with graduates in science recording the lowest increase in number during 2011-2016. One of the most interesting yet least appreciated facets of modern China is its transformation from a low-cost, labor intensive manufacturer to an economy driven by an indigenous, self-sustaining process of technological change. The emergence of home grown research and development culture in China will not only help the country transition from developing to developed country status but also boost its transformation from an export to a consumption-led economy.

For the West, the rise of innovation and R&D in China means that the next big wave of Chinese competition is only a few years away – this time from China’s innovation prowess, not just its cheaper labor.

Cambodia’s garment and footwear industry generated over $6.5 billion last year while providing jobs for about 7,00,000 workers. Improving workers’ wages, health care, transport and working environment is likely to benefit employers by resulting in increased worker efficiency.

Improving labor productivity would be fundamental for Cambodia to remain competitive, given rising competition from other low-wage garment exporting countries. Cambodia wants preferential trade terms for its footwear exports from the United States.

Preference systems let developing countries export certain goods to donor countries at reduced tariff levels. Cambodian footwear, textiles and garments are excluded from the US GSP. Cambodia’s footwear and garment industry exports under the US’ most favored nation program are taxed by the US, which wants to protect its local industries. Cambodia’s real growth is projected to remain strong, expanding at 6.9 per cent in 2017 and 2018.

Risks to this outlook include the fallout from further rises in US interest rates, a slower-than expected economic recovery in Europe, and uncertainties over global trade. US monetary policy tightening is expected to result in the dollar appreciating vis-a-vis the euro and other currencies, which would make Cambodia’s exports and tourism relatively more expensive for the rest of the world, and therefore less competitive.

The African Development Bank (AfDB) aims to support the growth of the African textile and fashion sectors through focus on building capacities of micro, small and medium-sized enterprises, especially for women and youth. AfDB has taken the lead in promoting investments in the textile and fashion sector, increasing access to finance for entrepreneurs and incubating and accelerating start-ups.

In addition to using its traditional public- and private-sector financing instruments to support the growth of the textile and fashion industry, AfDB is developing innovative and technology-driven Fashionomics Africa platform, an online interactive marketplace for medium and small scale enterprises and relevant stakeholders in the textile and fashion sectors in Africa. The goal is to enable young African textile and fashion entrepreneurs to create and grow their businesses.

AfDB feels Africa should be exporting finished textile products, such as clothes, suits, dresses, shirts, and not cotton lint. Africa produces up to six per cent of the world’s cotton, but the continent has very few textile factories and, due to poor industrialization, much of the fabric is imported from Asia.

However, the growth prospect of fashion industry in Africa is promising. Steps in this direction are fostering the development of local suppliers, entrepreneurs, and regional value chains, ensuring access to low-cost financing, building a more conducive business climate, buying from locally owned companies, investing in infrastructure and establishing more educational institutions.

"With China’s labour cost increasing, the country is shifting focus on automation to make factories more efficient. For instance, Chenfeng Group, a leading contractor for Uniqlo operated by Japan's Fast Retailing, recently set up a production line using a hanger system in a corner of its huge garment factory in Changzhou, Northwest, Shanghai. The factory makes 1.3 million shirts a month. This new system allows shirts to be assembled on a single hanger that moves around the production line, guided by circular rail suspended from the ceiling. The hanger stops in front of a worker, who attaches a part to the shirt or performs a task. "

With China’s labour cost increasing, the country is shifting focus on automation to make factories more efficient. For instance, Chenfeng Group, a leading contractor for Uniqlo operated by Japan's Fast Retailing, recently set up a production line using a hanger system in a corner of its huge garment factory in Changzhou, Northwest, Shanghai. The factory makes 1.3 million shirts a month. This new system allows shirts to be assembled on a single hanger that moves around the production line, guided by circular rail suspended from the ceiling. The hanger stops in front of a worker, who attaches a part to the shirt or performs a task. When the worker is done, the hanger moves on to the next step, making its way around the circle until the item is finished.

Technology to boost production

There are around 50 sewing machines and their operators are deployed along the rail. Sensors determine how fast each operator is working and send the shirts to the best operator for the task at hand. The time needed to complete each step varies, depends on its complexity and the skill and experience of the worker. As one of the factory officials informed, before the new assembly method, it was difficult to keep track of progress for each of the 47 steps in the assembly process. Delays in particular steps slowed production all along the line. The new system raises production efficiency by 15 per cent.

Looking at the gains, the company is eyeing to introduce the system at around 200 of its production lines in its nine factories across China in the next two years. This will increase total output to 10 million shirts monthly by 2020, from roughly 6 million at present. Chenfeng plans to spend a total 2 billion yuan ($299 million) from fiscal 2013 through fiscal 2018 to increase production.

The change is just not limited to the hanger system but also to automating specific processes. The company is working on semi-automation of tasks such as attaching buttons and pockets, as well as sewing the center back line. This would drastically reduce the number of people needed for each step from several operators to just one. CEO Gao Dekang point out, the company is considering moving some production to Vietnam and other locations abroad. At present, about 20 per cent of its production lines are automated. The company wants to increase the percentage to 50-60 per cent within several years. Potential areas for automation include fabric cutting machines and down filling machines. The company is also looking to introduce robots for picking goods in warehouses and shipping.

Rising labour cost – a concern

According to the Japan External Trade Organization, the monthly basic wage in China topped $400 on average last year. That was twice as high as the monthly wage in Vietnam, and four times higher that of Bangladesh. Labour costs in China are expected to continue rising 10 per cent a year or more. That has already prompted some garment makers to shift production to Southeast Asia. In 2015, China's clothing exports totalled $175 billion, or around 40 per cent of global exports, according to data from the World Trade Organization. The value fell 6 per cent from a year earlier, while shipments from emerging economies such as Bangladesh, Cambodia and Vietnam increased.

For its 93rd edition, Pitti Uomo, the menswear tradeshow, which opens on January 9 and runs till January 12 in Florence, Italy, has announced 'film' as this year's theme and another roster of newcomers and big events which are expected to transform the show's venue Fortezza da Bassa ‘into a prestigious global platform, chosen by brands for the international unveiling of new trends and unpublished projects,’.

Showcasing latest in men's autumn/winter 2018-19 collections, the upcoming show will bring together 1,230. Among these, 541 will be international (some 44 per cent of the total) and 227 will be either making their debut or be returning after a break. One such case is that of Corneliani, which quit Pitti seven years ago, opting instead to showcase in Milan. Joining this season is Gazzarini, who for a long time has showcased in Milan and returns with a special presentation-cum-party on the opening day. Also returning to the show is Paul & Shark, Fratelli Rossetti and Pepe Jeans London, which will celebrate its 45th anniversary during the week. So also will Dutch jeans brand Denham, set to commemorate its tenth birthday at the Florence show.

American menswear label Brooks Brothers has chosen Pitti to celebrate its milestone, its bicentenary, on, January 10 in the grand Salone dei Cinquecento de Palazzo Vecchio (the historic palace of the Florence city hall). The program includes a first-ever runway show by Brooks Brothers and an exhibition on the brand.

Karl Lagerfeld is another headliner to watch, and will show a preview presentation of his new menswear project. Of interest are the show's guests of honour for this edition: Jun Takahashi from the brand Undercover and designer Takahiro Miyashita, who heads up Takahiromiyashita The Soloist. Other highlights include Italian brand Malibu 1992, which has been renamed M1992 and the first-ever runway show from Luca Magliano, the winner of design competition Who’s On Next Uomo 2017, with his namesake label Magliano.

Korean designers Beyond Closet and Bmuet(te) are also set to star, alongside new Japanese talent Body Song, Children of the Discordance, Digawel, F/CE, Kuon and Soe. Other headline events include the announcement of the Woolmark prize men's and women's winners and the opening of a new space featuring designs from Finland. There will also be a number of parallel events taking place in the city with the opening of new stores by Moncler and Ermanno Scervino and the Gucci Garden which will double as both store and restaurant for the luxury brand.

The Taiwan New Products Launch, hosted by The Taiwan External Trade Development Council (TAITRA), at the outdoor retailer summer market in Salt Lake City, saw four of Taiwan’s leading textile manufacturers ‘Far Eastern New Century, QMI Industrial ‘Singtex Industrial and Tex-Ray Industrial showcase their innovative products.

Speakers spoke of the vision for Taiwan’s textile industry. And Simon Lai, Executive Director, Taiwan Trade Center, San Francisco pointed out they introduced breakthrough products and materials that represent the best of Taiwanese textile innovation.

With growing trend towards eco-friendliness, Taiwanese suppliers have focused their R&D on green technologies to meet demand and achieve goals of sustainability and corporate social responsibility pointed out Joseph C.L. Ma, Director-General, Taipei Economic and Cultural Office, San Francisco.

Taiwan’s leading textile manufacturers presented innovative products, under various product categories including cutting-edge fabric printing technology; smart textiles measuring heart rate and motion data; textile innovations utilizing fewer chemicals, water and raw materials while preserving function and complex colors; and the world’s first PFC-free durable water repellant (DWR) polyester filament, PFC-free soil release polyester filament, and bio-based membrane and foam from coffee oil. It maybe noted that Taiwan is one of the world’s largest functional fabric production base.

Cotton output is expected to increase 4 per cent to 34.5 million bales (of 170 kg each) in the cotton year ending September on the back of sharp rise in yield. However, the acreage under cotton has dropped 11 per cent to 10.84 million hectares (12.29 million hectares). The yield per hectare is expected to increase to 541 kg from 459 kg.

Kavita Gupta, Textile Commissioner and Chairperson of CAB, says cotton export is expected to decline to 6 million bales this year from 6.9 million bales last year with concern over availability of cotton in domestic markets. Exports to Pakistan have fallen drastically while Bangladesh accounted for 40 per cent of total exports from India till May.

Better crop management and efficient protection mechanism would reduce the impact on the productivity in the coming season. The area under cotton crop is expected to bounce back to 11.9 million hectares the next season and the output is set to grow in double digits. Data compiled by the Ministry of Agriculture till mid-August show 18 per cent increase in cotton acreage for the crop year 2017-18 (October–September).

The use of home-grown cotton variety developed by the Central Institute for Cotton Research, Nagpur, has increased this year, Gupta added. She further stated that the Indian Council of Agricultural Research has also come up with more native varieties, which are good in yield. Once they are commercialised in 2017-18, the area under the indigenous variety will increase further.

Chinese fashion designers have continued to make strides on international stage in 2017. During the upcoming Spring/Summer 2018 Fashion Week in Milan, Paris, London and New York. 30 designers who are either Chinese or have a connection to China will debut with their latest collections at one of the major shows.

In February 2017, shows in Milan, Paris, London, and New York for Fall/Winter saw 26 Chinese designers presenting shows around the world demonstrating that the global fashion world has become increasingly receptive to Chinese designers and recognizes their significance to the industry. New York has once again attracted the highest number of talent from China, with 16 designers and their brands participating this September.

The New York-based Hong Kong designer Vivienne Tam is another big name who has consistently attended New York Fashion Week. In an interview with Jing Daily earlier this year, Tam told us that New York was quite a special place for her as it was where she gained her early fame. She will host most of her fashion shows in the city in the near future.

Iconic American designer Anna Sui, who had a career retrospective open at London’s Fashion & Textile Museum in May, has been a mainstay at New York Fashion Week since her first runway show there in 1991. Though she was born in Detroit, Michigan, she makes this list because of her Chinese heritage.

Chinese fashion designers Angel Chen and Ricostru, sponsored by National Chamber of Italian Fashion, will attend Milan Fashion Week. The brand Tommy Zhong, established by two emerging fashion talents Zhong Jiaqi and Jenny Nelson, will also debut its collection in Milan.

"CMAI’s Q1 Apparel Index for April-June FY 2017-18 reflects positivity is in the air. At 2.77 the index value for the quarter has moved up compared to previous quarter, Q4 (Jan-March FY 2016-17) when it was 2.25 points. The market recovered after ‘demonitisation’. However, the industry faced yet another tight spot in the form of GST in June. And most players paused deliveries, as buyers were uncertain about post GST inventory implications. They focused more on clearing inventories before buying fresh goods."

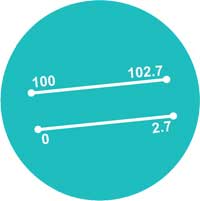

CMAI’s Q1 Apparel Index for April-June FY 2017-18 reflects positivity is in the air. At 2.77 the index value for the quarter has moved up compared to previous quarter, Q4 (Jan-March FY 2016-17) when it was 2.25 points. The market recovered after ‘demonitisation’. However, the industry faced yet another tight spot in the form of GST in June. And most players paused deliveries, as buyers were uncertain about post GST inventory implications. They focused more on clearing inventories before buying fresh goods.

Giant Brands’ perform best, record highest index value

Meanwhile some players took this opportunity to clear inventory, especially big retailers and brands associated with them. This is evident in the apparel index of various brand groups. Giant Brands, mostly the ones with widest retail network clocked in 11.00 points, followed by Large Brands at 4.25 and Mid Brands 3.71 points; Small Brands with least retail control mostly dependent on trade recorded lowest apparel index of just 1.47 points.

Giant Brands also took this opportunity to facilitate recovery with a fabulous 11.00 points growth, with fast clearance of goods that increased Sales Turnover to 7.40 points. Comparatively, Large Brands sales turnover grew 2.00 points and Mid Brands sales turnover grew 2.30, Small Brands, the laggards, clocked in a mere 1.00 points this quarter. Overall the Index Value this quarter saw more impact and dynamism from sales turnover. Moreover inventory holding was much less compared to earlier quarters as the emphasis was on liquidation rather than inventory building.

Q1 Apparel Index clearly indicates Giant Brands have outdone Large, Mid and Small Brands. Small, Mid and Large Brands could manage small growth in sales turnover, perhaps due to stalled or reduced deliveries during the month of June. Giant Brands being connected with organized retail through MBOs, EBOs and large format stores managed their business and sales turnover well. Moreover, they took the discounting route which stimulated sales to clear off inventory at store and company level. This is clearly reflected in their increased sales turnover which was 7.40 points.

High sales turnover, low inventory holding works best

There is a strong correlation between sales turnover and inventory holding, and this is clearly evident this quarter. Organized companies and brands understand boosting sales leads to lower inventory holding, relieving cash for the company which boosts fund circulation. Since Small and Mid Brands are more dependent on trade and have less control on retail, they are not in a strong position to push up sales. At the same time, Large and Giant Brands are using this tool successfully to stimulate sales turnover, thereby restricting inventory holding.

As Sanjay K Jain, Managing Director, TT Ltd points out, “We managed to reduce inventory by using MIS and forecasting tools effectively. Instead of monthly monitoring, we shifted to weekly monitoring of sales trends.” Agreeing with this point of view Kapil Gupta, Director, Toppler goes on to add, “We focused on increasing sales and decreasing inventory holding. Inventory holding was low because we produced only those goods which were pre sold. We also stopped purchasing new fabrics and focused on clearing our stock. This helped us liquidate our fabric stock, and reduce inventory holding.”

Positive outlook for next quarter

With festivals and weddings lined up in the upcoming quarter there is a sense of positivity about business, around 55 per cent brands feel the outlook for next quarter is ‘Good’, another 10 per cent say the outlook is ‘Excellent’. Nearly 33 per cent foresee an average outlook and 2 per cent feel it will be ‘Below Average’. Generally, Q2 of the financial year 2017-18, is seen as the best quarter as most festivities fall during this period, brands expect a good season, coupled with almost dry supply chain and shelves in quest of fresh goods. Consumers too are expected to return to stores, GST and new processes would be settled especially by beginning/mid August and this augurs well for business.

CMAl's Apparel Index aims to set a benchmark for the entire domestic apparel industry and help brands in taking informed business decisions. For investors, industry players, stakeholders and policymakers the index is a useful tool offering concrete and credible information, and is an excellent source for assessing the performance of the industry. The Index is analysed by assessing the performance on four parameters: Sales Turnover, Sell Through (percentage of fresh stocks sold), number of days of Inventory Holding and Investments (signifying future confidence) in brand development and brand building. The Apparel Index research is conducted by DFU Publications.