FW

As the Intertextile Shanghai Apparel Fabrics - Autumn Edition drew to a close, Olaf Schmidt, Vice President of Textiles & Textile Technologies at Messe Frankfurt, addressed the media, highlighting the role of exhibitions as a crucial platform for the textile industry to navigate global trade uncertainties, particularly those stemming from tariffs and geopolitical shifts.

Exhibitions as a counter-strategy to uncertainty

Responding to questions about the impact of tariffs on exhibitor and buyer numbers, Schmidt acknowledged the widespread concern. Echoing a sentiment raised by the media, he emphasized that the exhibition's dynamic nature and its ability to connect global players offer a powerful counter-strategy.

Resilience and optimism drive the industry

Schmidt's perspective, however, was one of resilience and optimism. He noted that the discussion about tariffs is not a new topic, and companies have been forced to adapt for months. "Every morning you can look on the phone, something is changing and companies have to survive and say, 'okay, how can we do this and what should we do?'" he said.

He stressed that companies are embracing a proactive approach. "My discussion with many companies at our shows is that they say, 'okay, we have to be optimistic, we have to look for new markets, new opportunities.'" This is precisely where exhibitions prove their value. "I think an exhibition is exactly the right platform to generate new business," he affirmed.

Global platform for diversification

Schmidt also highlighted the strategic diversification of supply chains, a trend that began during the COVID-19 pandemic and is now being accelerated by trade tensions. He pointed to the growing presence of new participating countries, such as Ireland, the Netherlands, and Australia, underscoring the truly global nature of the platform.

"You can see this is really a global platform to make everybody see the new opportunities and try to find a solution," he stated. He added that Chinese companies are actively seeking to "make their production and their exports more, how to say, flexible and consistent," and are finding these solutions at trade shows.

Messe Frankfurt, a leading trade fair organizer, has seen its exhibitions become a crucial hub for the global textile industry as manufacturers and buyers grapple with the complexities of international trade and tariffs. Schmidt's message was clear: while trade tensions create challenges, they also drive innovation and a search for new opportunities. Exhibitions like Intertextile Shanghai Apparel Fabrics provide a vital space for the industry to come together, adapt, and build new, resilient business relationships.

A major apparel and footwear company, VF Corporation has sold its brand Dickies to a brand management firm, Bluestar Alliance for $600 million.

An iconic American brand known for its durable workwear, Dickies has been a cultural staple for over a century, popular in both workwear and streetwear circles. It's sold in 55 countries and is recognized for blending utility with style.

Bracken Darrell, CEO, VF Corporation, opines, the sale will help the company reduce its debt and improve its growth.

Joseph Gabbay, CEO, Bluestar Alliance, states, his company is committed to supporting its growth and unlocking its full value.

The deal is expected to be finalized by the end of 2025, pending the usual closing conditions and regulatory approvals.

The global digital textile printing market is projected to grow at 4 per cent CAGR from 2025-35 to reach a value of $5.6 billion by 2035.

As per a report by Future Markets Insights. this growth is likely to be fueled by the demand for faster production, customization, and sustainable practices that use less water and energy than traditional printing.

Consumers' preference for personalized and fashionable clothing is a major driver, with apparel accounting for over 38 per cent of the market. Brands are increasingly adopting this technology to enable just-in-time manufacturing and meet the demands of e-commerce.

Key technological advancements in print heads, inks, and software are improving quality and efficiency. Pigment-based inks are leading the way due to their versatility and eco-friendly nature, while polyester substrates remain the top choice for high-quality prints, particularly in sportswear and home textiles.

The market is growing steadily across the globe, with distinct regional drivers. The US market is projected to grow at a 3.8 per cent CAGR, thanks to the popularity of custom home décor. China, as the world's largest textile manufacturer, is set for a 5.4 per cent CAGR, while India is expected to see a 6.3 per cent CAGR, driven by its expanding apparel market and consumer spending.

The industry is made up of a tiered system of players. Tier I companies like Seiko Epson and Kornit Digital dominate with high production capacity and global reach. Tier II players such as Roland DGA focus on specific regions, and Tier III consists of smaller, local businesses that serve niche markets.

Major companies are investing in innovation to stay ahead. Recent developments include Roland DG's new eco-solvent inkjet printer, Seiko Epson's acquisition of Fiery, and ColorJet India's new high-volume printer.

With consumer demand for customization and sustainability continuing to rise, the digital textile printing market is poised for sustained growth. The focus on eco-friendly practices and technological innovation will redefine industry standards for quality and efficiency.

India has a strong domestic presence, making it’s the world’s biggest textile market with 1.4 million consumers, said Pabitra Margherita, Union Minister of State for External Affairs and Textiles at a convocation ceremony at National Institute of Fashion Technology (NIFT) in Bhopal. He made this statement amid concerns over steep tariffs imposed by the US on Indian textile products.

While the country consumes a large quantity of its own products, the government is now focusing on promoting ‘swadeshi,’ or locally made goods, he noted.

India has been a leader in textiles for centuries and continues to progress under Prime Minister Narendra Modi. It is a top exporter of apparel and other textile products, with 19 National Institute of Fashion Technology (NIFT) campuses playing a crucial role, he highlighted.

NIFT provides specialized courses and training to students who are expected to contribute to the textile industry's future, Margherita stated. These students are being encouraged to support local products first and help them gain a global presence, he added.

The popular retailer from Ireland, Primark is celebrating its 10th anniversary in the United States with plans for more growth.

A year ago, the company announced its first flagship store in Manhattan, located in Herald Square across from Penn Station. Primark recently also opened a new office in downtown Boston.

Kevin Tulip, President-US, Primark, says the company has been ‘very deliberate’ in its approach to the American market over the past decade. To introduce itself to American shoppers, last year Primark launched its first US brand campaign year called ‘That's So Primark.’ According to Michelle McEttrick, Global Chief Customer Officer, the brand aims to show budget-conscious consumers that they don't have to ‘sacrifice style.’

Founded in 1969, Primark's original mission was to provide affordable choices for everyone.\ The retailer also has a ‘Primark Cares’ strategy with several goals by 2030, including using only recycled or sustainably sourced materials for all its clothing, cutting carbon emissions in half, and working toward a living wage for its supply chain workers.

A denim manufacturer based in Pakistan, Artistic Milliners has acquired a majority stake in the iconic American denim company, Cone Denim from its parent company, Elevate Textiles.

The new combined entity will operate globally under the Cone Denim brand name, while Artistic Milliners' operations in Pakistan will continue to function independently. This acquisition is seen as a way to create a global powerhouse in the denim industry, combining Cone Denim's long-standing heritage with Artistic Milliners' innovation and global manufacturing network.

Steve Maggard, President, Cone Denim, will lead the new entity. The deal is expected to be finalized in Q1, FY26. This acquisition will allow the newly restructured Cone Denim to offer a ‘fully vertical, end-to-end’ solution, providing everything from premium denim fabric to finished garments. It will also expand its global footprint, with operations in North America, Asia, and potentially North Africa. Additionally, there are plans to revive US production capabilities.

The recent Intertextile Shanghai Apparel Fabrics, Autumn Edition, held from September 2-5, 2025, served as a powerful platform to validate a significant shift in the global textile landscape: the strategic partnership between China and the ASEAN bloc. The exhibition and its related forums, particularly the key session on "Opportunities in ASEAN in a Changing Trade Environment", underscored China's evolving strategy to solidify its dominance not by being the sole producer, but by controlling the upstream textile supply chain and leveraging ASEAN as its primary manufacturing hub. This is the core of the "China + ASEAN" alliance, a more accurate representation of the "China +1" strategy in action.

A strategic alliance born from economic realities

With rising domestic labor costs, China has shifted its focus to the production of high-quality fibers, yarns, and fabrics. This move is a strategic plan to maintain control over the global textile value chain. ASEAN, with its cost-competitive labor and growing manufacturing capacity, is the perfect partner for this strategy.

The data and related reports confirm this symbiotic relationship. An expert at the Intertextile forum articulated the new paradigm: " China plus one is ASEAN, rather being endorsed and supported by China itself with the large investments and supplies of raw material?" This context highlights a central theme: the bloc's emergence is not coincidental but a result of deliberate support from China.

China's Textile (Fibers, Yarns, Fabrics) Exports: Top Destinations

|

Destination |

2022 Export Value (USD Billions) |

2023 Export Value (USD Billions) |

2024 Export Value (USD Billions) |

|

ASEAN Bloc |

$58.00 |

$53.18 |

$54.9 (Est.)* |

|

United States |

$52.03 |

$49.40 |

$48.10 |

|

European Union |

$35.87 |

$30.76 |

$30.8* (Est.) |

|

Japan |

$19.57 |

$15.40 |

$15.40 |

|

Bangladesh |

$9.37 |

$9.22 |

$9.22 |

Note: 2024 figures are projections based on recent trends.

The data clearly illustrates this strategic plan in action. ASEAN has emerged as the number one export destination for China's textile goods, surpassing traditional markets like the U.S. and the E.U. This is a direct result of China's strategy to provide the inputs that fuel ASEAN's manufacturing machine.

Xu Yingxin, Vice President of the China National Textile and Apparel Council, presented compelling data during the event, noting that in 2024, China's and the "East China Sea countries'" (a direct reference to the ASEAN bloc) textile and clothing export trade totaled $596.5 billion, a 6.7% growth rate. This is faster than the overall Chinese textile industry's global trade increase of 4.2%, showcasing the strategic prioritization of the ASEAN partnership.

China's Investment Footprint in ASEAN: Securing the alliance

To ensure the success of this strategic move, China has become a top foreign investor in the ASEAN textile and apparel sector, creating a ready and reliable market for its textile exports.

● Strategic relocation: Chinese companies are investing heavily in ASEAN to bypass tariffs and leverage lower labor costs. In some cases, this investment is overwhelming. According to the forum interaction, a large number of garment factories in Cambodia are owned by Chinese companies or investors. This level of ownership ensures that China's textile exports have a ready and reliable market.

● Upstream control: As Xu mentioned, "According to available statistics, since 2013, China's textile industry has accumulated direct investment of more than $5.6 billion in the East China Sea". This investment in spinning, weaving, and dyeing facilities helps to build a vertically integrated supply chain within ASEAN, solidifying China's control.

● A Frontrunner in FDI: While the U.S. is the largest overall investor in ASEAN, China's manufacturing FDI in the bloc has been growing at a rapid pace. This is not just about capital; it's about supply chain control.

ASEAN's Emergence: The resilient "China +1" bloc

The data below shows that while ASEAN produces the finished goods, it exports them primarily to Western markets, completing the global value chain cycle orchestrated by China. This win-win situation was highlighted in the forum, with a speaker noting that "China has created a win-win situation with ASEAN growing as a bloc".

Leading destinations for ASEAN's apparel exports

|

Destination Country |

Estimated Share of ASEAN's Apparel Exports (2022) |

|

USA |

~49% |

|

Japan |

~10.1% |

|

China |

~2.05% |

|

France |

~1.78% |

|

Others |

Remaining share |

By leveraging China's inputs and investments, ASEAN has become a powerful apparel manufacturing hub. This collective strength makes it a more resilient and strategic alternative to any single country like Bangladesh.

ASEAN (as a Bloc) vs. Bangladesh as "China +1"

|

Feature |

ASEAN (as a Bloc) |

Bangladesh |

|

Diversification & Resilience |

A network of countries with different strengths, providing flexibility and reducing risk. |

A single-country model with a high concentration of risk. |

|

Trade Agreements |

Benefits from the expansive RCEP, offering extensive market access to both China and other global economies. |

Relies on a limited number of FTAs and preferential access tied to its LDC status. |

|

Vertical Integration |

Growing capacity for both upstream and downstream production, making the bloc less dependent on external suppliers over time. |

Primarily a downstream manufacturer, highly dependent on imported textiles. |

|

Strategic Interdependence |

A symbiotic relationship with China, where China supplies materials and ASEAN handles manufacturing. |

A key customer for Chinese textiles, but lacks the strategic, bloc-wide integration of ASEAN. |

China not ceding its dominance; it is simply evolving its strategy

China is not ceding its dominance; it is simply evolving its strategy. By providing the materials and investing in the infrastructure of ASEAN's manufacturing, China maintains a powerful, albeit indirect, control over the global apparel supply chain. The collaboration has created a resilient, interconnected, and highly efficient ecosystem that is reshaping the future of textile and apparel trade.

The events at Intertextile Shanghai were a testament to a new era in global textiles. Messe Frankfurt's decision to organize VIATT (Vietnam International Trade Fair for Apparel, Textiles and Textile Technologies) in Vietnam is a clear endorsement of the China-ASEAN alliance. Olaf Schmidt, Vice President of Textiles & Textile Technologies at Messe Frankfurt, stated that Vietnam is "definitely a relevant market" for the textile business. He added that the launch of VIATT was aimed at "connecting the entire textile supply chain". This move is a direct acknowledgment of the evolving supply chain. As Schmidt noted, the company is carefully observing what's happening in these regions to "react" and provide the necessary platforms for collaboration.

The Hong Kong Polytechnic University (PolyU) has received a donation from the GS Charity Foundation to support a new research project focused on integrating AI and digital platforms to advance sustainable fashion. Titled ‘From Tradition to Tech: A Holistic Approach to Sustainable Fashion Design and Brand Ecosystem Management in the Age of AI and Digital Platforms,’ the project will be led by the School of Fashion and Textiles (SFT).

The project commencement ceremony was attended by Jin-Guang Teng, President, PolyU and Yeung Fan, Vice-chairman and General Manager, Glorious Sun Group. The two leaders exchanged a commemorative souvenir, a unique piece created by PolyU’s SFT and Industrial Centre. It features PolyU's architecture crafted with weaving techniques and an inscription that thanks the foundation while highlighting the university's commitment to innovation in fashion.

Teng expressed his gratitude for Glorious Sun Group and the GS Charity Foundation's long-standing support. He emphasized, AI is a core technology for Hong Kong's development and this collaboration will help produce a new generation of talent for the textile sector, equipped with both industry knowledge and AI expertise. This will help Hong Kong leverage its regional advantages and solidify the Greater Bay Area’s position as a hub for fashion innovation, he noted.

Highlighting the decades-long partnership between Glorious Sun Group and PolyU, Fan stated, the company's support for the research reflects its confidence in PolyU’s excellence. He also affirmed their shared commitment to nurturing talent and driving innovation and sustainability in the apparel industry.

Providing an overview of the research, Professor Joanne Yip, Associate Dean and Professor of SFT, explained, the fashion industry is undergoing a major transformation, adopting new technologies like AI and digital platforms to enhance efficiency, improve customer experience, and integrate sustainable practices. The research will focus on seven key areas to create innovative solutions that merge traditional design with advanced technology, ultimately boosting the industry's competitiveness.

Indian textile manufacturer Gokaldas Exports is ramping up shipments to the European Union and the United Kingdom, while increasing production in Africa, as rising US tariffs threaten profitability.

Generating roughly 75 per cent of its standalone sales from the United States and supplier to major retailers including Walmart, Gap and JCPenney, Gokuldas Exports expects its quarterly core profit margin to fall to single digits, compared with around 12 per cent in Q1, FY26.

The company produces approximately 90 million garments annually, exporting primarily to the US, Canada, the UK and France. These markets accounted for the bulk of its Rs. 38.64 billion ($438.97 million) in operating revenue during fiscal 2025.

To maintain client relationships, Gokaldas has been offering discounts and absorbing part of the additional costs linked to the higher tariffs. However, the company cautions this practice could only be sustained for a short period.

India’s $38 billion textile export industry has been hit hard by steep US tariffs, which are significantly higher than those imposed on competing countries such as Bangladesh and Vietnam, both facing a reciprocal duty of 20 per cent.

In response, Gokaldas has begun shifting portions of its production to Kenya and Ethiopia, where tariffs remain lower at a baseline of 10 per cent, following requests from clients to source from Africa.

The company is also increasing exports to the UK and EU, targeting a doubling of their combined revenue share from 10 per cent within two years, aided by the rollout of the UK-India Free Trade Agreement.

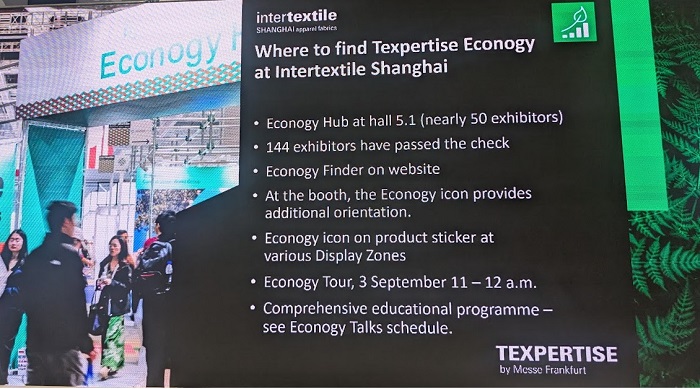

In the cavernous halls of the National Exhibition and Convention Center, a quiet but decisive shift in the textile industry’s vocabulary — and vision — was on display. Exhibitors unveiled vivid fabrics, innovative fibres, and recycling technologies, but the buzzword binding it all together was new: “Econogy.”

Coined by Messe Frankfurt, the organiser behind Intertextile Shanghai Apparel Fabrics, Econogy fuses ecology and economy. It signals that sustainability is no longer a feel-good extra but the engine of competitiveness in global textiles. “Sustainability is no longer a bonus — it’s a must,” said Olaf Schmidt, Vice President of Textiles & Textile Technologies at Messe Frankfurt, in his keynote address. “A product, however green, won’t survive if it isn’t economically viable. Econogy is about aligning those imperatives.”

From Ecology to Econogy: A strategic pivot

Messe Frankfurt’s sustainability work dates back years through its Texpertise Ecology initiatives. But 2025 marked the acceleration of a new phase: Texpertise Econogy, an umbrella framework uniting eco-driven exhibitors, certification schemes, and educational content across its global textile fairs.

At the heart of this strategy are tools designed to embed credibility and traceability:

At the heart of this strategy are tools designed to embed credibility and traceability:

● Econogy Check – an independent audit aligned with over 100 global standards, allowing exhibitors to validate claims and showcase sustainable credentials.

● Econogy Finder – an online sourcing directory for buyers seeking verified eco-friendly materials or processes.

● Econogy Hub – a dedicated show zone where suppliers, certifiers, and technology providers meet to display innovations and certifications.

● Econogy Talks & Tours – curated seminars, panels, and guided walks, translating sustainability into business practice.

The footprint of these initiatives is expanding fast. The Econogy Hub at Intertextile Shanghai grew by 70% over its debut, hosting nearly 50 exhibitors, including certification heavyweights Bureau Veritas, GOTS, TESTEX, Hohenstein, and Control Union.

Innovation takes centre stage

The fair floor revealed a surge of material and process innovation aimed at balancing environmental stewardship with commercial scale:

The fair floor revealed a surge of material and process innovation aimed at balancing environmental stewardship with commercial scale:

● Pyrus Biotech showcased bio-leather and plant-fibre textiles made from agricultural residues.

● Florence Biochem introduced microbial dyeing technology, replacing chemical-intensive processes with bio-based pigments.

● HKRITA’s “Green Machine” demonstrated a hydrothermal system for recycling blended fabrics.

● Alternatives such as Piñatex (pineapple-leaf leather), Kelsun (seaweed fibre), and Seawool (oyster-shell and PET yarn) underscored how waste streams can fuel high-performance textiles.

Digital solutions also drew attention, with platforms streamlining supply chains and cutting resource use.

Pressures driving the shift

Behind the showcase lies an urgent reality. Stricter legislation — from EU green-claims directives to global supply-chain due diligence rules — is compelling brands to prove sustainable sourcing and labour standards. Consumers, particularly younger demographics, are demanding transparency and responsible production.

Yet the path is complex:

● Verification and data remain uneven, especially for small and mid-sized manufacturers in loosely regulated regions.

● Cost pressures often clash with sustainability investments, demanding creative business models.

● Cultural and technical skills must evolve, from dye-house workers learning low-impact processes to designers adopting circularity.

Without credible tools, greenwashing risks erode trust, making verification platforms like Econogy Check vital.

Numbers that tell the story

Intertextile’s Autumn 2025 edition drew over 3,700 exhibitors from 26 economies, with a notable surge in space devoted to sustainable materials and traceable supply chains. Certified labels such as Made-in-Green and GOTS featured prominently, reflecting growing buyer demand for verifiable sustainability.

Messe Frankfurt’s own efforts mirror the ethos: a corporate code to cut energy and waste, partnerships with the UN Office for Partnerships since 2019, and reports like Texpertise Econogy Insights, which maps challenges from fibre impact to recycling solutions.

Building the future of “Econogy”

Schmidt acknowledged that scaling Econogy will take time: extending audits to more suppliers, ensuring global supply chains comply, and embedding sustainability metrics (carbon, water, labour) into decision-making. But he argued the opportunity outweighs the hurdles.

Firms that align ecology with profitability stand to gain:

● Brand value through credible eco-claims.

● Risk mitigation against regulation or raw-material shocks.

● Operational savings via reduced water, energy, and waste.

● Market access in regions where traceable eco-products are now standard.

A turning point

Intertextile Shanghai 2025 felt less like a trade fair and more like a blueprint for textiles’ next chapter. By putting structure — and economic rationale — behind sustainability, Messe Frankfurt is signalling that “Econogy” is here to stay.

As Schmidt put it, the industry is no longer talking about sustainability as a slogan. It is building systems, skills, and incentives to make it measurable, credible, and profitable. The task ahead is to scale these models globally — but the direction is clear: a textile economy where ecology is not sacrificed for growth, but drives it.